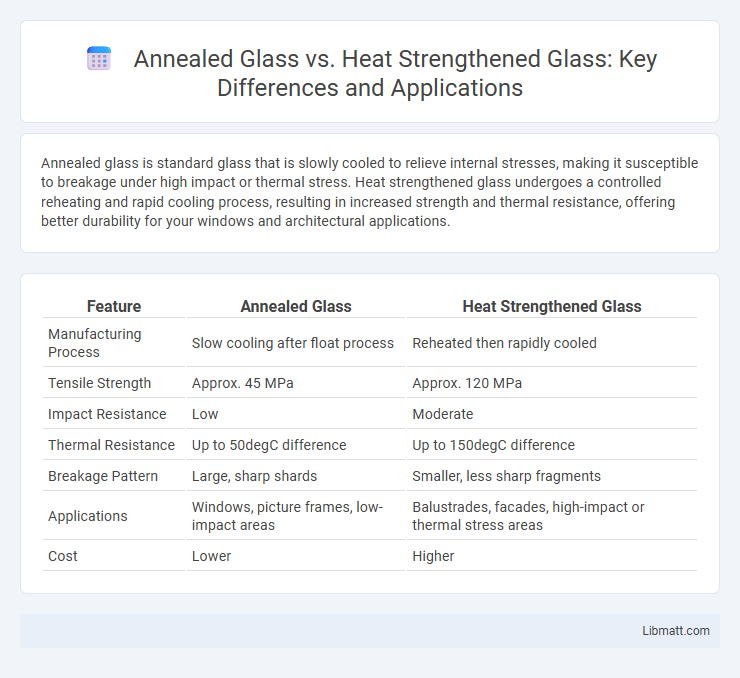

Annealed glass is standard glass that is slowly cooled to relieve internal stresses, making it susceptible to breakage under high impact or thermal stress. Heat strengthened glass undergoes a controlled reheating and rapid cooling process, resulting in increased strength and thermal resistance, offering better durability for your windows and architectural applications.

Table of Comparison

| Feature | Annealed Glass | Heat Strengthened Glass |

|---|---|---|

| Manufacturing Process | Slow cooling after float process | Reheated then rapidly cooled |

| Tensile Strength | Approx. 45 MPa | Approx. 120 MPa |

| Impact Resistance | Low | Moderate |

| Thermal Resistance | Up to 50degC difference | Up to 150degC difference |

| Breakage Pattern | Large, sharp shards | Smaller, less sharp fragments |

| Applications | Windows, picture frames, low-impact areas | Balustrades, facades, high-impact or thermal stress areas |

| Cost | Lower | Higher |

Introduction to Annealed and Heat Strengthened Glass

Annealed glass is a basic, untreated glass that cools slowly to relieve internal stresses, making it more prone to breakage upon impact. Heat-strengthened glass undergoes a controlled thermal treatment process, increasing its strength to approximately twice that of annealed glass, while maintaining a similar break pattern. Understanding these differences helps you choose the right glass type for safety, durability, and performance in architectural applications.

Manufacturing Processes Compared

Annealed glass is produced through a slow cooling process after heating, allowing internal stresses to be minimized naturally, resulting in standard strength and clarity. Heat strengthened glass undergoes a controlled reheating to about 650degC followed by rapid air cooling, which increases its strength by inducing compressive stresses on the surface while maintaining a lower risk of breakage compared to fully tempered glass. Your choice depends on the required safety, strength, and thermal resistance characteristics driven by these distinct manufacturing techniques.

Physical Properties and Strength

Annealed glass is a standard float glass that cools slowly to relieve internal stresses, resulting in lower strength and higher susceptibility to breakage under impact or thermal stress. Heat strengthened glass undergoes controlled heating and rapid cooling, providing approximately twice the strength of annealed glass and improved resistance to mechanical stress and thermal fluctuations. While annealed glass typically has a tensile strength of around 45 MPa, heat strengthened glass can reach tensile strengths up to 120 MPa, making it suitable for applications requiring higher safety and durability.

Safety and Breakage Characteristics

Annealed glass breaks into large, sharp shards that pose a significant safety hazard, as it lacks any strengthening process. Heat strengthened glass undergoes controlled thermal treatment, making it about twice as strong as annealed glass and causing it to fracture into larger, less dangerous pieces compared to tempered glass. Your choice between these glass types should consider the required safety level and the specific application's breakage characteristics to minimize injury risk.

Applications in Architecture and Industry

Annealed glass is commonly used in interior architectural applications such as picture frames, windows, and decorative panels where strength is less critical, providing clarity and ease of fabrication. Heat strengthened glass offers increased resistance to thermal stress and mechanical loads, making it suitable for applications like building facades, skylights, and industrial equipment glazing that demand improved safety without the full durability of tempered glass. Your choice depends on balancing cost, performance requirements, and safety codes specific to architectural or industrial environments.

Cost Differences and Budget Considerations

Annealed glass is generally more cost-effective than heat strengthened glass due to lower manufacturing complexity and processing time, making it suitable for budget-conscious projects. Heat strengthened glass, offering enhanced strength and thermal resistance, commands a higher price point that reflects these performance benefits. Budget considerations should weigh the initial cost savings of annealed glass against the potential long-term durability and safety advantages of heat strengthened glass in applications subject to stress or thermal variations.

Thermal Performance and Resistance

Annealed glass offers lower thermal resistance and is more prone to breakage under thermal stress compared to heat strengthened glass. Heat strengthened glass undergoes a thermal tempering process that enhances its ability to withstand higher temperature fluctuations and thermal shock. This increased thermal performance makes heat strengthened glass suitable for applications requiring improved durability and safety in environments with varying temperatures.

Code Compliance and Industry Standards

Annealed glass meets basic safety standards but lacks sufficient impact resistance required by many building codes, making it unsuitable for applications demanding higher strength and safety. Heat-strengthened glass complies with stringent building codes like ASTM C1048 and meets safety regulations for wind loads, thermal stress, and human impact resistance in commercial and residential construction. The increased durability of heat-strengthened glass ensures adherence to industry standards such as ANSI Z97.1 and CPSC 16 CFR 1201, which are crucial for occupant protection and structural integrity.

Lifespan and Maintenance Needs

Annealed glass generally has a shorter lifespan due to its lower resistance to thermal and mechanical stress, often requiring more frequent replacement or repair in demanding environments. Heat strengthened glass offers enhanced durability and longer lifespan by undergoing controlled thermal treatment, which increases its strength to approximately twice that of annealed glass. Maintenance needs for heat strengthened glass are typically lower, as its improved resistance to impacts and temperature fluctuations reduces the likelihood of damage and associated upkeep.

Choosing the Right Glass for Your Project

Annealed glass is softer and more prone to breakage, making it ideal for applications where cost-effectiveness and ease of cutting are priorities. Heat strengthened glass offers enhanced strength--approximately twice that of annealed glass--suitable for projects requiring increased durability and impact resistance without the high cost of tempered glass. Your choice depends on the specific safety, strength, and performance needs of your architectural or design project.

annealed glass vs heat strengthened glass Infographic

libmatt.com

libmatt.com