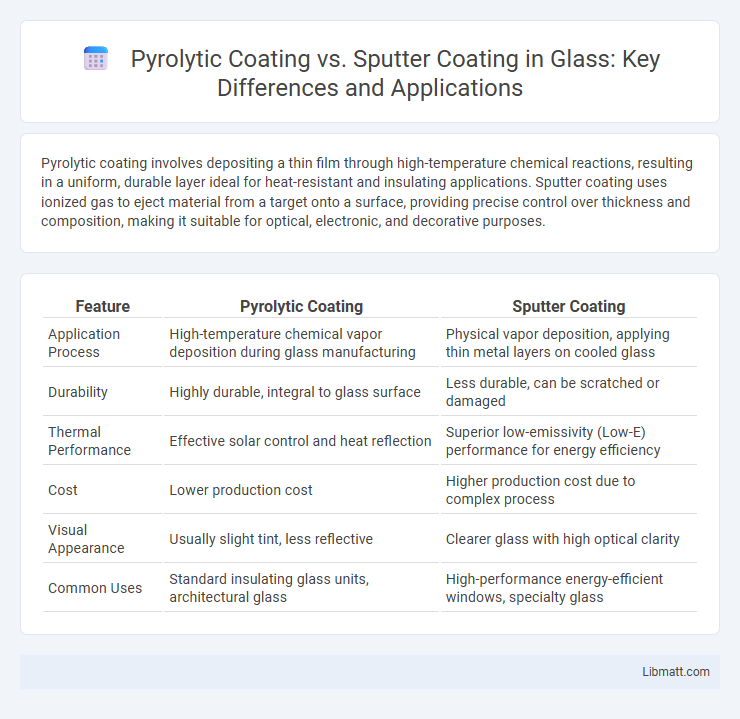

Pyrolytic coating involves depositing a thin film through high-temperature chemical reactions, resulting in a uniform, durable layer ideal for heat-resistant and insulating applications. Sputter coating uses ionized gas to eject material from a target onto a surface, providing precise control over thickness and composition, making it suitable for optical, electronic, and decorative purposes.

Table of Comparison

| Feature | Pyrolytic Coating | Sputter Coating |

|---|---|---|

| Application Process | High-temperature chemical vapor deposition during glass manufacturing | Physical vapor deposition, applying thin metal layers on cooled glass |

| Durability | Highly durable, integral to glass surface | Less durable, can be scratched or damaged |

| Thermal Performance | Effective solar control and heat reflection | Superior low-emissivity (Low-E) performance for energy efficiency |

| Cost | Lower production cost | Higher production cost due to complex process |

| Visual Appearance | Usually slight tint, less reflective | Clearer glass with high optical clarity |

| Common Uses | Standard insulating glass units, architectural glass | High-performance energy-efficient windows, specialty glass |

Introduction to Pyrolytic and Sputter Coating

Pyrolytic coating involves depositing a protective or functional layer on glass by high-temperature chemical vapor deposition, resulting in a durable, hard finish resistant to abrasion and corrosion. Sputter coating employs a vacuum-based physical vapor deposition method, where energetic ions eject material from a target to form a thin, uniform film with precise control over thickness and composition. Both techniques enhance glass properties but differ significantly in process temperature, film adhesion, and performance characteristics.

How Pyrolytic Coating Works

Pyrolytic coating works by applying a thin layer of metal oxide onto glass during the manufacturing process through high-temperature chemical vapor deposition, creating a durable, hard coating that improves thermal insulation and scratch resistance. This process bonds the coating directly to the glass surface, resulting in enhanced energy efficiency and long-lasting performance. Your windows benefit from the uniform, chemically fused layer that maintains clarity while optimizing solar control.

Sputter Coating: Process Overview

Sputter coating involves bombarding a target material with high-energy ions, causing atoms to eject and deposit onto a substrate as a thin film. This physical vapor deposition (PVD) process offers precise control over coating thickness and composition, making it ideal for semiconductor manufacturing and optical applications. Sputter coating produces dense, uniform layers with strong adhesion, superior to pyrolytic coatings in terms of film quality and versatility.

Key Material Differences

Pyrolytic coating involves the deposition of silicon dioxide or similar compounds at high temperatures, creating a durable, hard layer that enhances heat resistance and chemical stability on glass surfaces. Sputter coating uses a physical vapor deposition process to apply thin metallic or oxide films, offering precise control over thickness and composition, ideal for optical and electrical applications. Your choice depends on whether you prioritize high-temperature durability and chemical resistance (pyrolytic) or uniform, customizable thin films with specific optical or conductive properties (sputter).

Performance and Durability Comparison

Pyrolytic coating offers exceptional scratch resistance and thermal stability due to its chemically bonded layers, making it highly durable under harsh environmental conditions. Sputter coating provides superior optical clarity and precise thickness control but may exhibit lower abrasion resistance compared to pyrolytic options. Your choice should consider the specific application requirements, balancing the enhanced durability of pyrolytic coatings with the tailored performance characteristics of sputter coatings.

Applications of Pyrolytic Coating

Pyrolytic coating is widely used in architectural glass production for its durability, scratch resistance, and energy-efficient properties, making it ideal for insulating windows and solar control. This coating process enhances thermal insulation by creating a hard, transparent layer directly on the glass surface during manufacturing, which supports applications in building facades and automotive glass. Pyrolytic coatings also find use in cookware and electronic displays due to their resistance to heat and chemicals.

Applications of Sputter Coating

Sputter coating is widely used in semiconductor manufacturing for creating thin, uniform metal films essential for integrated circuits and microelectromechanical systems (MEMS). It is also crucial in producing optical coatings for lenses, mirrors, and display devices, enhancing durability and anti-reflective properties. Furthermore, sputter coating supports advanced research in material science by enabling surface analysis and the fabrication of nanoscale devices.

Environmental Impact and Sustainability

Pyrolytic coating typically involves higher energy consumption and emits volatile organic compounds, raising concerns about its environmental footprint. Sputter coating uses physical vapor deposition, which generally produces less hazardous waste and allows for precise material usage, enhancing sustainability. Selecting sputter coating can reduce ecological impact through lower emissions and improved resource efficiency in manufacturing processes.

Cost Considerations: Pyrolytic vs Sputter Coating

Pyrolytic coating generally incurs lower production costs due to its continuous roll-to-roll process and higher throughput, making it economical for large-scale applications. In contrast, sputter coating requires more expensive vacuum equipment and slower batch processing, increasing operational expenses. Cost efficiency in pyrolytic coating is favored for mass production, whereas sputter coating offers precision at a premium price point.

Choosing the Right Coating for Your Needs

Pyrolytic coating offers excellent durability and thermal insulation, making it ideal for energy-efficient windows, while sputter coating provides superior optical clarity and precise metallic layer control, suited for specialized optical applications. Your choice depends on whether you prioritize long-term heat resistance or exact optical performance in your project. Understanding the specific benefits of each coating ensures optimal functionality and cost-effectiveness tailored to your needs.

pyrolytic coating vs sputter coating Infographic

libmatt.com

libmatt.com