Wet glazing involves applying a liquid sealant or putty to secure glass panes, providing excellent waterproofing and flexibility for irregular shapes. Dry glazing uses rubber gaskets or pre-formed strips to hold the glass, offering quicker installation and easier maintenance, making your choice dependent on the project's durability and aesthetic requirements.

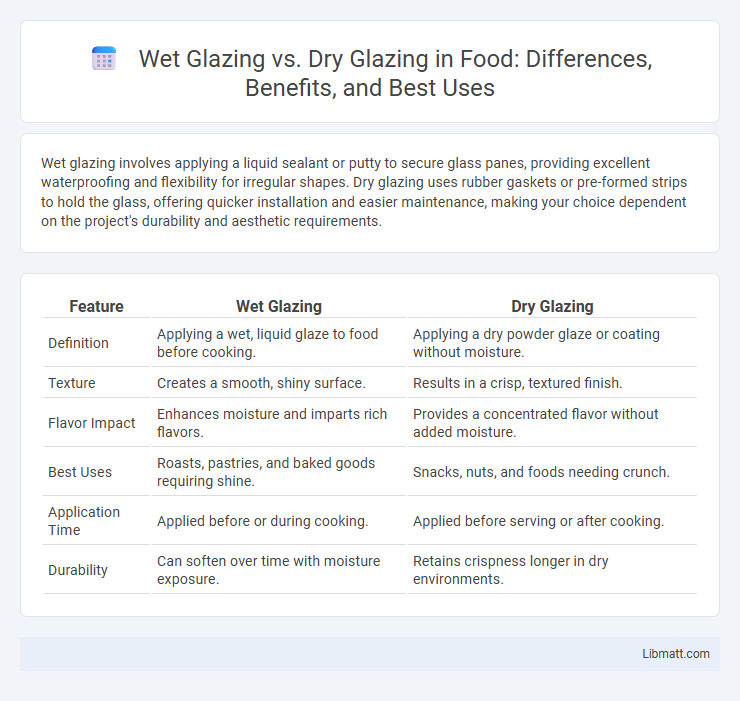

Table of Comparison

| Feature | Wet Glazing | Dry Glazing |

|---|---|---|

| Definition | Applying a wet, liquid glaze to food before cooking. | Applying a dry powder glaze or coating without moisture. |

| Texture | Creates a smooth, shiny surface. | Results in a crisp, textured finish. |

| Flavor Impact | Enhances moisture and imparts rich flavors. | Provides a concentrated flavor without added moisture. |

| Best Uses | Roasts, pastries, and baked goods requiring shine. | Snacks, nuts, and foods needing crunch. |

| Application Time | Applied before or during cooking. | Applied before serving or after cooking. |

| Durability | Can soften over time with moisture exposure. | Retains crispness longer in dry environments. |

Introduction to Glazing Systems

Wet glazing involves applying a liquid sealant, such as silicone or polyurethane, to secure glass panes within frames, offering superior weatherproofing and flexibility. Dry glazing uses pre-applied rubber gaskets or glazing tapes to hold glass in place, enabling faster installation and easier replacement. Your choice between wet and dry glazing impacts the durability, maintenance, and thermal performance of window and curtain wall systems.

What is Wet Glazing?

Wet glazing is a method of sealing glass panes using liquid sealants such as silicone or polyurethane, creating a durable and flexible bond that prevents water and air infiltration. This technique is commonly used in window installation and repair to enhance weather resistance and structural integrity. Understanding wet glazing helps ensure your glazing projects achieve optimal performance and longevity.

What is Dry Glazing?

Dry glazing is a window installation method where the glass pane is secured using rubber gaskets or sealants without the use of wet materials like silicone or putty. This technique offers faster installation times and improved weather resistance due to the elimination of curing periods associated with wet glazing compounds. Commonly used in commercial buildings, dry glazing enhances energy efficiency by providing better sealing against air and moisture infiltration.

Key Differences Between Wet and Dry Glazing

Wet glazing uses a liquid sealant such as silicone or polyurethane to secure glass panes, providing superior waterproofing and flexibility. Dry glazing relies on pre-formed gaskets or rubber seals that are easier to install and require less maintenance but may be less effective in extreme weather conditions. Your choice between wet and dry glazing impacts durability, installation time, and energy efficiency, making it essential to consider project-specific needs.

Advantages of Wet Glazing

Wet glazing offers superior adhesion and improved weatherproofing by creating a continuous seal between glass and frame, which enhances durability and energy efficiency. The use of silicone or other sealants in wet glazing absorbs shocks and accommodates building movement, reducing the risk of cracks or leaks. This method provides a more flexible and long-lasting solution compared to dry glazing, which relies on mechanical fasteners or gaskets.

Advantages of Dry Glazing

Dry glazing offers superior ease of installation compared to wet glazing, eliminating the need for curing times associated with sealants or adhesives. It provides enhanced durability and requires less maintenance due to the absence of liquid compounds that may degrade or crack over time. This method also ensures cleaner, faster application with minimal mess, making it ideal for both residential and commercial glazing projects.

Limitations of Wet Glazing

Wet glazing limitations include longer curing times, which can delay project completion and increase labor costs. Exposure to moisture during the curing process may cause adhesion issues or sealant failure, compromising the window's weather resistance. Wet glazing also requires skilled application to avoid uneven sealant distribution, leading to potential air and water leaks.

Limitations of Dry Glazing

Dry glazing limits design flexibility due to the use of rigid silicone gaskets or tapes that restrict glass movement and expansion. It offers reduced weather resistance compared to wet glazing, making it less effective in harsh or extreme climates. The method is often unsuitable for large, heavy glass panels because it cannot provide the same structural support and durability as wet glazing systems.

Best Applications for Wet and Dry Glazing

Wet glazing is best suited for exterior windows and applications requiring strong weatherproofing, as it uses silicone or other sealants to create a durable, airtight bond. Dry glazing excels in interior installations or temporary setups where quick, clean, and easy glass replacement is needed without curing time. Your choice depends on whether you prioritize long-term durability or faster, flexible installation.

Choosing the Right Glazing Method for Your Project

Choosing the right glazing method depends on factors like project scope, weather conditions, and desired durability. Wet glazing offers superior air and water tightness through silicone or polyurethane sealants, ideal for large or complex window installations. Dry glazing uses pre-fitted gaskets and is faster to install, making it suitable for projects requiring quick turnaround and easier maintenance.

Wet Glazing vs Dry Glazing Infographic

libmatt.com

libmatt.com