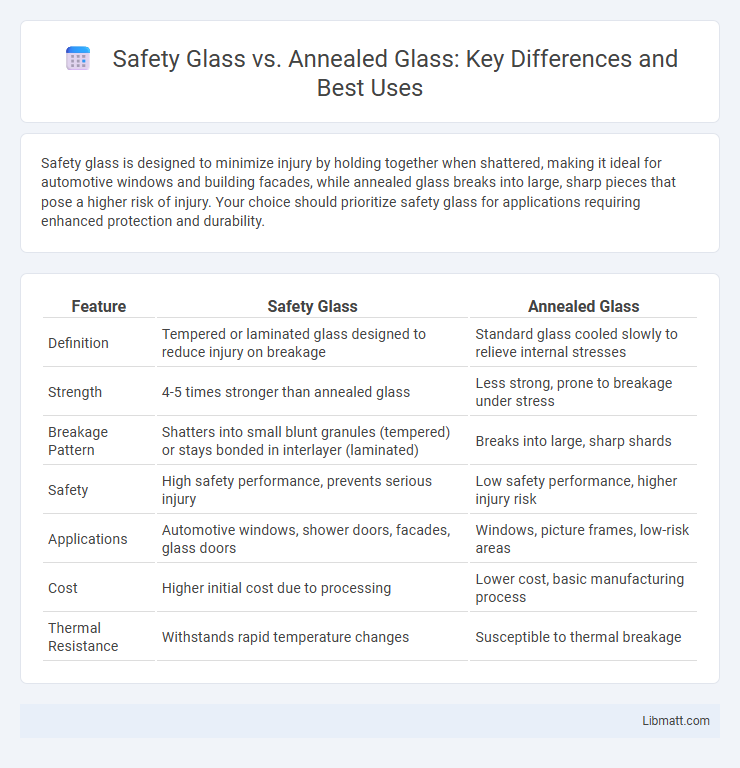

Safety glass is designed to minimize injury by holding together when shattered, making it ideal for automotive windows and building facades, while annealed glass breaks into large, sharp pieces that pose a higher risk of injury. Your choice should prioritize safety glass for applications requiring enhanced protection and durability.

Table of Comparison

| Feature | Safety Glass | Annealed Glass |

|---|---|---|

| Definition | Tempered or laminated glass designed to reduce injury on breakage | Standard glass cooled slowly to relieve internal stresses |

| Strength | 4-5 times stronger than annealed glass | Less strong, prone to breakage under stress |

| Breakage Pattern | Shatters into small blunt granules (tempered) or stays bonded in interlayer (laminated) | Breaks into large, sharp shards |

| Safety | High safety performance, prevents serious injury | Low safety performance, higher injury risk |

| Applications | Automotive windows, shower doors, facades, glass doors | Windows, picture frames, low-risk areas |

| Cost | Higher initial cost due to processing | Lower cost, basic manufacturing process |

| Thermal Resistance | Withstands rapid temperature changes | Susceptible to thermal breakage |

Introduction to Safety Glass and Annealed Glass

Safety glass, designed to minimize injury upon breakage, includes tempered and laminated types commonly used in vehicles and architectural applications. Annealed glass undergoes slow cooling to relieve internal stresses but can shatter into dangerous shards, making it less safe for impact-prone environments. Your choice between safety glass and annealed glass impacts durability, safety standards, and regulatory compliance in construction or automotive projects.

What is Annealed Glass?

Annealed glass is a type of standard, untreated glass that is slowly cooled during manufacturing to relieve internal stresses. It is more prone to breaking into sharp, dangerous shards compared to safety glass, which has been chemically or heat-treated for enhanced strength. Commonly used in windows and picture frames, annealed glass lacks the protective features necessary for high-impact or safety-critical applications.

What is Safety Glass?

Safety glass is a type of glass engineered to minimize injury during breakage by either holding shattered pieces together or breaking into small, blunt fragments. It includes tempered glass, which undergoes rapid cooling to increase strength, and laminated glass, made by sandwiching a plastic interlayer between glass sheets to prevent shattering. Widely used in automotive windows, building facades, and glass doors, safety glass meets strict industry standards for impact resistance and durability.

Manufacturing Processes Compared

Safety glass undergoes a specialized manufacturing process involving tempering or lamination, where it is either rapidly cooled after heating (tempering) or bonded with an interlayer such as polyvinyl butyral (lamination) to enhance strength and shatter resistance. Annealed glass is produced through a slower cooling process after heating, which relieves internal stresses but results in a weaker, more easily breakable material compared to safety glass. The manufacturing differences determine their applications, with safety glass providing superior impact resistance for automotive, architectural, and safety-critical environments.

Strength and Durability Differences

Safety glass, such as tempered or laminated glass, provides significantly higher strength and durability compared to annealed glass, making it more resistant to impact and thermal stress. Tempered safety glass undergoes a heat treatment process that increases its strength up to four times that of annealed glass, while laminated glass incorporates a plastic interlayer that holds shards together upon breakage, enhancing safety. Annealed glass, by contrast, is more prone to cracking or shattering under stress due to its slower cooling process and lower resistance to mechanical and thermal impacts.

Safety Features and Breakage Patterns

Safety glass incorporates a laminated or tempered structure designed to enhance impact resistance and prevent sharp shards upon breaking, significantly reducing injury risks. Annealed glass, lacking this reinforcement, shatters into large, sharp pieces that pose serious safety hazards. The specialized breakage pattern of safety glass ensures it either remains intact or breaks into small, blunt fragments, making it the preferred choice for automotive, architectural, and safety-critical applications.

Common Applications in Construction

Safety glass, including tempered and laminated types, is commonly used in high-risk areas such as building facades, skylights, and glass doors to enhance impact resistance and prevent shattering. Annealed glass is typically utilized in interior applications like windows, framed doors, and decorative installations where strength requirements are lower. Construction standards often mandate safety glass for locations near floor levels or where human impact risk is significant, ensuring occupant protection and compliance with building codes.

Cost Comparison and Value

Safety glass typically costs 20-40% more than annealed glass due to its enhanced durability and impact resistance, providing better protection in homes and vehicles. While annealed glass is more affordable upfront, safety glass offers greater long-term value by reducing injury risks and potential replacement costs after breakage. Choosing safety glass can be a smart investment that prioritizes your well-being and property security.

Maintenance and Lifespan Considerations

Safety glass, such as tempered or laminated glass, offers enhanced durability and resistance to impact, reducing the likelihood of cracks and breakage, which minimizes maintenance needs over its lifespan. Annealed glass, while more affordable, is prone to chipping and cracking under stress, often requiring more frequent inspections and replacements to maintain safety standards. The extended lifespan and lower maintenance requirements of safety glass make it a cost-effective choice for long-term applications in buildings and vehicles.

Choosing the Right Glass for Your Project

Safety glass, including tempered and laminated options, offers enhanced impact resistance and shatters into small, less harmful pieces, making it ideal for high-traffic or safety-critical installations. Annealed glass, while more affordable and easier to cut or shape, breaks into large, sharp shards that pose greater injury risks. Choosing the right glass for your project depends on balancing safety requirements, budget, and the specific environment where the glass will be used.

safety glass vs annealed glass Infographic

libmatt.com

libmatt.com