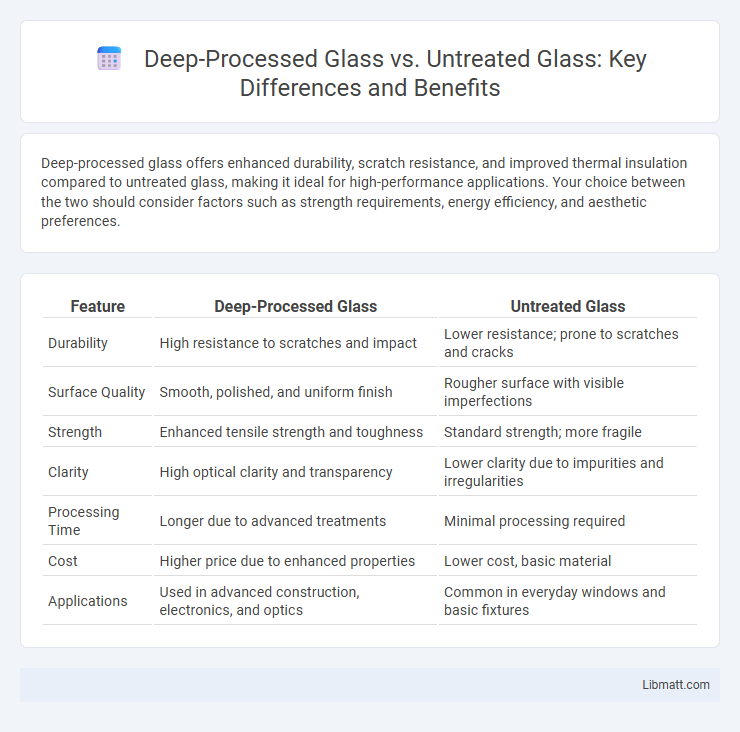

Deep-processed glass offers enhanced durability, scratch resistance, and improved thermal insulation compared to untreated glass, making it ideal for high-performance applications. Your choice between the two should consider factors such as strength requirements, energy efficiency, and aesthetic preferences.

Table of Comparison

| Feature | Deep-Processed Glass | Untreated Glass |

|---|---|---|

| Durability | High resistance to scratches and impact | Lower resistance; prone to scratches and cracks |

| Surface Quality | Smooth, polished, and uniform finish | Rougher surface with visible imperfections |

| Strength | Enhanced tensile strength and toughness | Standard strength; more fragile |

| Clarity | High optical clarity and transparency | Lower clarity due to impurities and irregularities |

| Processing Time | Longer due to advanced treatments | Minimal processing required |

| Cost | Higher price due to enhanced properties | Lower cost, basic material |

| Applications | Used in advanced construction, electronics, and optics | Common in everyday windows and basic fixtures |

Introduction to Deep-Processed and Untreated Glass

Deep-processed glass undergoes treatments such as tempering, coating, or laminating to enhance durability, safety, and optical properties, making it ideal for automotive, architectural, and electronic applications. Untreated glass, in its raw form, lacks these enhancements and is more prone to breakage, scratches, and reduced performance under stress or environmental factors. Understanding the differences in strength, clarity, and resistance between deep-processed and untreated glass helps you choose the right material for your specific needs.

Manufacturing Processes: Deep-Processed vs Untreated Glass

Deep-processed glass undergoes advanced manufacturing techniques such as chemical strengthening, precision cutting, polishing, and coating applications to enhance durability, optical clarity, and surface smoothness. Untreated glass is typically produced through basic melting and forming processes, lacking additional modifications that improve performance or aesthetic qualities. Choosing deep-processed glass can significantly impact your project's quality by providing superior resistance to scratches, thermal stress, and enhanced visual properties compared to untreated glass.

Physical and Mechanical Properties Comparison

Deep-processed glass exhibits enhanced physical and mechanical properties compared to untreated glass, including increased hardness, improved scratch resistance, and higher tensile strength. The deep processing techniques such as chemical tempering and ion exchange create a compressive stress layer on the glass surface, significantly boosting its durability and resistance to impact. Untreated glass remains more susceptible to cracking, chipping, and surface damage due to its lower surface strength and absence of reinforcement.

Aesthetic Differences and Design Flexibility

Deep-processed glass offers enhanced aesthetic appeal through customized textures, colors, and finishes that are impossible to achieve with untreated glass, providing designers with a broader palette for creative expression. Its ability to be molded, laminated, or coated allows for intricate patterns and unique visual effects that enhance architectural and interior design projects. Untreated glass, while clear and simple, limits design flexibility by maintaining a plain appearance and lacking the surface treatments essential for bespoke visual statements.

Durability and Safety Standards

Deep-processed glass features enhanced durability due to treatments like tempering or lamination, which increase resistance to impact and thermal stress compared to untreated glass. It meets rigorous safety standards such as ANSI Z97.1 and EN 12150, ensuring it shatters into small, less harmful pieces or remains intact when fractured. Untreated glass lacks these reinforcements and safety certifications, posing higher risks of breakage and injury under similar conditions.

Energy Efficiency and Insulation Performance

Deep-processed glass significantly enhances energy efficiency by incorporating multiple coatings and gas fills that reduce heat transfer, maintaining consistent indoor temperatures and lowering energy costs. Untreated glass lacks these advanced features, resulting in higher thermal conductivity and inferior insulation performance. Your choice of deep-processed glass improves overall building insulation, reduces reliance on heating and cooling systems, and promotes sustainable energy use.

Applications in Modern Architecture

Deep-processed glass offers superior strength, thermal insulation, and customizable aesthetics compared to untreated glass, making it ideal for skyscraper facades, green buildings, and complex curtain walls. Its enhanced durability and energy efficiency contribute to sustainable designs and reduce maintenance costs. Untreated glass, while more affordable, lacks these advanced features, limiting its use primarily to interior partitions and low-stress applications.

Cost Analysis: Investment and Long-Term Value

Deep-processed glass typically requires a higher initial investment due to advanced manufacturing and finishing techniques, but it offers superior durability, energy efficiency, and reduced maintenance costs that enhance long-term value. Untreated glass is less expensive upfront but tends to degrade faster, leading to higher replacement and upkeep expenses over time. You can optimize your budget by balancing the immediate cost with the extended benefits of deep-processed glass in your project.

Environmental Impact and Sustainability Considerations

Deep-processed glass involves chemical and thermal treatments that enhance durability but often require significant energy consumption, increasing its environmental footprint compared to untreated glass. Untreated glass, while less durable, is more sustainable due to lower processing energy and easier recyclability without the introduction of complex coatings or treatments. Considering lifecycle assessments, untreated glass typically results in reduced carbon emissions and energy use, making it a greener choice for eco-conscious applications.

Choosing the Right Glass: Key Factors to Consider

Deep-processed glass offers enhanced durability, scratch resistance, and improved optical clarity compared to untreated glass, making it ideal for applications requiring long-term performance and aesthetic appeal. Key factors to consider when choosing between deep-processed and untreated glass include the specific environmental conditions, required strength, and maintenance demands. Cost-effectiveness and functional benefits should be weighed carefully to ensure the selected glass meets both practical and budgetary needs.

Deep-processed glass vs untreated glass Infographic

libmatt.com

libmatt.com