Annealed glass is standard float glass that has been slowly cooled to relieve internal stresses, making it more prone to breakage into sharp shards, whereas toughened glass undergoes a rapid cooling process to increase strength and shatters into small, blunt pieces for safety. Your choice between annealed and toughened glass depends on application requirements for durability, safety, and impact resistance.

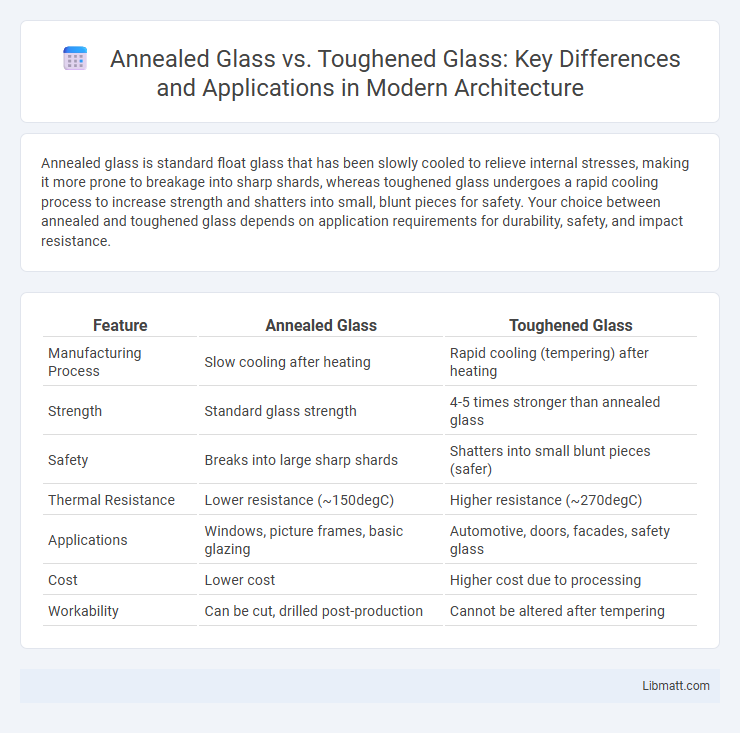

Table of Comparison

| Feature | Annealed Glass | Toughened Glass |

|---|---|---|

| Manufacturing Process | Slow cooling after heating | Rapid cooling (tempering) after heating |

| Strength | Standard glass strength | 4-5 times stronger than annealed glass |

| Safety | Breaks into large sharp shards | Shatters into small blunt pieces (safer) |

| Thermal Resistance | Lower resistance (~150degC) | Higher resistance (~270degC) |

| Applications | Windows, picture frames, basic glazing | Automotive, doors, facades, safety glass |

| Cost | Lower cost | Higher cost due to processing |

| Workability | Can be cut, drilled post-production | Cannot be altered after tempering |

Introduction to Annealed and Toughened Glass

Annealed glass is standard float glass slowly cooled to relieve internal stresses, making it easier to cut and shape but more prone to breakage. Toughened glass, also known as tempered glass, undergoes rapid cooling after heating to increase strength, offering up to four times the durability of annealed glass and breaking into small, safer fragments. Understanding these differences helps you choose the right glass type for applications requiring enhanced safety and impact resistance.

Manufacturing Process Comparison

Annealed glass undergoes a slow cooling process after being formed, allowing internal stresses to relax and resulting in a standard float glass with no enhanced strength. Toughened glass is produced by rapid cooling or quenching after heating to approximately 620degC, which creates compressive surface stresses and significantly increases its strength and safety properties. The manufacturing difference lies in annealing's slow cooling versus toughening's controlled rapid cooling, directly impacting the mechanical performance and breakage behavior of the glass.

Physical and Mechanical Properties

Annealed glass exhibits lower strength and toughness, making it more susceptible to breakage under impact or stress, while toughened glass undergoes thermal or chemical treatment to enhance its strength up to four to five times that of annealed glass. Toughened glass demonstrates higher resistance to mechanical impacts, thermal stress, and bending loads due to its induced compressive surface stresses, whereas annealed glass lacks these reinforcing stresses and breaks into large, sharp shards. The shattering pattern of toughened glass creates small, granular pieces that reduce injury risk, contrasting with the dangerous fragments produced by annealed glass, highlighting the superior safety and durability of toughened glass in structural and architectural applications.

Strength and Safety Differences

Toughened glass is significantly stronger than annealed glass, as it undergoes a heat treatment process that increases its resistance to impact and thermal stress. When broken, toughened glass shatters into small, blunt pieces that reduce the risk of injury, whereas annealed glass breaks into large, sharp shards posing higher safety hazards. Choosing toughened glass enhances your environment's safety by providing improved strength and minimizing potential harm.

Thermal Resistance and Performance

Annealed glass exhibits low thermal resistance, making it more susceptible to thermal stress and breakage under rapid temperature changes. Toughened glass undergoes controlled thermal or chemical treatments, enhancing its thermal performance by increasing strength and resistance to thermal shock. This makes toughened glass ideal for environments with high temperature fluctuations or exposure to intense heat.

Applications of Annealed Glass

Annealed glass is widely used in applications such as picture frames, windows, and skylights where safety is less critical and cost efficiency is important. It provides clarity and uniform thickness, making it ideal for decorative purposes and interior use in furniture or display cases. Due to its lack of strength compared to toughened glass, annealed glass is less suitable for structural or impact-resistant applications.

Applications of Toughened Glass

Toughened glass is widely used in applications requiring enhanced strength and safety, such as automotive windows, building facades, shower doors, and glass balustrades. Its ability to withstand high impacts and thermal stress makes it ideal for environments where safety regulations and durability are critical. You benefit from toughened glass's shatter-resistant properties, which reduce injury risks in case of breakage.

Cost Considerations and Availability

Annealed glass is generally more cost-effective due to simpler manufacturing processes and widespread availability for standard window applications. Toughened glass, while pricier, offers superior strength and safety benefits, making it essential for high-impact or building code-compliant installations. Availability of toughened glass varies by region and specific thickness requirements, often requiring longer lead times compared to readily stocked annealed glass.

Durability and Lifespan

Annealed glass, known for its standard cooling process, has lower durability due to its susceptibility to breakage under impact or thermal stress. Toughened glass undergoes rapid heating and cooling, resulting in enhanced strength and increased resistance to mechanical and thermal shocks, significantly extending its lifespan in demanding environments. Due to these properties, toughened glass is preferred in safety-critical applications, offering superior longevity and performance compared to annealed glass.

Choosing the Right Glass for Your Needs

Annealed glass offers greater clarity and is easier to cut or shape, making it ideal for decorative or non-structural applications where aesthetics are a priority. Toughened glass, also known as tempered glass, provides superior strength and safety features, resisting impact and thermal stress, which suits architectural and high-traffic environments. Selecting between annealed and toughened glass depends on factors such as safety requirements, installation environment, and desired durability for your specific project.

annealed glass vs toughened glass Infographic

libmatt.com

libmatt.com