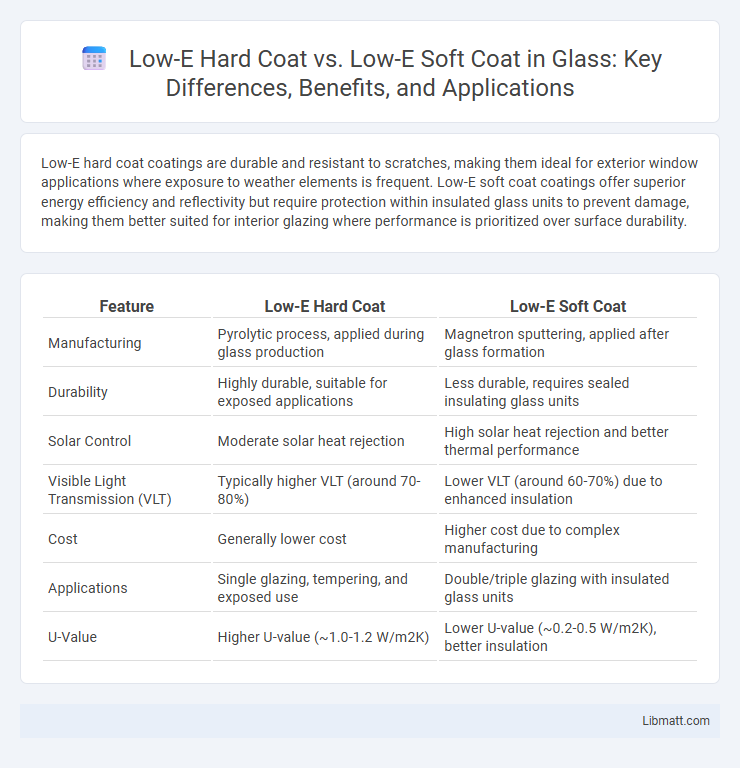

Low-E hard coat coatings are durable and resistant to scratches, making them ideal for exterior window applications where exposure to weather elements is frequent. Low-E soft coat coatings offer superior energy efficiency and reflectivity but require protection within insulated glass units to prevent damage, making them better suited for interior glazing where performance is prioritized over surface durability.

Table of Comparison

| Feature | Low-E Hard Coat | Low-E Soft Coat |

|---|---|---|

| Manufacturing | Pyrolytic process, applied during glass production | Magnetron sputtering, applied after glass formation |

| Durability | Highly durable, suitable for exposed applications | Less durable, requires sealed insulating glass units |

| Solar Control | Moderate solar heat rejection | High solar heat rejection and better thermal performance |

| Visible Light Transmission (VLT) | Typically higher VLT (around 70-80%) | Lower VLT (around 60-70%) due to enhanced insulation |

| Cost | Generally lower cost | Higher cost due to complex manufacturing |

| Applications | Single glazing, tempering, and exposed use | Double/triple glazing with insulated glass units |

| U-Value | Higher U-value (~1.0-1.2 W/m2K) | Lower U-value (~0.2-0.5 W/m2K), better insulation |

Introduction to Low-E Glass Technologies

Low-E glass technologies enhance energy efficiency by minimizing infrared and ultraviolet light transmission while maximizing visible light. Hard coat Low-E glass, created during the glass manufacturing process, offers durability and moderate solar control ideal for new construction. Soft coat Low-E glass utilizes a thin metallic coating applied in a vacuum, providing superior insulation and solar performance favored in retrofit and high-performance applications.

What is Low-E Hard Coat Glass?

Low-E hard coat glass features a durable, transparent coating applied during the glass manufacturing process, creating a hard surface that reflects infrared and ultraviolet light while allowing visible light to pass through. This type of coating is commonly used for single-pane windows and offers strong resistance to abrasion and weathering, making it suitable for exterior applications. The hard coat enhances energy efficiency by reducing heat transfer, helping to maintain indoor temperature and lower energy costs.

What is Low-E Soft Coat Glass?

Low-E soft coat glass features a microscopically thin metallic layer applied through a vacuum process, enhancing its reflective properties to reduce heat transfer and improve energy efficiency. It offers superior insulation compared to hard coat glass, providing better control over solar heat gain and visible light transmission. This type of glass is often used in high-performance windows and insulated glass units for residential and commercial buildings seeking optimal thermal performance.

Manufacturing Process Comparison

Low-E hard coat glass is created using a chemical deposition process that applies a thin, durable oxide layer while the glass is still molten, resulting in a hard, abrasion-resistant surface. Low-E soft coat glass employs a vacuum coating method to deposit multiple ultra-thin metallic layers after the glass has cooled, producing higher thermal insulation but requiring protective glazing due to its delicate surface. Your choice between hard coat and soft coat depends on factors like durability needs and energy efficiency preferences tied to their distinct manufacturing processes.

Energy Efficiency Performance

Low-E hard coat glass features a durable, abrasion-resistant coating that enhances solar heat gain reduction while maintaining high visible light transmittance, improving energy efficiency in harsh environments. Low-E soft coat glass offers superior insulating performance with a highly reflective metallic layer, significantly reducing heat transfer and lowering heating and cooling costs. Soft coat Low-E windows typically provide better overall thermal performance, especially in colder climates, due to their lower U-values and higher SHGC control.

Durability and Lifespan

Low-E hard coat glass features a durable, sputtered coating fused directly onto the glass surface, providing enhanced resistance to scratches and environmental wear, resulting in a longer lifespan often exceeding 20 years. Low-E soft coat glass, characterized by its multilayered metallic oxide coatings applied in a vacuum, delivers superior thermal performance but is more susceptible to damage and requires protective sealing, typically limiting its durability to around 15 years in standard applications. The choice between hard coat and soft coat Low-E glass depends on balancing the need for long-term durability against thermal insulation efficiency.

Cost Differences and Affordability

Low-E hard coat glass is generally more affordable due to its durable, sputtered coating applied during the glass manufacturing process, making it cost-effective for large-scale projects or budget-conscious installations. Low-E soft coat, often created using a vacuum deposition process after the glass is formed, typically demands higher manufacturing costs that may increase your overall investment but provide superior thermal performance and energy efficiency. Choosing between low-E hard coat and soft coat options depends on balancing upfront costs with long-term energy savings tailored to your specific budget and performance needs.

Applications: Best Uses for Each Type

Low-E hard coat glass is ideal for single-pane windows and storm windows due to its durability and resistance to physical wear, making it suitable for exterior applications where harsh conditions are common. Low-E soft coat glass excels in double or triple-pane insulated glazing units, offering superior thermal performance and solar control, perfect for energy-efficient residential and commercial buildings. When selecting your glass, consider hard coat for rugged outdoor exposure and soft coat for enhanced insulation and energy savings within sealed units.

Aesthetic Considerations

Low-E hard coat glass typically offers a more durable surface with a slightly less reflective appearance, making it ideal for architectural designs emphasizing robustness and subtle aesthetics. Low-E soft coat glass provides superior optical clarity and lower emissivity, resulting in enhanced visual quality and minimal color distortion, which is preferred for applications requiring pristine glass transparency. The choice between hard and soft coat impacts the overall building facade appearance, influencing light transmission, color rendition, and glare control.

Choosing the Right Low-E Coating for Your Project

Low-E hard coat coatings, also known as pyrolytic coatings, offer greater durability and resistance to scratches, making them ideal for exterior use or areas prone to wear. Low-E soft coat coatings, applied in a vacuum, provide superior solar control and higher energy efficiency but require careful handling due to their fragility. Your choice depends on project needs: hard coats suit long-lasting, exterior applications, while soft coats excel in maximizing thermal insulation and minimizing energy costs indoors.

Low-E hard coat vs Low-E soft coat Infographic

libmatt.com

libmatt.com