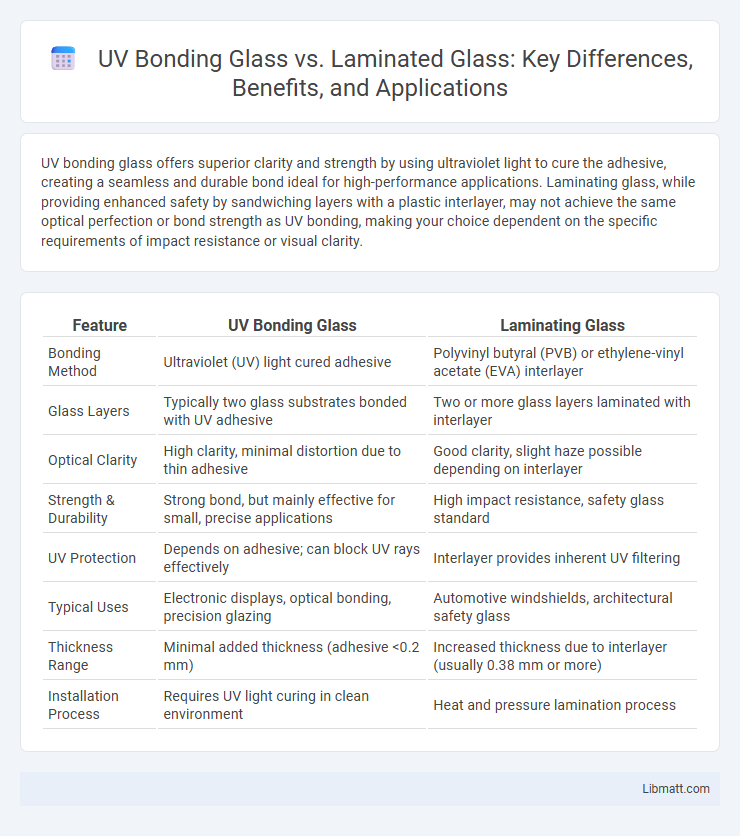

UV bonding glass offers superior clarity and strength by using ultraviolet light to cure the adhesive, creating a seamless and durable bond ideal for high-performance applications. Laminating glass, while providing enhanced safety by sandwiching layers with a plastic interlayer, may not achieve the same optical perfection or bond strength as UV bonding, making your choice dependent on the specific requirements of impact resistance or visual clarity.

Table of Comparison

| Feature | UV Bonding Glass | Laminating Glass |

|---|---|---|

| Bonding Method | Ultraviolet (UV) light cured adhesive | Polyvinyl butyral (PVB) or ethylene-vinyl acetate (EVA) interlayer |

| Glass Layers | Typically two glass substrates bonded with UV adhesive | Two or more glass layers laminated with interlayer |

| Optical Clarity | High clarity, minimal distortion due to thin adhesive | Good clarity, slight haze possible depending on interlayer |

| Strength & Durability | Strong bond, but mainly effective for small, precise applications | High impact resistance, safety glass standard |

| UV Protection | Depends on adhesive; can block UV rays effectively | Interlayer provides inherent UV filtering |

| Typical Uses | Electronic displays, optical bonding, precision glazing | Automotive windshields, architectural safety glass |

| Thickness Range | Minimal added thickness (adhesive <0.2 mm) | Increased thickness due to interlayer (usually 0.38 mm or more) |

| Installation Process | Requires UV light curing in clean environment | Heat and pressure lamination process |

Introduction to UV Bonding Glass and Laminating Glass

UV bonding glass utilizes ultraviolet light to cure specialized adhesives, creating a strong, gap-free bond that enhances optical clarity and structural integrity. Laminating glass consists of multiple glass layers bonded together with an interlayer, typically polyvinyl butyral (PVB), providing safety features by holding fragments in place upon impact. These technologies serve distinct purposes: UV bonding excels in seamless assembly and display applications, while laminating glass is integral to automotive, architectural, and safety glazing for impact resistance.

Understanding UV Bonding Glass: Process and Applications

UV bonding glass utilizes ultraviolet light to cure a transparent adhesive that creates a strong optical bond between glass layers, enhancing clarity and structural integrity without bubbles or haze. This process is widely applied in touchscreen displays, automotive glass, and architectural glazing where precision and durability are critical. Your choice of UV bonding glass can improve impact resistance and reduce reflections, making it ideal for high-performance visual and structural applications.

Overview of Laminating Glass: Techniques and Uses

Laminating glass involves bonding two or more glass layers with an interlayer, commonly polyvinyl butyral (PVB) or ethylene-vinyl acetate (EVA), providing enhanced safety, sound insulation, and UV protection. Techniques include heat and pressure application to fuse glass and interlayers, resulting in impact-resistant and shatterproof panels widely used in automotive windshields, architectural glazing, and solar panels. This method improves durability, reduces injury risk from broken glass, and enhances optical clarity, distinguishing it from UV bonding glass which relies on ultraviolet-curable adhesives for precise assembly in electronics or specialty glass products.

Key Differences Between UV Bonding and Laminating Glass

UV bonding glass uses ultraviolet light to cure adhesive layers that permanently fuse glass components, providing superior clarity and strength ideal for touchscreens and optical devices. Laminating glass involves sandwiching a plastic interlayer between two glass sheets, enhancing safety by holding shards together upon breakage and improving impact resistance in automotive and architectural applications. The key difference lies in UV bonding's focus on optical performance and durability without interlayers, whereas laminating prioritizes safety and structural integrity through sandwich construction.

Strength and Durability Comparison

UV bonding glass offers superior strength and durability due to the polymer adhesive's strong molecular bonding, creating a uniform and rigid structure that resists delamination under stress. Laminating glass consists of layers of glass bonded with an interlayer, typically PVB or EVA, which provides impact resistance and prevents shattering but may be less rigid under prolonged mechanical load compared to UV bonding. The enhanced durability of UV bonding makes it ideal for applications requiring high structural integrity and resistance to environmental factors such as moisture and UV radiation.

Optical Clarity and Aesthetic Results

UV bonding glass provides superior optical clarity by eliminating visible gaps and minimizing light refraction, resulting in a seamless and crystal-clear appearance. Laminating glass often contains interlayers that can slightly reduce transparency and introduce minor haze, affecting the overall visual quality. The UV bonding method enhances aesthetic results by maintaining the glass's natural brilliance and sharpness, ideal for applications requiring pristine, high-clarity finishes.

Safety and Security Considerations

UV bonding glass offers enhanced safety by creating a strong, seamless bond between glass layers that resists impact and reduces the risk of shattering into sharp fragments. Laminating glass incorporates a polyvinyl butyral (PVB) interlayer that holds shattered glass pieces together, providing superior security against forced entry and improving resistance to penetration. Both technologies improve occupant protection, but laminated glass is often preferred for high-security applications due to its ability to maintain structural integrity upon impact.

Cost Analysis: UV Bonding vs Laminating Glass

UV bonding glass typically incurs higher initial costs due to specialized adhesives and curing equipment, whereas laminating glass offers a more cost-effective solution with standard interlayer materials and simpler processing. Maintenance and durability expenses are lower for UV bonded glass, as the strong chemical bond enhances longevity and reduces delamination risks compared to laminated glass. Total cost analysis reveals that UV bonding glass delivers superior value for high-performance applications despite its upfront investment, while laminated glass remains a budget-friendly choice for general safety glazing.

Suitable Applications for Each Method

UV bonding glass is ideal for applications requiring high optical clarity and strong adhesion without added layers, commonly used in touchscreen displays, optical lenses, and medical devices. Laminating glass suits safety and structural purposes, such as automotive windshields, architectural glazing, and protective barriers, by integrating a polymer interlayer that enhances impact resistance. Each method optimizes performance based on the intended use, balancing transparency, durability, and safety requirements.

Choosing the Right Technique: Factors to Consider

UV bonding glass offers superior optical clarity and strong adhesion ideal for high-precision applications, while laminating glass provides enhanced safety through interlayers that hold shards together upon impact. Consider your project's durability requirements, exposure to environmental elements, and desired aesthetic finish when selecting between these techniques. Understanding these factors ensures your glass assembly meets performance standards and longevity expectations.

UV bonding glass vs laminating glass Infographic

libmatt.com

libmatt.com