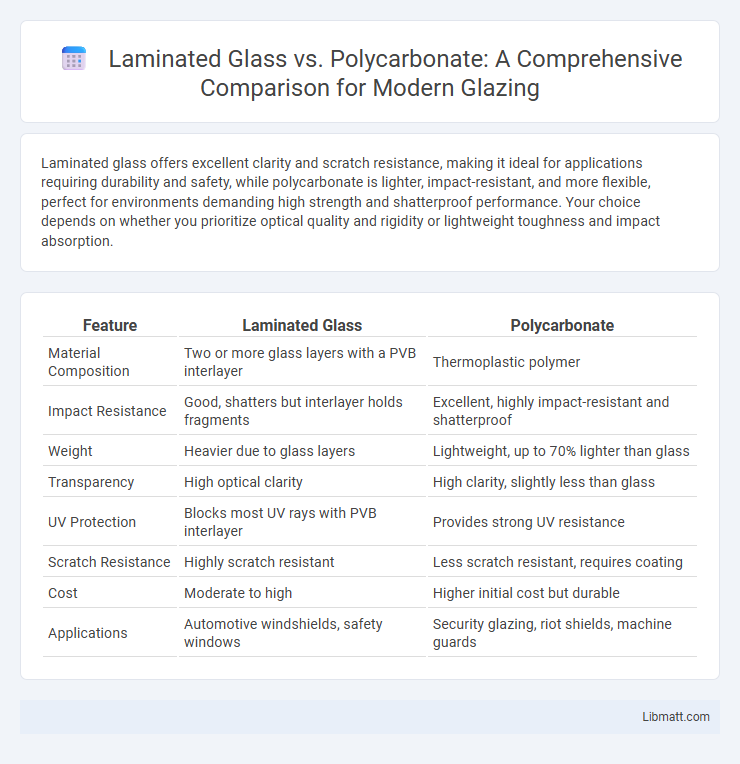

Laminated glass offers excellent clarity and scratch resistance, making it ideal for applications requiring durability and safety, while polycarbonate is lighter, impact-resistant, and more flexible, perfect for environments demanding high strength and shatterproof performance. Your choice depends on whether you prioritize optical quality and rigidity or lightweight toughness and impact absorption.

Table of Comparison

| Feature | Laminated Glass | Polycarbonate |

|---|---|---|

| Material Composition | Two or more glass layers with a PVB interlayer | Thermoplastic polymer |

| Impact Resistance | Good, shatters but interlayer holds fragments | Excellent, highly impact-resistant and shatterproof |

| Weight | Heavier due to glass layers | Lightweight, up to 70% lighter than glass |

| Transparency | High optical clarity | High clarity, slightly less than glass |

| UV Protection | Blocks most UV rays with PVB interlayer | Provides strong UV resistance |

| Scratch Resistance | Highly scratch resistant | Less scratch resistant, requires coating |

| Cost | Moderate to high | Higher initial cost but durable |

| Applications | Automotive windshields, safety windows | Security glazing, riot shields, machine guards |

Introduction to Laminated Glass and Polycarbonate

Laminated glass consists of two or more glass layers bonded by an interlayer, delivering enhanced safety and sound insulation. Polycarbonate is a lightweight, impact-resistant thermoplastic known for its superior durability and UV protection. Both materials serve critical roles in construction and automotive industries, offering distinct advantages based on application requirements.

Composition and Manufacturing Processes

Laminated glass consists of two or more glass layers bonded with an interlayer, typically polyvinyl butyral (PVB), through heat and pressure, offering enhanced safety and sound insulation. Polycarbonate is a transparent thermoplastic polymer produced by polymerizing bisphenol A with phosgene, known for its lightweight and high impact resistance. The manufacturing process for laminated glass involves autoclaving under heat and pressure, whereas polycarbonate is formed through extrusion or injection molding, allowing for versatile shapes and high durability.

Strength and Impact Resistance Comparison

Laminated glass offers high rigidity and shatter resistance due to its multi-layer construction with a polymer interlayer, making it effective against impacts while maintaining transparency. Polycarbonate surpasses laminated glass in impact resistance, being up to 250 times stronger than ordinary glass and nearly unbreakable, often used in security and safety applications. While laminated glass provides excellent structural strength and prevents glass shards from dispersing upon impact, polycarbonate delivers superior toughness and flexibility, absorbing impacts without cracking.

Safety and Security Features

Laminated glass offers enhanced safety through its inner interlayer that holds shards together upon impact, reducing the risk of injury and preventing easy penetration. Polycarbonate excels in security due to its high impact resistance, making it virtually unbreakable and ideal for riot shields and bulletproof applications. Both materials provide superior protection, but polycarbonate is generally preferred for scenarios requiring maximum resistance to forced entry or ballistic threats.

Optical Clarity and Aesthetic Differences

Laminated glass offers superior optical clarity with minimal distortion, providing a crystal-clear view that maintains the aesthetic appeal of architectural designs. Polycarbonate, while impact-resistant and lightweight, often exhibits slight haze and reduced transparency compared to laminated glass, which can affect visual sharpness. The choice between laminated glass and polycarbonate significantly impacts both the clarity and overall aesthetic quality of windows and facades in commercial and residential applications.

Durability and Longevity

Laminated glass offers excellent durability with a resilient interlayer that holds shards in place upon impact, extending its lifespan in safety applications. Polycarbonate outperforms in impact resistance and shatterproof qualities, making it highly durable under extreme conditions but may be prone to scratching and discoloration over time. Both materials provide long-lasting protection, yet polycarbonate often requires UV coatings to maintain clarity and longevity compared to laminated glass's inherent weather resistance.

Weight and Handling Characteristics

Laminated glass is significantly heavier than polycarbonate, often weighing up to six times more per square foot, which affects ease of handling and installation. Polycarbonate's lightweight nature improves maneuverability and reduces transportation costs, making it ideal for applications requiring frequent handling or retrofitting. Despite its weight, laminated glass offers superior rigidity and sound insulation, whereas polycarbonate provides enhanced impact resistance with substantial weight savings.

Cost Analysis and Affordability

Laminated glass generally presents a higher initial cost compared to polycarbonate, primarily due to its manufacturing process and material composition. Polycarbonate offers greater affordability with lower upfront expenses and reduced installation costs, making it a cost-effective choice for large-scale or impact-resistant applications. Long-term cost analysis favors polycarbonate for projects requiring durability and maintenance savings, despite laminated glass providing superior optical clarity and enhanced safety features.

Common Applications in Architecture and Industry

Laminated glass is widely used in architectural applications such as skylights, facades, and safety windows due to its impact resistance and ability to hold shards together upon breakage, enhancing building security and occupant safety. Polycarbonate is favored in industrial settings for machine guards, greenhouse panels, and protective barriers because of its superior toughness, lightweight properties, and high resistance to impact and harsh environmental conditions. Both materials contribute to energy efficiency and safety standards, with laminated glass offering excellent sound insulation and UV protection, while polycarbonate provides flexibility and durability in demanding environments.

Environmental Impact and Recyclability

Laminated glass is made primarily from glass and a plastic interlayer, making it partially recyclable though the separation process can be challenging and energy-intensive. Polycarbonate is a durable plastic that poses greater environmental concerns due to limited recyclability and potential microplastic pollution during disposal. You can reduce environmental impact by choosing laminated glass for applications prioritizing recyclability and considering polycarbonate only where high impact resistance is essential.

laminated glass vs polycarbonate Infographic

libmatt.com

libmatt.com