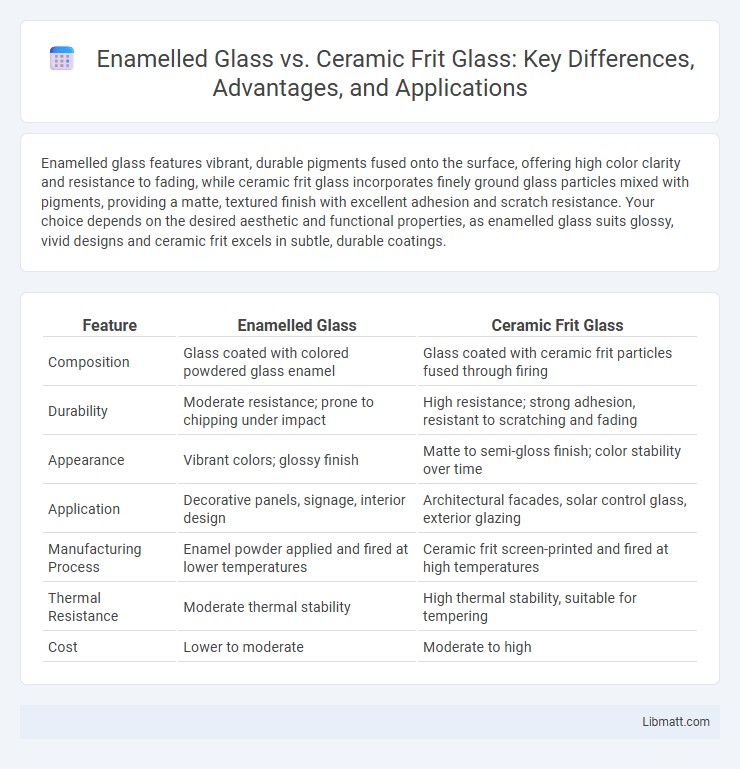

Enamelled glass features vibrant, durable pigments fused onto the surface, offering high color clarity and resistance to fading, while ceramic frit glass incorporates finely ground glass particles mixed with pigments, providing a matte, textured finish with excellent adhesion and scratch resistance. Your choice depends on the desired aesthetic and functional properties, as enamelled glass suits glossy, vivid designs and ceramic frit excels in subtle, durable coatings.

Table of Comparison

| Feature | Enamelled Glass | Ceramic Frit Glass |

|---|---|---|

| Composition | Glass coated with colored powdered glass enamel | Glass coated with ceramic frit particles fused through firing |

| Durability | Moderate resistance; prone to chipping under impact | High resistance; strong adhesion, resistant to scratching and fading |

| Appearance | Vibrant colors; glossy finish | Matte to semi-gloss finish; color stability over time |

| Application | Decorative panels, signage, interior design | Architectural facades, solar control glass, exterior glazing |

| Manufacturing Process | Enamel powder applied and fired at lower temperatures | Ceramic frit screen-printed and fired at high temperatures |

| Thermal Resistance | Moderate thermal stability | High thermal stability, suitable for tempering |

| Cost | Lower to moderate | Moderate to high |

Introduction to Enamelled Glass and Ceramic Frit Glass

Enamelled glass features a layer of powdered glass fused onto its surface through high-temperature firing, resulting in vibrant, durable colors and intricate designs ideal for decorative and architectural applications. Ceramic frit glass, composed of finely ground ceramic particles embedded within or on the glass surface, offers enhanced durability, chemical resistance, and matte or textured finishes suitable for industrial and artistic uses. Both materials provide unique aesthetic and functional properties, with enamelled glass excelling in color vibrancy and ceramic frit glass delivering superior surface resilience.

Composition and Manufacturing Processes

Enamelled glass is created by fusing powdered glass mixed with metallic oxides onto a glass substrate at high temperatures, resulting in a smooth, durable surface with vibrant colors. Ceramic frit glass involves applying a ceramic-based glass paste that is then fired to form an opaque or translucent coating with excellent weather resistance and chemical stability. Your choice depends on whether you need the glossy finish and color intensity of enamelled glass or the robust, matte texture and durability of ceramic frit coatings.

Visual Appearance and Design Flexibility

Enamelled glass offers vibrant color depth and a smooth, glossy finish that enhances intricate visual details, making it ideal for high-definition artwork and decorative applications. Ceramic frit glass provides a more matte and textured surface, allowing for subtle variegated patterns and a softer aesthetic often favored in architectural facades. Both materials excel in design flexibility, but enamelled glass supports finer resolution and sharper color contrasts, while ceramic frit glass facilitates layering effects and durability in exterior uses.

Durability and Performance Comparison

Enamelled glass offers superior chemical resistance and vibrant long-lasting colors due to its fused glass particles, making it highly durable for architectural facades. Ceramic frit glass, composed of powdered glass and pigments baked onto the surface, provides excellent weather resistance and thermal stability but may exhibit slight color fading over time. Both materials deliver robust performance, with enamelled glass excelling in scratch resistance while ceramic frit glass offers greater flexibility in design patterns and thermal properties.

Color and Pattern Retention Over Time

Enamelled glass offers superior color vibrancy but may experience gradual fading when exposed to prolonged UV radiation, whereas ceramic frit glass demonstrates exceptional durability with colors and patterns that remain stable and resistant to wear over extended periods. The high-temperature firing process of ceramic frit fuses the color pigments into the glass surface, ensuring long-lasting retention even in harsh environmental conditions. For applications requiring enduring aesthetic appeal, ceramic frit glass provides a more reliable solution in maintaining color integrity over time.

Applications in Architecture and Interior Design

Enamelled glass offers vibrant color customization and durability, making it ideal for decorative facades, glass partitions, and wall cladding in architectural and interior design projects. Ceramic frit glass provides excellent thermal performance and UV resistance, commonly used in energy-efficient building facades, sunshades, and skylights. Both materials enhance aesthetic appeal while providing functional benefits such as weather resistance and easy maintenance in modern construction and interior environments.

Environmental Impact and Sustainability

Enamelled glass involves high-temperature fusing of powdered glass to a substrate, resulting in durability but higher energy consumption during production compared to ceramic frit glass, which can be applied at lower temperatures, reducing carbon footprint. Ceramic frit glass coatings often use less hazardous materials and generate fewer emissions, contributing to improved environmental sustainability in architectural and automotive applications. The choice between enamelled and ceramic frit glass impacts resource efficiency, recyclability, and long-term environmental performance in glass manufacturing.

Cost Considerations and Budgeting

Enamelled glass generally comes at a higher cost compared to ceramic frit glass due to its more complex manufacturing process and vibrant, durable coloration. Ceramic frit glass offers a more budget-friendly option, providing satisfactory durability and aesthetic appeal for large-scale projects without compromising on quality. When budgeting, you should consider that enamelled glass may increase overall expenses but delivers superior color longevity and design precision.

Maintenance and Cleaning Requirements

Enamelled glass requires gentle cleaning with non-abrasive, pH-neutral cleaners to maintain its vibrant colors and prevent surface damage. Ceramic frit glass offers higher durability and resists scratching and staining, making it easier to clean with mild detergents and soft cloths. Your choice depends on balancing aesthetic longevity with the ease of routine maintenance in your specific environment.

Choosing the Right Option for Your Project

Enamelled glass offers vibrant, long-lasting color achieved by fusing powdered glass to a substrate at high temperatures, ideal for decorative and artistic applications requiring precision and durability. Ceramic frit glass provides a more matte, textured finish with excellent UV resistance and thermal stability, suitable for architectural facades and energy-efficient building designs. Selecting between enamelled and ceramic frit glass depends on factors such as desired aesthetic effect, exposure conditions, and project specification requirements.

enamelled glass vs ceramic frit glass Infographic

libmatt.com

libmatt.com