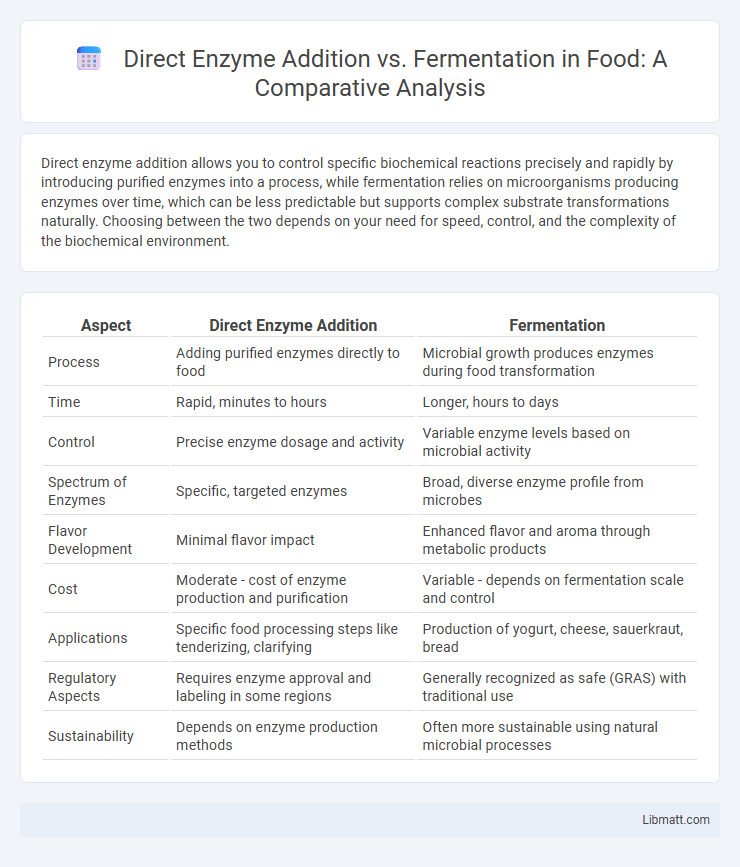

Direct enzyme addition allows you to control specific biochemical reactions precisely and rapidly by introducing purified enzymes into a process, while fermentation relies on microorganisms producing enzymes over time, which can be less predictable but supports complex substrate transformations naturally. Choosing between the two depends on your need for speed, control, and the complexity of the biochemical environment.

Table of Comparison

| Aspect | Direct Enzyme Addition | Fermentation |

|---|---|---|

| Process | Adding purified enzymes directly to food | Microbial growth produces enzymes during food transformation |

| Time | Rapid, minutes to hours | Longer, hours to days |

| Control | Precise enzyme dosage and activity | Variable enzyme levels based on microbial activity |

| Spectrum of Enzymes | Specific, targeted enzymes | Broad, diverse enzyme profile from microbes |

| Flavor Development | Minimal flavor impact | Enhanced flavor and aroma through metabolic products |

| Cost | Moderate - cost of enzyme production and purification | Variable - depends on fermentation scale and control |

| Applications | Specific food processing steps like tenderizing, clarifying | Production of yogurt, cheese, sauerkraut, bread |

| Regulatory Aspects | Requires enzyme approval and labeling in some regions | Generally recognized as safe (GRAS) with traditional use |

| Sustainability | Depends on enzyme production methods | Often more sustainable using natural microbial processes |

Introduction to Direct Enzyme Addition and Fermentation

Direct enzyme addition involves supplementing specific enzymes directly into your process to accelerate biochemical reactions, providing immediate and controlled activity. Fermentation relies on microorganisms to naturally produce enzymes as they metabolize substrates, often resulting in complex enzyme mixtures tailored by microbial growth conditions. Both methods offer distinct advantages depending on the desired enzyme profile, timing, and process control requirements.

Defining Direct Enzyme Addition

Direct enzyme addition involves incorporating specific enzymes directly into a process to catalyze biochemical reactions rapidly and with precise control. Unlike fermentation, which relies on microbial activity to produce enzymes over time, this method provides immediate enzyme availability, enhancing efficiency and consistency in your operations. This approach optimizes reaction rates and product quality by delivering targeted enzymatic activity without the variability associated with microbial growth.

Understanding Enzyme Production through Fermentation

Enzyme production through fermentation involves using microorganisms like bacteria, fungi, or yeast to biosynthesize specific enzymes under controlled conditions, maximizing yield and activity. Direct enzyme addition bypasses in situ synthesis, providing immediate catalytic effects but lacks the adaptive optimization seen in fermentation-derived enzymes. Understanding fermentation processes enables enhanced enzyme stability, specificity, and scalability critical for industrial applications in pharmaceuticals, biofuels, and food processing.

Mechanisms of Action: Direct Addition vs. Fermentation

Direct enzyme addition involves the immediate introduction of purified enzymes into a substrate, allowing precise control over enzymatic activity and reaction time. In contrast, fermentation relies on microbial metabolism to produce enzymes in situ, enabling continuous enzyme generation and complex biochemical transformations. The direct method offers rapid and predictable action, while fermentation provides a dynamic environment for enzyme synthesis and multifunctional catalysis.

Efficiency and Yield Comparison

Direct enzyme addition offers rapid substrate conversion, leading to higher efficiency by minimizing processing time compared to fermentation, which relies on microbial growth and enzyme production stages. Your yield often improves with direct enzyme use due to consistent enzyme activity and reduced degradation, while fermentation may experience variability from microbial conditions. Enzyme addition ensures precise control over reaction parameters, optimizing overall yield productivity in industrial applications.

Cost Implications and Economic Viability

Direct enzyme addition reduces upfront capital investment by eliminating the need for specialized fermentation infrastructure, lowering initial expenditure. Fermentation, while potentially cheaper per unit enzyme produced, demands ongoing operational costs including media, sterilization, and longer production cycles, impacting overall economic viability. Evaluating cost implications involves balancing enzyme purity and activity benefits of direct addition against scalability and long-term savings offered by fermentation-based enzyme production.

Impact on Product Quality and Consistency

Direct enzyme addition ensures precise control over enzymatic activity, resulting in consistent product quality by minimizing variability in fermentation parameters. Fermentation relies on microbial metabolism, which can introduce fluctuations due to variable microbial growth and enzyme production rates, potentially affecting flavor, texture, and overall quality. Your choice impacts the predictability and uniformity of the final product, with direct enzyme usage offering enhanced consistency compared to traditional fermentation methods.

Environmental and Sustainability Considerations

Direct enzyme addition reduces resource consumption and waste generation by providing precise biochemical reactions without requiring large-scale biomass cultivation. Fermentation involves extensive use of substrates, water, and energy, contributing to higher carbon emissions and environmental footprint. Your choice of direct enzyme addition can enhance sustainability by minimizing resource input and reducing greenhouse gas emissions in industrial processes.

Industry Applications: Food, Feed, and Beyond

Direct enzyme addition offers precise control and rapid action in food processing, improving product texture, flavor, and shelf-life with applications in baking, dairy, and brewing industries. Fermentation harnesses microbial activity to naturally produce enzymes and bioactive compounds essential for probiotics, specialty feeds, and sustainable biofuels. Both methods are pivotal in expanding enzyme use beyond food and feed, including pharmaceuticals, waste management, and textile industries, driving innovation through tailored biocatalysts.

Future Trends and Innovations in Enzyme Utilization

Future trends in enzyme utilization emphasize integrating direct enzyme addition with advanced fermentation technologies to enhance efficiency and sustainability in industrial processes. Innovations include genetically engineered enzymes with improved specificity and stability, enabling precise catalytic actions during fermentation, reducing processing times and energy consumption. Emerging methods leverage automation and real-time monitoring to optimize enzyme dosages, maximizing yield and minimizing waste across food, biofuel, and pharmaceutical applications.

direct enzyme addition vs fermentation Infographic

libmatt.com

libmatt.com