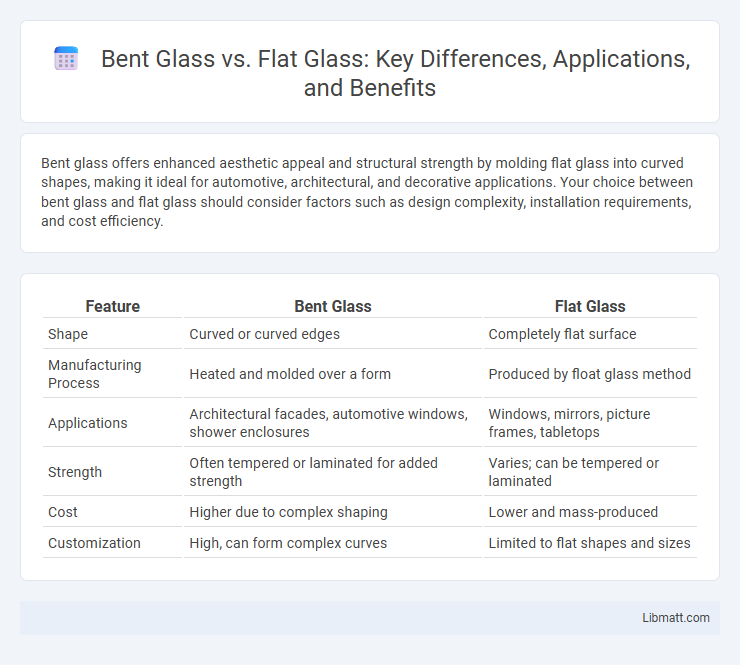

Bent glass offers enhanced aesthetic appeal and structural strength by molding flat glass into curved shapes, making it ideal for automotive, architectural, and decorative applications. Your choice between bent glass and flat glass should consider factors such as design complexity, installation requirements, and cost efficiency.

Table of Comparison

| Feature | Bent Glass | Flat Glass |

|---|---|---|

| Shape | Curved or curved edges | Completely flat surface |

| Manufacturing Process | Heated and molded over a form | Produced by float glass method |

| Applications | Architectural facades, automotive windows, shower enclosures | Windows, mirrors, picture frames, tabletops |

| Strength | Often tempered or laminated for added strength | Varies; can be tempered or laminated |

| Cost | Higher due to complex shaping | Lower and mass-produced |

| Customization | High, can form complex curves | Limited to flat shapes and sizes |

Introduction to Bent Glass and Flat Glass

Bent glass is a specially shaped glass formed by heating flat glass until it's pliable and then molding it into curved shapes, ideal for automotive windows and architectural applications requiring aerodynamic or aesthetic curves. Flat glass, also known as float glass, is produced by floating molten glass on molten metal, creating smooth, flat sheets commonly used in windows, mirrors, and furniture surfaces. Your choice between bent and flat glass depends on the specific application requirements for shape, strength, and design flexibility.

Key Differences Between Bent Glass and Flat Glass

Bent glass is curved through heat treatment to achieve specific shapes, enhancing structural and aesthetic applications, while flat glass remains planar and is commonly used for windows and mirrors. The bending process alters the glass's mechanical properties, increasing strength and resistance to thermal stress compared to flat glass. Flat glass offers uniform thickness and ease of cutting, whereas bent glass provides versatility in architectural designs and automotive components due to its customizable curvature.

Manufacturing Processes: Bent vs Flat Glass

Bent glass is manufactured through a process of heating flat glass to a pliable temperature, then shaping it using molds or gravity to achieve curved forms, enabling applications in automotive windshields, architecture, and furniture. Flat glass production involves melting raw materials at high temperatures followed by controlled cooling on a molten tin bath in the float glass process, resulting in uniform thickness and surface quality ideal for windows, mirrors, and screens. The key difference lies in bending methods after initial flat formation, with bent glass requiring precise thermal control to maintain structural integrity and optical clarity.

Strength and Durability Comparison

Bent glass exhibits enhanced strength and durability compared to flat glass due to the tempering process involved in its shaping, which increases resistance to impact and thermal stress. Its curved structure distributes mechanical forces more evenly, reducing the likelihood of cracks or breakage under pressure. If your project demands superior resilience and longevity, choosing bent glass can significantly improve performance over traditional flat glass.

Aesthetic Appeal and Design Flexibility

Bent glass offers enhanced aesthetic appeal through its smooth curves and contours, enabling architects to create dynamic, flowing designs that flat glass cannot achieve. The design flexibility of bent glass allows for customization in shapes and sizes, making it ideal for modern facades, skylights, and innovative interior applications. Flat glass, while versatile and cost-effective, lacks the three-dimensional form that adds depth and visual interest to contemporary architectural projects.

Applications in Architecture and Interior Design

Bent glass enhances architectural and interior design by enabling the creation of curved facades, skylights, and partition walls that offer aesthetic fluidity and improved structural performance. Flat glass is widely used for windows, doors, and curtain walls where uniformity, ease of installation, and cost-efficiency are prioritized. The choice between bent and flat glass depends on design complexity, desired visual impact, and functional requirements within modern building projects.

Cost Considerations and Budget Impact

Bent glass typically incurs higher costs than flat glass due to the additional manufacturing processes like heating and shaping, which require specialized equipment and increased labor. Your budget impact should account for these premium expenses, especially in projects needing curved aesthetics or structural applications. Flat glass remains more affordable and widely available, making it a cost-effective choice for straightforward installations without intricate design demands.

Energy Efficiency and Insulation Properties

Bent glass offers superior energy efficiency compared to flat glass due to its ability to reduce solar heat gain and improve insulation in curved window designs. Its shape enhances thermal performance by minimizing air infiltration and allowing better distribution of insulating gases in double or triple-glazed units. Your choice of bent glass can significantly improve building insulation, lowering energy costs and enhancing indoor comfort.

Maintenance and Cleaning Requirements

Bent glass requires more careful maintenance due to its curved surfaces, which can accumulate dust and grime in crevices, making cleaning more challenging compared to flat glass. Specialized cleaning tools such as flexible squeegees and soft microfiber cloths are recommended to prevent scratches and maintain clarity on bent glass. Flat glass offers easier cleaning access with common glass cleaners and standard tools like squeegees and spray bottles, making routine maintenance quicker and less labor-intensive.

Choosing the Right Glass for Your Project

Bent glass offers enhanced structural strength and aesthetic appeal for curved architectural designs, making it ideal for projects requiring unique shapes and modern elegance. Flat glass is preferred for straightforward applications such as windows and doors due to its cost-effectiveness, ease of installation, and versatility in standard dimensions. Selecting between bent and flat glass depends on the project's design complexity, budget constraints, and functional requirements.

Bent glass vs flat glass Infographic

libmatt.com

libmatt.com