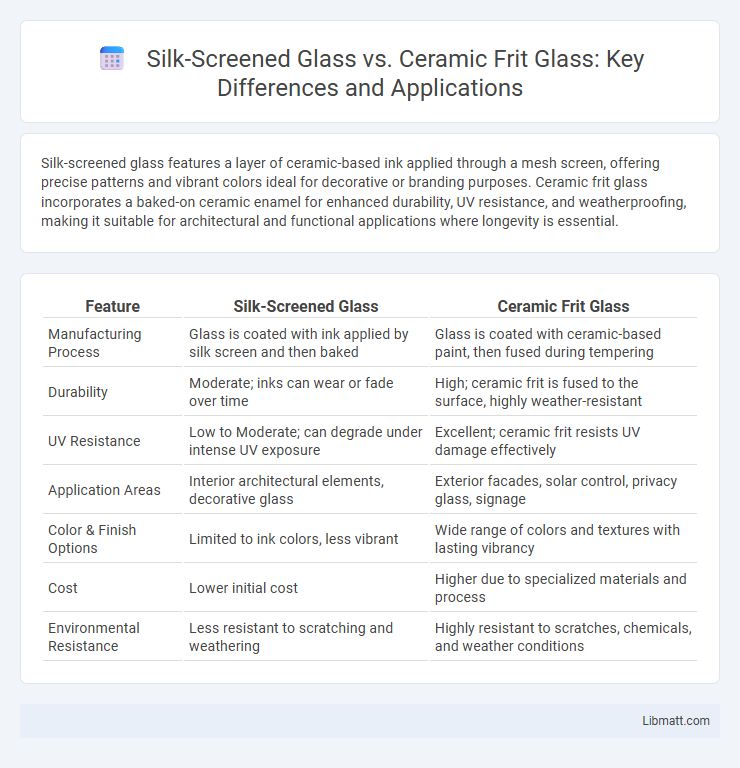

Silk-screened glass features a layer of ceramic-based ink applied through a mesh screen, offering precise patterns and vibrant colors ideal for decorative or branding purposes. Ceramic frit glass incorporates a baked-on ceramic enamel for enhanced durability, UV resistance, and weatherproofing, making it suitable for architectural and functional applications where longevity is essential.

Table of Comparison

| Feature | Silk-Screened Glass | Ceramic Frit Glass |

|---|---|---|

| Manufacturing Process | Glass is coated with ink applied by silk screen and then baked | Glass is coated with ceramic-based paint, then fused during tempering |

| Durability | Moderate; inks can wear or fade over time | High; ceramic frit is fused to the surface, highly weather-resistant |

| UV Resistance | Low to Moderate; can degrade under intense UV exposure | Excellent; ceramic frit resists UV damage effectively |

| Application Areas | Interior architectural elements, decorative glass | Exterior facades, solar control, privacy glass, signage |

| Color & Finish Options | Limited to ink colors, less vibrant | Wide range of colors and textures with lasting vibrancy |

| Cost | Lower initial cost | Higher due to specialized materials and process |

| Environmental Resistance | Less resistant to scratching and weathering | Highly resistant to scratches, chemicals, and weather conditions |

Introduction to Decorative Glass Techniques

Silk-screened glass uses a fine mesh to apply intricate patterns with ceramic-based inks that fuse to the surface during firing, offering vibrant, durable designs ideal for decorative and functional applications. Ceramic frit glass involves the application of crushed glass particles that are fused onto the glass surface in a kiln, providing textured, translucent, or opaque patterns that enhance privacy and aesthetic appeal. Your choice between silk-screened and ceramic frit glass depends on the desired visual effect, durability requirements, and specific architectural or artistic goals.

What is Silk-Screened Glass?

Silk-screened glass features a durable enamel paint applied through a mesh screen, creating precise patterns that enhance both aesthetics and solar control. Unlike ceramic frit glass, which uses fused ceramic particles during tempering, silk-screened glass allows for more intricate designs and a wider range of colors. Your choice depends on whether you prioritize customization and decorative appeal or higher heat resistance and durability.

What is Ceramic Frit Glass?

Ceramic frit glass is created by fusing a finely ground ceramic paste onto the glass surface through high-temperature firing, resulting in a durable, opaque or translucent coating. This process produces a slit- and scratch-resistant surface ideal for architectural applications such as sunshades, facades, and privacy panels. Compared to silk-screened glass, ceramic frit glass offers superior longevity and resistance to fading.

Visual Appearance and Design Flexibility

Silk-screened glass offers vibrant color options and sharp, detailed patterns, making it ideal for intricate designs and custom branding. Ceramic frit glass provides a more durable and weather-resistant finish with a matte or textured appearance, often used for subtle, uniform looks. Your choice depends on whether you prioritize bold visual impact or longevity and consistent aesthetic performance.

Durability and Longevity Comparison

Silk-screened glass and ceramic frit glass both offer durable finishes, but ceramic frit glass generally provides superior longevity due to its baked-on ceramic enamel that resists fading, chipping, and scratching over time. Ceramic frit glass withstands harsh weather conditions and UV exposure better, maintaining its aesthetic and protective qualities for decades. Silk-screened glass, while cost-effective and visually versatile, tends to have a shorter lifespan as the printed patterns can wear away more quickly under environmental stress.

Applications in Architecture and Interior Design

Silk-screened glass offers customizable patterns and vibrant colors, making it ideal for decorative facades, partition walls, and privacy screens in both commercial and residential architecture. Ceramic frit glass provides durability and UV resistance, commonly used for sunshading systems, spandrel panels, and energy-efficient curtain walls. Both materials enhance aesthetic appeal and functional performance in interior design, with ceramic frit glass favored for its longevity and silk-screened glass for detailed graphic expression.

Performance: UV Resistance and Fading

Silk-screened glass offers moderate UV resistance but may experience fading over time due to exposure to sunlight and weather conditions. Ceramic frit glass provides superior UV resistance with durable, baked-in coloring that prevents fading and maintains aesthetic integrity even under prolonged solar exposure. This makes ceramic frit glass a preferred choice for architectural applications requiring long-lasting visual performance and protection against UV degradation.

Cost Considerations and Installation

Silk-screened glass generally incurs lower material costs compared to ceramic frit glass, making it a budget-friendly option for decorative and privacy applications. Installation of silk-screened glass is straightforward and quicker due to its lighter surface treatment, reducing labor expenses and project timelines. Your choice may depend on balancing initial costs and desired durability, as ceramic frit glass offers enhanced longevity and weather resistance despite higher installation complexity.

Environmental Impact and Sustainability

Silk-screened glass typically uses organic inks that can release volatile organic compounds (VOCs) during production, whereas ceramic frit glass involves infusing inorganic ceramic materials that are more environmentally stable and durable. Ceramic frit glass offers greater sustainability due to its longer lifespan and recyclability without significant degradation of properties. Your choice can reduce environmental impact by favoring ceramic frit glass, which contributes to lower emissions and less chemical waste throughout its lifecycle.

Choosing Between Silk-Screened and Ceramic Frit Glass

Choosing between silk-screened and ceramic frit glass depends on your specific design and durability needs; silk-screened glass offers vibrant, customizable patterns through ink application, ideal for aesthetic-focused projects. Ceramic frit glass features a durable, baked-on ceramic coating that withstands weathering and wear, providing long-lasting opacity and privacy. Your selection should balance visual appeal with performance requirements to ensure optimal functionality and style.

silk-screened glass vs ceramic frit glass Infographic

libmatt.com

libmatt.com