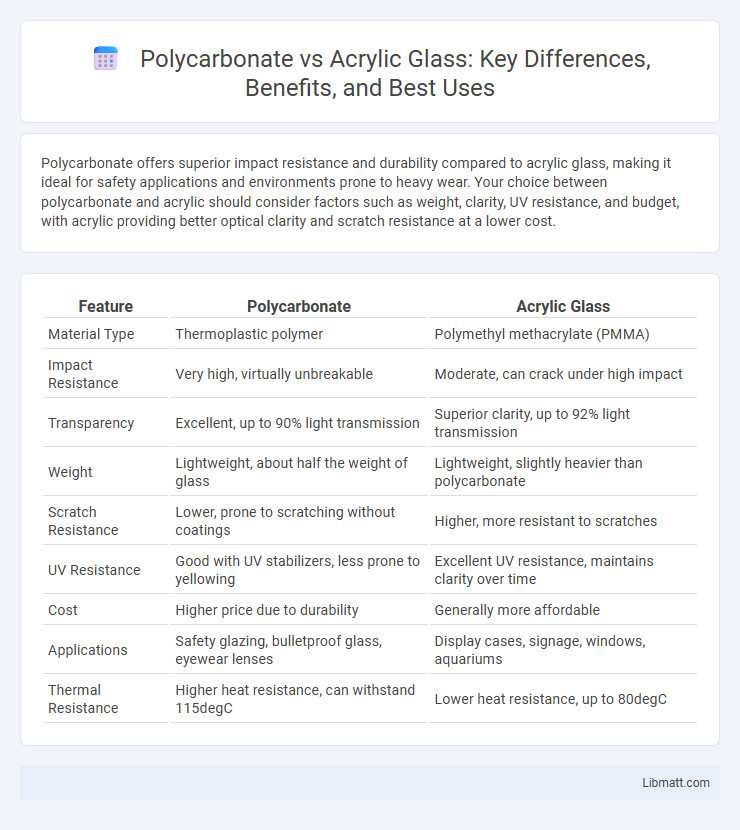

Polycarbonate offers superior impact resistance and durability compared to acrylic glass, making it ideal for safety applications and environments prone to heavy wear. Your choice between polycarbonate and acrylic should consider factors such as weight, clarity, UV resistance, and budget, with acrylic providing better optical clarity and scratch resistance at a lower cost.

Table of Comparison

| Feature | Polycarbonate | Acrylic Glass |

|---|---|---|

| Material Type | Thermoplastic polymer | Polymethyl methacrylate (PMMA) |

| Impact Resistance | Very high, virtually unbreakable | Moderate, can crack under high impact |

| Transparency | Excellent, up to 90% light transmission | Superior clarity, up to 92% light transmission |

| Weight | Lightweight, about half the weight of glass | Lightweight, slightly heavier than polycarbonate |

| Scratch Resistance | Lower, prone to scratching without coatings | Higher, more resistant to scratches |

| UV Resistance | Good with UV stabilizers, less prone to yellowing | Excellent UV resistance, maintains clarity over time |

| Cost | Higher price due to durability | Generally more affordable |

| Applications | Safety glazing, bulletproof glass, eyewear lenses | Display cases, signage, windows, aquariums |

| Thermal Resistance | Higher heat resistance, can withstand 115degC | Lower heat resistance, up to 80degC |

Introduction to Polycarbonate and Acrylic Glass

Polycarbonate and acrylic glass are popular transparent materials widely used in construction, automotive, and eyewear industries due to their excellent clarity and durability. Polycarbonate offers superior impact resistance and flexibility, making it ideal for protective gear and safety applications, while acrylic glass provides better scratch resistance and aesthetic appeal with a glass-like finish. Understanding the key differences between these materials will help you choose the best option based on your specific needs, balancing factors such as strength, weight, and cost.

Overview of Materials: Composition and Properties

Polycarbonate is a thermoplastic polymer known for its high impact resistance, optical clarity, and heat resistance, making it ideal for safety applications and durable glazing. Acrylic glass, or polymethyl methacrylate (PMMA), offers excellent transparency and weather resistance but is more brittle and less impact-resistant than polycarbonate. Understanding the different compositions and mechanical properties of these materials helps you select the right solution for applications requiring lightweight, clear, and strong alternatives to traditional glass.

Strength and Durability Comparison

Polycarbonate offers significantly higher impact resistance compared to acrylic glass, making it nearly unbreakable and ideal for applications requiring enhanced durability. Acrylic glass, while more prone to cracking under stress, provides superior scratch resistance and retains clarity better over time. Both materials are UV resistant, but polycarbonate's toughness makes it the preferred choice for safety glazing, protective barriers, and outdoor use where strength is critical.

Optical Clarity and Light Transmission

Polycarbonate offers excellent impact resistance but has slightly lower optical clarity compared to acrylic glass, which provides superior transparency and light transmission with up to 92% clarity. Acrylic glass exhibits minimal color distortion and higher light transmittance, making it ideal for applications requiring clear and bright visuals. Polycarbonate's light transmission typically ranges around 88-90%, making acrylic preferable when maximum optical performance is essential.

Weight Differences and Practical Implications

Polycarbonate weighs approximately half as much as acrylic glass, making it a more lightweight option for applications where reducing weight is crucial. This significant weight difference enhances portability and ease of installation, especially in large panels or protective barriers. Your choice impacts structural support requirements and overall handling efficiency in construction or design projects.

Impact Resistance: Polycarbonate vs. Acrylic

Polycarbonate offers significantly higher impact resistance than acrylic glass, with the ability to withstand impacts up to 250 times greater than standard glass, making it ideal for protective applications and safety glazing. Acrylic, while more impact-resistant than glass, is more prone to cracking and shattering under strong force, limiting its use in high-impact environments. Your choice between polycarbonate and acrylic should prioritize impact resistance needs, especially for security, industrial, or outdoor installations requiring durability and toughness.

Weather and UV Resistance Capabilities

Polycarbonate offers superior weather and UV resistance compared to acrylic glass, maintaining clarity and structural integrity under prolonged sun exposure and harsh conditions. While acrylic glass can resist UV radiation to a certain extent, it tends to yellow and become brittle faster than polycarbonate when exposed to outdoor environments. Choosing polycarbonate ensures better durability and longer-lasting protection for your outdoor applications.

Machinability and Fabrication Ease

Polycarbonate offers superior machinability compared to acrylic glass, allowing for easier cutting, drilling, and shaping without cracking or chipping. Its flexibility and impact resistance make polycarbonate ideal for fabrication processes that require bending or molding, whereas acrylic tends to be more brittle and prone to stress fractures. When planning your project, polycarbonate's ease of fabrication can save time and reduce material waste during machining.

Cost Analysis and Budget Considerations

Polycarbonate generally costs more than acrylic glass due to its superior impact resistance and durability, making it a better investment for high-stress applications. Acrylic glass offers a more budget-friendly option with good optical clarity and weather resistance, suitable for projects with moderate performance requirements. Evaluating the total cost of ownership, including maintenance and replacement frequency, is crucial when choosing between polycarbonate and acrylic glass.

Common Applications and Best Use Cases

Polycarbonate is commonly used in protective gear, safety windows, and eyewear lenses due to its high impact resistance and durability, making it ideal for environments requiring robust protection. Acrylic glass excels in applications like signage, display cases, and aquarium tanks where clarity and UV resistance are crucial for maintaining aesthetic appeal and transparency. Your choice between polycarbonate and acrylic glass should depend on the balance between impact strength and optical clarity required for your specific project.

polycarbonate vs acrylic glass Infographic

libmatt.com

libmatt.com