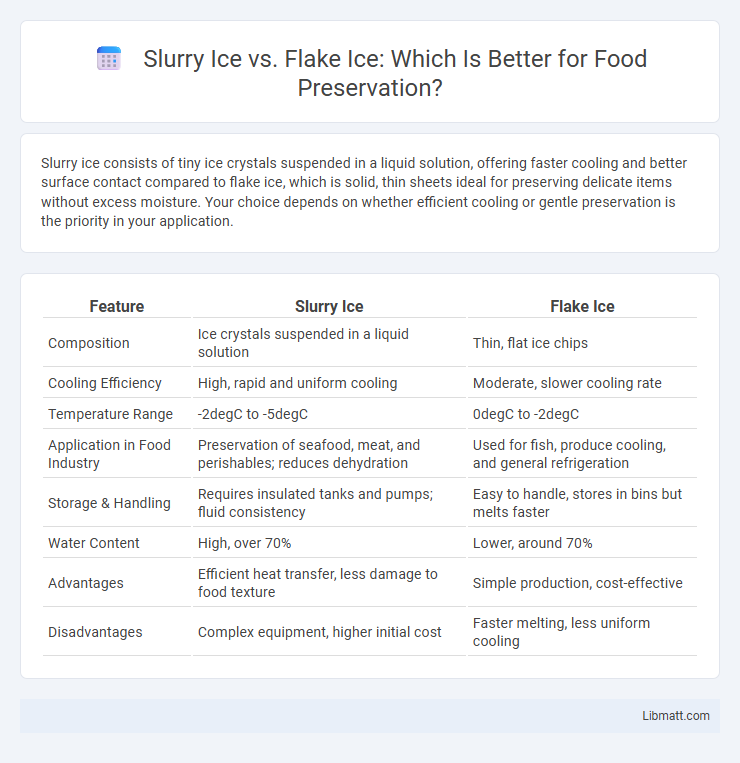

Slurry ice consists of tiny ice crystals suspended in a liquid solution, offering faster cooling and better surface contact compared to flake ice, which is solid, thin sheets ideal for preserving delicate items without excess moisture. Your choice depends on whether efficient cooling or gentle preservation is the priority in your application.

Table of Comparison

| Feature | Slurry Ice | Flake Ice |

|---|---|---|

| Composition | Ice crystals suspended in a liquid solution | Thin, flat ice chips |

| Cooling Efficiency | High, rapid and uniform cooling | Moderate, slower cooling rate |

| Temperature Range | -2degC to -5degC | 0degC to -2degC |

| Application in Food Industry | Preservation of seafood, meat, and perishables; reduces dehydration | Used for fish, produce cooling, and general refrigeration |

| Storage & Handling | Requires insulated tanks and pumps; fluid consistency | Easy to handle, stores in bins but melts faster |

| Water Content | High, over 70% | Lower, around 70% |

| Advantages | Efficient heat transfer, less damage to food texture | Simple production, cost-effective |

| Disadvantages | Complex equipment, higher initial cost | Faster melting, less uniform cooling |

Introduction to Slurry Ice and Flake Ice

Slurry ice consists of tiny ice crystals suspended in a liquid solution, offering rapid cooling and uniform temperature control ideal for seafood and medical applications. Flake ice, characterized by thin, flat ice pieces, provides excellent surface contact for preserving freshness in produce and fish industries. Understanding the differences between slurry ice and flake ice helps optimize Your cooling systems for efficiency and product quality.

Composition and Structure Differences

Slurry ice consists of microcrystals of ice suspended in a liquid solution, usually water mixed with a freezing point depressant, resulting in a flexible, pumpable slurry. Flake ice is composed of thin, flat ice pieces with a high surface area, produced by freezing water on a cold surface and scraping off the ice layer. The amorphous, semi-liquid nature of slurry ice allows improved contact and cooling efficiency compared to the solid, rigid structure of flake ice.

Production Methods and Technologies

Slurry ice is produced by mixing finely crushed ice crystals with a freezing point depressant liquid, using specialized ice slurrying machines that control ice crystal size and concentration. Flake ice is manufactured through mechanical scraping of ice from a cooled drum or plate surface, resulting in thin, flat ice pieces ideal for immediate use. Advanced slurry ice systems use indirect refrigeration and precise temperature control, while flake ice machines rely on direct contact freezing and mechanical scrapers for continuous ice production.

Cooling Efficiency and Temperature Control

Slurry ice offers superior cooling efficiency due to its small ice crystals suspended in a brine solution, enabling rapid and uniform heat transfer compared to flake ice, which consists of larger, less homogeneous ice particles. Temperature control with slurry ice is more precise since it maintains consistent contact with the product, minimizing temperature fluctuations and reducing thermal shock. Your cooling processes can benefit from improved energy savings and product quality by choosing slurry ice over traditional flake ice for applications requiring exact temperature regulation.

Application Areas in Various Industries

Slurry ice is widely used in the seafood and fishing industries due to its excellent cooling efficiency and ability to reach difficult product surfaces, preserving freshness and quality. Flake ice is preferred in meat processing, food preservation, and concrete cooling applications because of its large surface area and gentle cooling properties. Your choice between slurry ice and flake ice depends on the specific cooling needs and handling requirements of your industry.

Preservation of Product Quality

Slurry ice offers superior preservation of product quality compared to flake ice due to its smaller, uniform ice crystals and rapid cooling capability, which reduce cellular damage in seafood and perishable goods. Its ability to fill irregular spaces around products ensures consistent temperature maintenance, minimizing spoilage and dehydration. Using slurry ice improves your product's freshness and shelf life, crucial for maintaining high standards in food storage and transportation.

Energy Consumption and Cost Comparison

Slurry ice systems typically consume 20-30% less energy compared to flake ice machines due to their efficient heat transfer and reduced freezing capacity. The operational cost of slurry ice is lower, driven by decreased maintenance needs and higher production rates per kWh. Capital investment for slurry ice units can be higher upfront, but long-term savings in energy and reduced labor provide a favorable total cost of ownership relative to flake ice solutions.

Environmental Impact and Sustainability

Slurry ice offers a more energy-efficient cooling solution compared to flake ice, reducing overall carbon emissions during production. Flake ice typically requires more electricity and water, leading to a higher environmental footprint and resource consumption. By choosing slurry ice, you can support sustainability efforts and minimize environmental impact in industrial or commercial cooling applications.

Maintenance and Operational Considerations

Slurry ice systems require regular monitoring of the coolant mixture to prevent corrosion and maintain pump efficiency, while flake ice machines demand frequent cleaning to avoid scale buildup on freezing surfaces. Slurry ice offers energy-efficient operation with fewer moving parts, resulting in reduced mechanical wear compared to the flake ice's more complex scraping mechanisms. Both systems necessitate scheduled maintenance, but slurry ice typically involves less downtime, enhancing operational productivity in industrial refrigeration applications.

Choosing the Right Ice Type for Your Needs

Slurry ice offers superior cooling efficiency and flexibility by combining water and fine ice crystals, making it ideal for rapid chilling and uniform temperature control in seafood preservation and pharmaceutical applications. Flake ice, known for its dry, soft texture and large surface area, excels in food processing and display due to its gentle cooling and easy moldability around products. Selecting slurry ice or flake ice depends on specific requirements like cooling speed, product type, storage conditions, and handling preferences, ensuring optimal freshness and operational efficiency.

Slurry Ice vs Flake Ice Infographic

libmatt.com

libmatt.com