Lead glass contains lead oxide, giving it higher density, brilliance, and refractive index, ideal for decorative items and optical lenses, while soda lime glass, made primarily of silica, soda ash, and lime, is more common, cost-effective, and used in everyday windows and bottles. Your choice depends on whether you prioritize optical clarity and weight or durability and affordability.

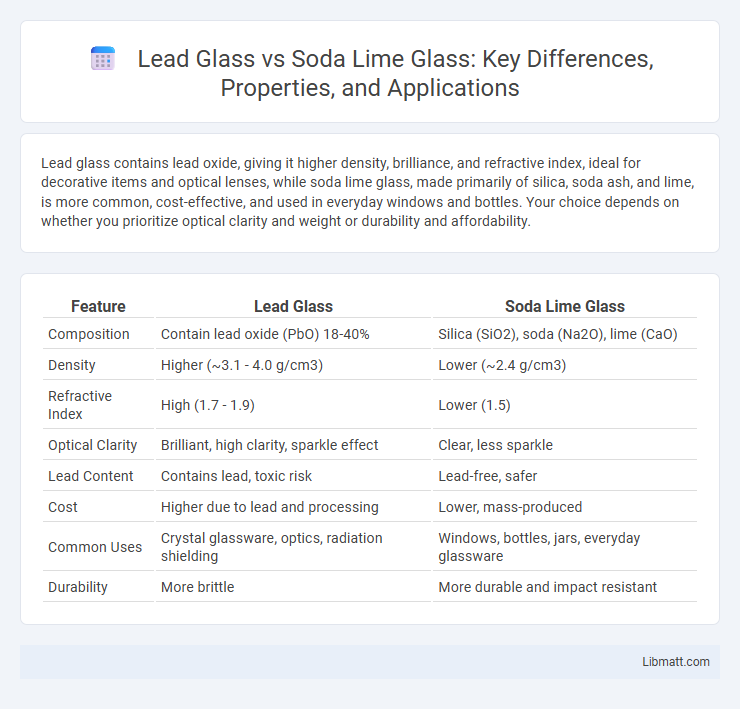

Table of Comparison

| Feature | Lead Glass | Soda Lime Glass |

|---|---|---|

| Composition | Contain lead oxide (PbO) 18-40% | Silica (SiO2), soda (Na2O), lime (CaO) |

| Density | Higher (~3.1 - 4.0 g/cm3) | Lower (~2.4 g/cm3) |

| Refractive Index | High (1.7 - 1.9) | Lower (1.5) |

| Optical Clarity | Brilliant, high clarity, sparkle effect | Clear, less sparkle |

| Lead Content | Contains lead, toxic risk | Lead-free, safer |

| Cost | Higher due to lead and processing | Lower, mass-produced |

| Common Uses | Crystal glassware, optics, radiation shielding | Windows, bottles, jars, everyday glassware |

| Durability | More brittle | More durable and impact resistant |

Introduction to Lead Glass and Soda Lime Glass

Lead glass contains a high percentage of lead oxide, typically between 18% and 40%, which enhances its refractive index and brilliance compared to soda lime glass. Soda lime glass, the most common glass type, consists mainly of silica, sodium oxide, and calcium oxide, offering cost-effective durability and versatility. You can choose lead glass for luxury items needing sparkle and weight, while soda lime glass suits everyday applications requiring strength and affordability.

Chemical Composition Differences

Lead glass contains a high percentage of lead oxide (PbO), typically ranging from 18% to 40%, which increases its refractive index and density, enhancing brilliance and clarity. Soda lime glass primarily consists of silica (SiO2), soda (Na2O), and lime (CaO), with lead oxide virtually absent, resulting in a more affordable and chemically stable material but with lower optical properties. The distinct chemical compositions of lead glass and soda lime glass directly influence their physical characteristics, including weight, clarity, and resistance to environmental factors.

Optical Properties Comparison

Lead glass exhibits higher refractive index and greater light dispersion than soda lime glass, resulting in superior brilliance and clarity. Soda lime glass, while more chemically stable and cost-effective, has lower optical clarity and transmittance, making it less ideal for precision optics. The increased density in lead glass enhances its ability to bend and refract light, providing distinct advantages in lenses and decorative glassware.

Density and Weight Characteristics

Lead glass exhibits a higher density, typically around 3.1 to 3.4 g/cm3, due to its lead oxide content, making it significantly heavier than soda lime glass, which has a density of about 2.4 to 2.6 g/cm3. This increased density enhances lead glass's weight characteristics, contributing to its use in applications requiring greater mass and optical clarity, such as in fine glassware and radiation shielding. Soda lime glass, being lighter and less dense, is preferred for everyday uses like windows and bottles where lower weight is advantageous.

Durability and Resistance to Damage

Lead glass offers enhanced durability and superior resistance to damage compared to soda lime glass due to its higher density and lead content, which makes it less prone to chipping and cracking. Soda lime glass, while more economical and widely used, is more susceptible to scratches and breakage under impact. When choosing materials for applications requiring long-lasting performance, lead glass can better protect your investment through improved resilience.

Applications and Common Uses

Lead glass is widely used in optical lenses, radiation shielding, and decorative items due to its high refractive index and density, enhancing clarity and protection. Soda lime glass is predominantly employed in windows, bottles, and everyday containers because of its cost-effectiveness and chemical durability. The choice between lead glass and soda lime glass depends on application requirements such as optical performance, weight, and safety considerations.

Health and Safety Considerations

Lead glass contains lead oxide, which can pose health risks if broken or improperly handled, as lead exposure may cause neurological and developmental issues. Soda lime glass is generally safer for everyday use due to its composition of silica, soda, and lime, which are non-toxic and less hazardous when shattered. Proper disposal and handling of lead glass are essential to prevent lead contamination, while soda lime glass is widely recycled with minimal health concerns.

Environmental Impact and Recycling

Lead glass contains toxic lead oxide that poses significant environmental hazards during manufacturing and disposal, complicating recycling processes due to its heavy metal content. Soda lime glass, composed primarily of silica, soda, and lime, is more environmentally friendly as it can be recycled more easily and with less energy, reducing landfill waste and pollution. Your choice of soda lime glass supports sustainable practices by minimizing toxic emissions and promoting efficient recycling infrastructure.

Cost and Market Availability

Lead glass typically costs more than soda lime glass due to its higher lead oxide content and specialized manufacturing process. Soda lime glass dominates the market with widespread availability and lower prices, making it the preferred choice for everyday applications. Your decision may hinge on budget constraints and the necessity for lead glass's superior optical properties.

Choosing the Right Glass for Your Needs

Lead glass offers superior clarity, brilliance, and higher refractive index compared to soda lime glass, making it ideal for decorative items and optical applications. Soda lime glass is more affordable, durable, and suitable for everyday use such as windows and bottles. When selecting glass for your needs, consider the importance of optical quality versus cost and durability requirements.

lead glass vs soda lime glass Infographic

libmatt.com

libmatt.com