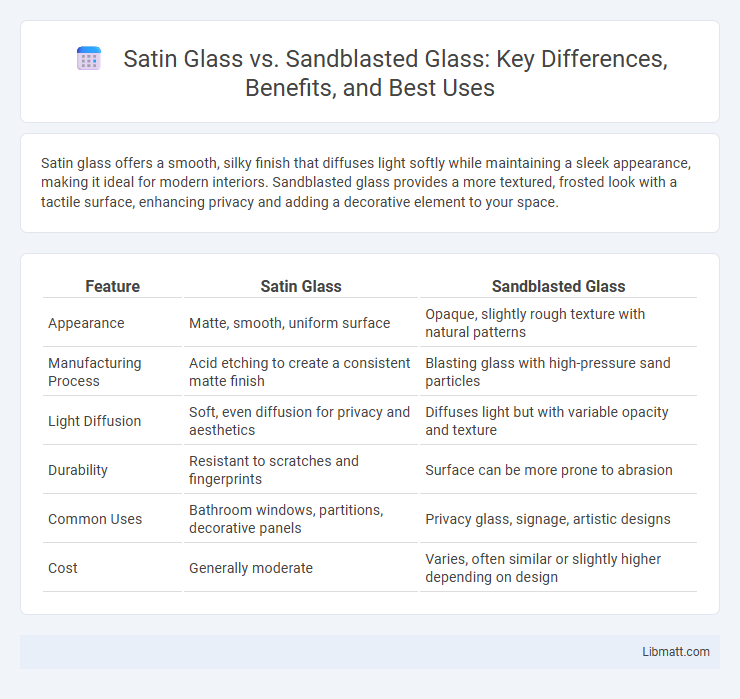

Satin glass offers a smooth, silky finish that diffuses light softly while maintaining a sleek appearance, making it ideal for modern interiors. Sandblasted glass provides a more textured, frosted look with a tactile surface, enhancing privacy and adding a decorative element to your space.

Table of Comparison

| Feature | Satin Glass | Sandblasted Glass |

|---|---|---|

| Appearance | Matte, smooth, uniform surface | Opaque, slightly rough texture with natural patterns |

| Manufacturing Process | Acid etching to create a consistent matte finish | Blasting glass with high-pressure sand particles |

| Light Diffusion | Soft, even diffusion for privacy and aesthetics | Diffuses light but with variable opacity and texture |

| Durability | Resistant to scratches and fingerprints | Surface can be more prone to abrasion |

| Common Uses | Bathroom windows, partitions, decorative panels | Privacy glass, signage, artistic designs |

| Cost | Generally moderate | Varies, often similar or slightly higher depending on design |

Introduction to Satin Glass and Sandblasted Glass

Satin glass features a smooth, matte finish achieved through acid etching or coating, providing a sleek, frosted appearance ideal for privacy while allowing diffused light transmission. Sandblasted glass undergoes abrasive blasting with high-pressure sand particles, creating a textured, opaque surface that enhances both aesthetics and durability. Your choice between satin and sandblasted glass depends on desired texture, light diffusion, and application needs in interior or exterior design.

Overview of Satin Glass: Definition and Manufacturing

Satin glass is a type of frosted glass characterized by its smooth, matte finish achieved through acid etching or coating processes, providing a soft, translucent appearance. Manufactured by exposing the glass surface to hydrofluoric acid or applying a satin spray, it diffuses light while maintaining partial visibility. This method creates a durable, elegant texture often used in architectural and interior design for privacy without compromising natural light.

Overview of Sandblasted Glass: Definition and Process

Sandblasted glass is created by propelling fine abrasive materials at high velocity onto the glass surface, producing a frosted, opaque appearance with a textured finish. This process enhances privacy while maintaining light diffusion, making it ideal for decorative and functional applications like partitions, doors, and windows. Unlike satin glass, which achieves a smooth matte look through chemical etching or coatings, sandblasting offers a more granular surface with increased tactile dimension.

Aesthetic Differences: Visual Comparison

Satin glass features a smooth, matte finish with a consistent, translucent appearance that softly diffuses light, creating a sleek and elegant look. Sandblasted glass exhibits a textured surface with a slightly rough, frosted effect that scatters light unevenly, adding depth and a handcrafted aesthetic to your space. Your choice between these finishes will influence the visual ambiance, with satin glass offering a more uniform glow and sandblasted glass providing a distinct tactile dimension.

Texture and Surface Finish

Satin glass features a smooth, matte surface created through acid etching, resulting in an even, soft texture that diffuses light while maintaining slight translucency. Sandblasted glass exhibits a rougher texture with a more granular, frosted appearance, achieved by propelling abrasive particles at high velocity onto the glass surface. The choice between satin and sandblasted finishes affects both tactile feel and light diffusion quality, with satin providing a gentler touch and uniform finish, while sandblasted offers a more textured and rustic aesthetic.

Light Diffusion and Privacy Levels

Satin glass offers a smooth, frosted finish that provides moderate light diffusion while maintaining a high level of privacy by obscuring visibility without completely blocking light. Sandblasted glass features a textured surface created by abrasive blasting, resulting in enhanced light diffusion that softens glare and increases privacy by making objects indistinct behind the glass. Both types are ideal for applications requiring privacy with natural light, but sandblasted glass typically delivers superior diffusion and obscurity compared to satin glass.

Durability and Maintenance Requirements

Satin glass features a smooth, matte finish created through acid etching or coating, offering moderate durability but requiring careful cleaning to avoid scratches and damage to the surface. Sandblasted glass undergoes abrasive blasting that produces a textured, frosted appearance, enhancing resistance to minor abrasions and making it easier to maintain with regular dusting and gentle washing. Both types demand non-abrasive cleaners to preserve their finishes, but sandblasted glass generally withstands wear better in high-traffic areas.

Common Applications and Best Uses

Satin glass is commonly used in interiors for privacy windows, shower enclosures, and cabinet doors due to its smooth, translucent surface that diffuses light while obscuring visibility. Sandblasted glass is ideal for decorative panels, signage, and architectural features where intricate patterns or textures are required, offering a frosted finish created by abrasive blasting. Both types enhance aesthetic appeal and privacy but satin glass suits softer, uniform light diffusion, whereas sandblasted glass excels in detailed design applications.

Cost Comparison: Satin Glass vs Sandblasted Glass

Satin glass typically costs less than sandblasted glass due to its simpler manufacturing process involving acid etching, while sandblasted glass requires specialized equipment to blast abrasive material onto the surface, increasing production expenses. Your choice may impact budget considerations as sandblasted glass often demands higher labor and material costs, making it a premium option for decorative or privacy applications. Comparing prices, satin glass offers an affordable alternative with a smooth, frosted appearance, whereas sandblasted glass provides more detailed and textured designs at a higher price point.

Choosing the Right Glass for Your Project

Choosing between satin glass and sandblasted glass depends on the desired texture and light diffusion for your project. Satin glass offers a smooth, uniform finish with subtle translucency, ideal for privacy while maintaining brightness. Sandblasted glass provides a more textured, frosted appearance with enhanced mattification, perfect for decorative panels and areas where a higher degree of opacity is required.

satin glass vs sandblasted glass Infographic

libmatt.com

libmatt.com