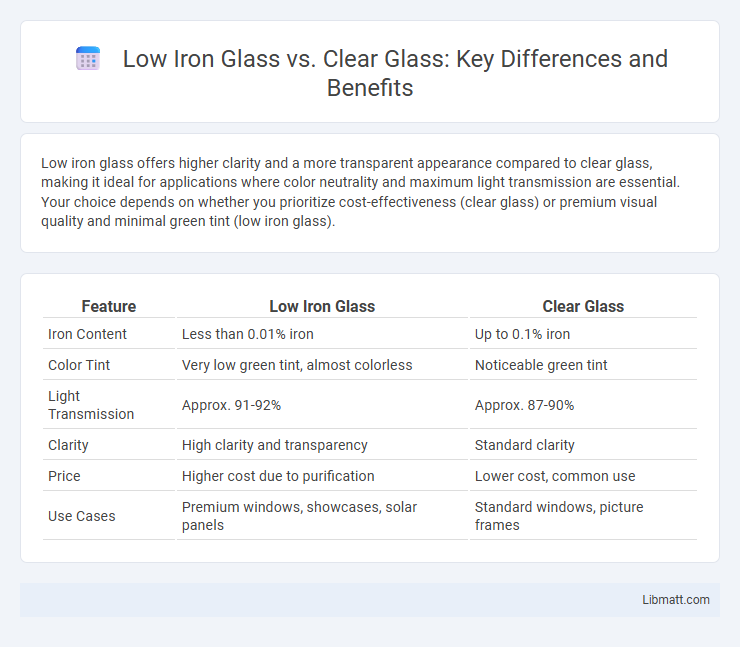

Low iron glass offers higher clarity and a more transparent appearance compared to clear glass, making it ideal for applications where color neutrality and maximum light transmission are essential. Your choice depends on whether you prioritize cost-effectiveness (clear glass) or premium visual quality and minimal green tint (low iron glass).

Table of Comparison

| Feature | Low Iron Glass | Clear Glass |

|---|---|---|

| Iron Content | Less than 0.01% iron | Up to 0.1% iron |

| Color Tint | Very low green tint, almost colorless | Noticeable green tint |

| Light Transmission | Approx. 91-92% | Approx. 87-90% |

| Clarity | High clarity and transparency | Standard clarity |

| Price | Higher cost due to purification | Lower cost, common use |

| Use Cases | Premium windows, showcases, solar panels | Standard windows, picture frames |

Introduction to Low Iron Glass and Clear Glass

Low iron glass contains significantly reduced iron oxide, resulting in higher light transmission and enhanced clarity compared to standard clear glass. Clear glass, with its natural iron content, often exhibits a greenish tint that can slightly distort colors and reduce transparency. Your choice between low iron and clear glass impacts aesthetic appeal and optical performance in architectural and design applications.

What Is Low Iron Glass?

Low iron glass is a type of glass specially manufactured to have reduced iron content, resulting in higher transparency and minimal greenish tint compared to standard clear glass. This glass offers superior light transmission, typically around 91-92%, making it ideal for applications requiring enhanced clarity, such as display cases, storefronts, and solar panels. Due to its purity, low iron glass enhances color accuracy and visual appeal, distinguishing it from conventional clear glass with higher iron levels.

What Is Clear Glass?

Clear glass is a basic, transparent material made primarily from silica sand, soda ash, and limestone, allowing maximum light transmission without color distortion. It typically has a higher iron content, which gives it a slightly greenish tint, especially noticeable at the edges or in thicker panels. Unlike low iron glass, clear glass offers less clarity and color neutrality, making it less ideal for applications requiring true color representation and maximum brightness.

Key Differences Between Low Iron and Clear Glass

Low iron glass contains significantly reduced iron content, resulting in higher clarity and greater light transmission compared to standard clear glass, which often has a slight green tint due to iron impurities. This enhanced transparency makes low iron glass ideal for applications requiring true color representation, such as display cases and solar panels. Your choice between low iron and clear glass depends on the necessity for visual accuracy and performance in natural light conditions.

Light Transmission in Low Iron vs. Clear Glass

Low iron glass offers higher light transmission compared to clear glass, typically allowing up to 91% or more of natural light to pass through, whereas standard clear glass transmits around 83-85%. This increased clarity and brightness in low iron glass reduce the greenish tint found in clear glass, making it ideal for applications requiring maximum transparency and color accuracy. Enhanced light transmission in low iron glass improves energy efficiency and visual comfort in architectural and automotive uses.

Color and Visual Clarity Comparison

Low iron glass exhibits enhanced color neutrality and superior visual clarity compared to standard clear glass, reducing the greenish tint caused by iron impurities. This results in a brighter, more transparent appearance ideal for architectural applications requiring true color representation. The improved optical quality of low iron glass enhances natural light transmission and visual aesthetics in both residential and commercial settings.

Applications of Low Iron Glass

Low iron glass is widely used in applications requiring maximum light transmission and clarity, such as in solar panels, aquarium tanks, and museum displays, where color neutrality and transparency are critical. Its reduced iron content minimizes the greenish tint typical of standard clear glass, making it ideal for architectural glazing, skylights, and high-end storefronts to enhance aesthetic appeal and visual accuracy. You will benefit from low iron glass in projects demanding superior optical performance and natural light enhancement.

Common Uses of Clear Glass

Clear glass, known for its natural transparency and affordability, is commonly used in windows, picture frames, and glassware where color neutrality and clarity are essential. It is widely utilized in residential and commercial buildings for standard glazing applications, providing visibility without distortion. Clear glass also serves as a base for decorative elements and is favored in interior design for shelving and tabletops due to its simple, clean appearance.

Cost Considerations: Low Iron Glass vs. Clear Glass

Low iron glass typically costs 20-30% more than clear glass due to its higher purity and reduced iron content, which enhances clarity and light transmission. The premium price reflects manufacturing complexity and benefits such as improved aesthetics in architectural applications and superior performance in solar panels. Clear glass remains a budget-friendly option suitable for standard windows where color distortion and light absorption are less critical.

Choosing the Right Glass for Your Project

Low iron glass offers superior clarity and enhanced light transmission compared to standard clear glass, making it ideal for projects requiring maximum visibility and brightness. Clear glass contains higher iron content, resulting in a greenish tint that can affect the color accuracy and overall aesthetic. Your choice should prioritize the visual impact and performance needs of your project, with low iron glass preferred for frameless designs, museum displays, and high-end architectural applications.

low iron glass vs clear glass Infographic

libmatt.com

libmatt.com