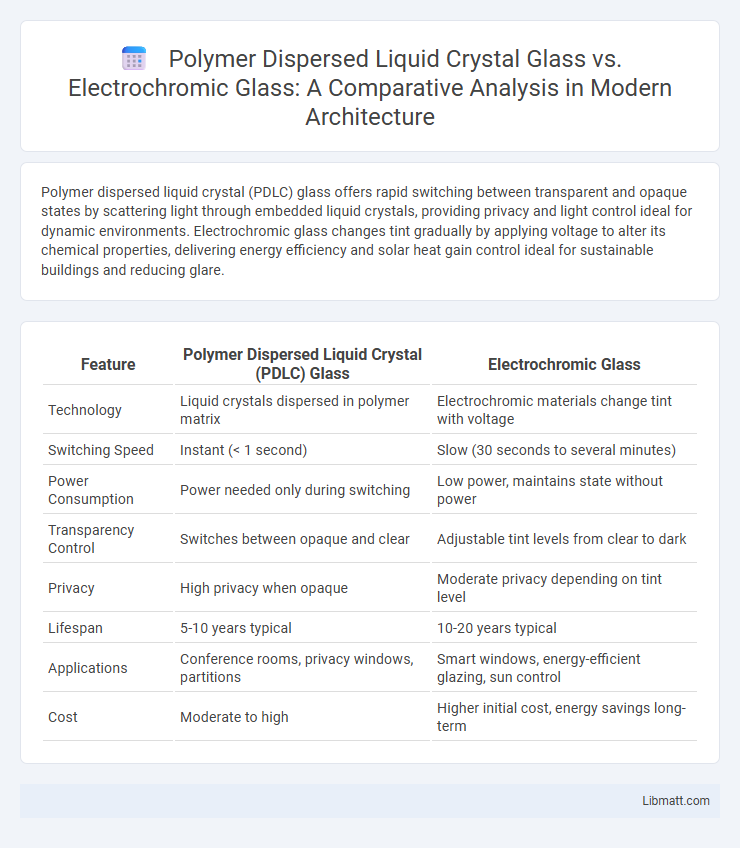

Polymer dispersed liquid crystal (PDLC) glass offers rapid switching between transparent and opaque states by scattering light through embedded liquid crystals, providing privacy and light control ideal for dynamic environments. Electrochromic glass changes tint gradually by applying voltage to alter its chemical properties, delivering energy efficiency and solar heat gain control ideal for sustainable buildings and reducing glare.

Table of Comparison

| Feature | Polymer Dispersed Liquid Crystal (PDLC) Glass | Electrochromic Glass |

|---|---|---|

| Technology | Liquid crystals dispersed in polymer matrix | Electrochromic materials change tint with voltage |

| Switching Speed | Instant (< 1 second) | Slow (30 seconds to several minutes) |

| Power Consumption | Power needed only during switching | Low power, maintains state without power |

| Transparency Control | Switches between opaque and clear | Adjustable tint levels from clear to dark |

| Privacy | High privacy when opaque | Moderate privacy depending on tint level |

| Lifespan | 5-10 years typical | 10-20 years typical |

| Applications | Conference rooms, privacy windows, partitions | Smart windows, energy-efficient glazing, sun control |

| Cost | Moderate to high | Higher initial cost, energy savings long-term |

Introduction to Smart Glass Technologies

Smart glass technologies enhance energy efficiency and privacy by dynamically controlling light transmission through materials like polymer dispersed liquid crystal (PDLC) glass and electrochromic glass. PDLC glass uses liquid crystal droplets dispersed in a polymer matrix that switch between opaque and transparent states with applied electric voltage, providing rapid light modulation ideal for privacy applications. Electrochromic glass alters tint through an electrochemical process that changes the oxidation state of its coating, enabling gradual control of solar heat and glare, which optimizes building energy management and occupant comfort.

Overview of Polymer Dispersed Liquid Crystal (PDLC) Glass

Polymer Dispersed Liquid Crystal (PDLC) glass consists of liquid crystal droplets embedded in a polymer matrix, enabling dynamic opacity control when an electric current aligns the liquid crystals. PDLC glass switches from opaque to transparent instantly, providing privacy without blocking light, making it ideal for offices, healthcare, and automotive applications. Compared to electrochromic glass, which changes tint gradually through a chemical reaction, PDLC offers faster response times and greater flexibility in light diffusion.

Understanding Electrochromic Glass Technology

Electrochromic glass technology utilizes a thin film that changes its opacity or color when an electrical voltage is applied, enabling dynamic control of light and heat transmission. Compared to polymer dispersed liquid crystal (PDLC) glass, which switches between transparent and opaque states using electrical fields to scatter light, electrochromic glass offers gradual tinting for energy efficiency and glare reduction. This technology enhances building performance by reducing HVAC loads and improving occupant comfort through precise modulation of solar heat gain and daylight.

Mechanisms Behind Light Control in PDLC and Electrochromic Glass

Polymer dispersed liquid crystal (PDLC) glass controls light by using microscopic liquid crystal droplets dispersed in a polymer matrix that align under an electric field, switching the glass from opaque to transparent by modulating light scattering. Electrochromic glass relies on reversible redox reactions in electrochromic materials that change the glass tint by altering its optical absorption when voltage is applied. The PDLC mechanism offers rapid switching times typically in milliseconds, while electrochromic glass exhibits slower transitions ranging from seconds to minutes, favoring energy-efficient light and heat management.

Comparing Energy Efficiency: PDLC vs Electrochromic Glass

Polymer dispersed liquid crystal (PDLC) glass provides rapid light modulation by scattering or transmitting light, which allows for instant privacy but often consumes more energy during operation compared to electrochromic glass, which changes tint gradually through an electrochemical reaction and maintains state without continuous power. Electrochromic glass offers superior energy efficiency by reducing solar heat gain and minimizing HVAC loads, making it ideal for long-term energy savings in buildings. Your choice depends on whether immediate switchability or sustained energy efficiency is the primary priority for your application.

Visual Clarity and Transparency Differences

Polymer dispersed liquid crystal (PDLC) glass typically offers variable transparency by scattering light in its opaque state, resulting in reduced visual clarity compared to electrochromic glass, which provides uniform tinting without compromising sharpness. Electrochromic glass adjusts its visible light transmittance smoothly, maintaining high transparency and clear visibility even when darkened. Your choice depends on whether you prioritize rapid privacy switching with PDLC or enhanced optical clarity with electrochromic technology.

Response Time and User Control Capabilities

Polymer dispersed liquid crystal (PDLC) glass typically exhibits faster response times, switching between opaque and transparent states in milliseconds, whereas electrochromic glass changes gradually over several minutes. PDLC glass allows binary user control, toggling between clear and frosted, while electrochromic glass offers variable tint options, enabling more nuanced light and heat management. The rapid switching of PDLC suits dynamic privacy needs, whereas electrochromic's adjustable shading enhances energy efficiency and user comfort.

Installation and Maintenance Considerations

Polymer dispersed liquid crystal (PDLC) glass offers straightforward installation with a simple wiring setup for electrical control, making it suitable for retrofitting existing windows without extensive structural changes. Electrochromic glass requires a more complex installation process due to the integration of multiple layers and control systems, often necessitating specialized professional services and potentially longer downtime. Maintenance for PDLC glass is minimal, primarily involving periodic electrical checks, whereas electrochromic glass may require more frequent calibration and replacement of electronic components to maintain optimal performance over time.

Cost Analysis: PDLC Glass vs Electrochromic Glass

Polymer dispersed liquid crystal (PDLC) glass typically incurs higher upfront costs due to its complex manufacturing process and advanced liquid crystal technology, whereas electrochromic glass benefits from more established production methods resulting in lower initial expenses. Operational costs for electrochromic glass tend to be reduced as it requires less power to maintain its state compared to the continuous energy consumption of PDLC glass's opaque mode. Maintenance and lifecycle expenses favor electrochromic technology due to its longer durability and fewer replacement needs, making it a cost-effective solution in long-term applications.

Ideal Applications and Use Cases for Each Technology

Polymer dispersed liquid crystal (PDLC) glass excels in applications requiring instant privacy control, such as conference rooms, healthcare facilities, and residential windows, where rapid switching between transparent and opaque states enhances privacy and light management. Electrochromic glass is ideal for energy-efficient buildings, automotive windows, and smart eyewear, providing gradual tint adjustment to optimize glare reduction and thermal regulation while minimizing energy consumption. Both technologies suit dynamic environments but differ in switching speed, power use, and cost, influencing their selection based on specific functional and economic requirements.

polymer dispersed liquid crystal glass vs electrochromic glass Infographic

libmatt.com

libmatt.com