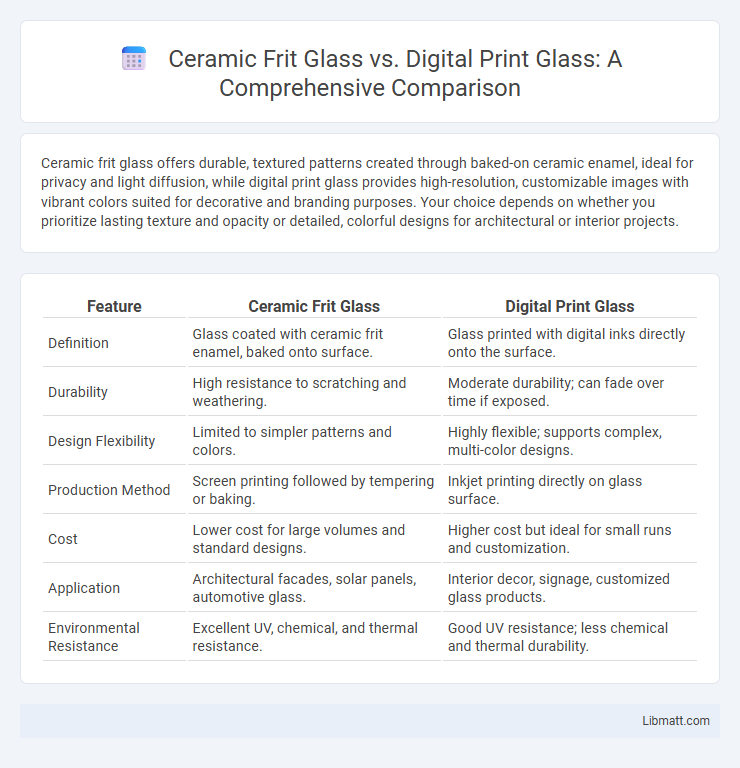

Ceramic frit glass offers durable, textured patterns created through baked-on ceramic enamel, ideal for privacy and light diffusion, while digital print glass provides high-resolution, customizable images with vibrant colors suited for decorative and branding purposes. Your choice depends on whether you prioritize lasting texture and opacity or detailed, colorful designs for architectural or interior projects.

Table of Comparison

| Feature | Ceramic Frit Glass | Digital Print Glass |

|---|---|---|

| Definition | Glass coated with ceramic frit enamel, baked onto surface. | Glass printed with digital inks directly onto the surface. |

| Durability | High resistance to scratching and weathering. | Moderate durability; can fade over time if exposed. |

| Design Flexibility | Limited to simpler patterns and colors. | Highly flexible; supports complex, multi-color designs. |

| Production Method | Screen printing followed by tempering or baking. | Inkjet printing directly on glass surface. |

| Cost | Lower cost for large volumes and standard designs. | Higher cost but ideal for small runs and customization. |

| Application | Architectural facades, solar panels, automotive glass. | Interior decor, signage, customized glass products. |

| Environmental Resistance | Excellent UV, chemical, and thermal resistance. | Good UV resistance; less chemical and thermal durability. |

Introduction to Ceramic Frit Glass and Digital Print Glass

Ceramic frit glass features a durable, fused ceramic coating applied through screen printing, offering enhanced resistance to weathering and UV radiation ideal for architectural facade applications. Digital print glass utilizes advanced inkjet technology to directly apply high-resolution designs onto the glass surface, enabling customizable patterns and gradients with superior precision. Both methods provide aesthetic versatility, but ceramic frit glass emphasizes durability and opacity, while digital print glass excels in detailed, vibrant visual effects.

Manufacturing Processes Explained

Ceramic frit glass is produced by applying a ceramic frit coating, composed of finely ground glass mixed with pigments, onto glass surfaces before high-temperature baking, which fuses the coating permanently to the glass. Digital print glass manufacturing uses advanced inkjet technology to deposit UV-curable inks or ceramic-based inks directly onto the glass, followed by curing through UV light or kiln firing to ensure durability and adhesion. Both methods achieve decorative and functional outcomes but differ in application techniques, firing temperatures, and levels of customization.

Material Composition and Techniques

Ceramic frit glass is made by fusing powdered glass mixed with ceramic pigments onto the glass surface, creating a durable and heat-resistant design through high-temperature kiln firing. Digital print glass uses UV or ceramic inks applied directly onto the glass via advanced printing technology, allowing for high-resolution and full-color images without the need for firing in some cases. Your choice depends on the desired durability and detail, as ceramic frit offers superior longevity and resistance, while digital print provides more design flexibility and intricate patterns.

Design Flexibility and Customization

Ceramic frit glass offers limited design flexibility due to its reliance on screen printing techniques that produce consistent but less intricate patterns. Digital print glass allows for high customization with detailed, multi-colored designs created directly from digital files, enabling unique and complex artwork tailored to your specific project needs. This makes digital print glass the preferred choice when precise, vibrant, and varied design options are essential.

Durability and Weather Resistance

Ceramic frit glass offers superior durability and weather resistance due to its baked-in ceramic enamel, making it highly resistant to fading, scratching, and harsh environmental conditions. Digital print glass, while offering vibrant and customizable designs, tends to have a thinner ink layer that may degrade faster under prolonged exposure to UV rays and moisture. For long-term exterior applications, ceramic frit glass maintains its aesthetic integrity and structural stability better than digital print glass.

Color Quality and Longevity

Ceramic frit glass offers superior color vibrancy and durability due to its baked-in color particles that resist fading and wear, making it ideal for long-lasting architectural applications. Digital print glass provides high-resolution, customizable color options but may be more susceptible to fading and surface damage over time if not properly protected. Your choice depends on whether you prioritize enduring color quality with ceramic frit or flexible design possibilities with digital print glass.

Applications in Architecture and Interior Design

Ceramic frit glass offers superior durability and UV resistance, making it ideal for exterior facades, shading devices, and decorative panels in architecture. Digital print glass provides high-resolution, customizable imagery that enhances interior design elements like feature walls, partitions, and glass furniture with intricate patterns and branding. Both technologies support energy-efficient solutions and aesthetic innovation, addressing contemporary demands in commercial and residential projects.

Environmental Impact and Sustainability

Ceramic frit glass offers superior environmental benefits due to its durability and resistance to fading, reducing the need for frequent replacements and minimizing waste. Digital print glass involves higher energy consumption during production and uses organic solvents that can contribute to environmental pollution. Choosing ceramic frit glass enhances sustainability through its long lifespan and lower ecological footprint compared to the resource-intensive digital printing process.

Cost Considerations and Value

Ceramic frit glass offers cost-effective durability and long-lasting color retention, making it a budget-friendly option for large-scale architectural projects. Digital print glass provides higher customization and intricate designs, but typically incurs greater production and installation costs due to advanced technology and labor. Your choice depends on balancing upfront investment with the desired aesthetic complexity and durability requirements.

Choosing the Right Glass for Your Project

Ceramic frit glass offers durability and long-lasting color retention, making it ideal for architectural facades and exterior applications requiring heat resistance and UV stability. Digital print glass provides high-resolution, customizable designs suitable for interior decoration and complex visual patterns, allowing greater artistic flexibility. Evaluating project needs, including exposure conditions and design complexity, ensures the selection of the most appropriate glass type to maximize performance and aesthetic impact.

Ceramic frit glass vs digital print glass Infographic

libmatt.com

libmatt.com