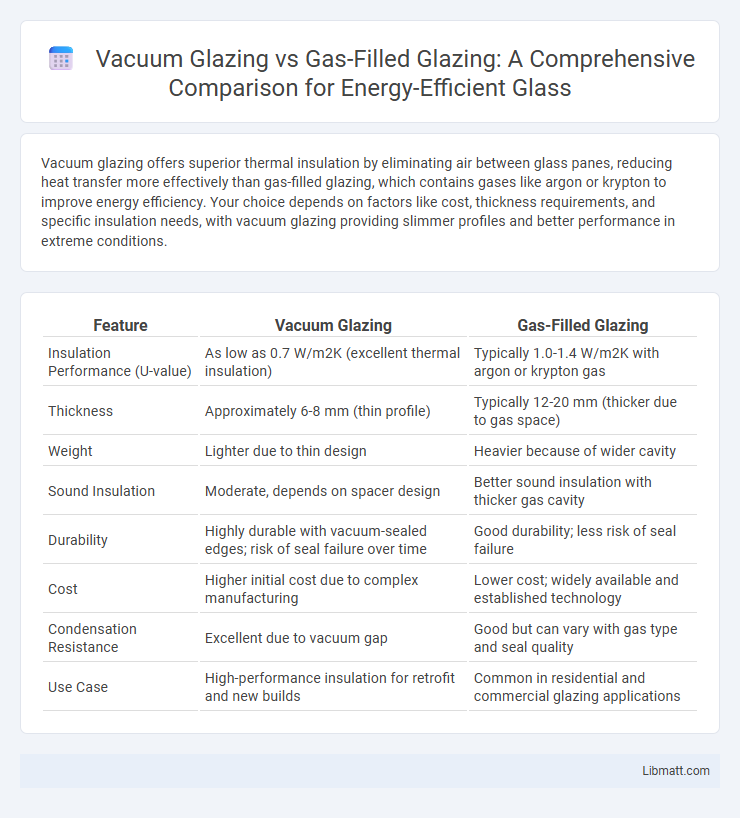

Vacuum glazing offers superior thermal insulation by eliminating air between glass panes, reducing heat transfer more effectively than gas-filled glazing, which contains gases like argon or krypton to improve energy efficiency. Your choice depends on factors like cost, thickness requirements, and specific insulation needs, with vacuum glazing providing slimmer profiles and better performance in extreme conditions.

Table of Comparison

| Feature | Vacuum Glazing | Gas-Filled Glazing |

|---|---|---|

| Insulation Performance (U-value) | As low as 0.7 W/m2K (excellent thermal insulation) | Typically 1.0-1.4 W/m2K with argon or krypton gas |

| Thickness | Approximately 6-8 mm (thin profile) | Typically 12-20 mm (thicker due to gas space) |

| Weight | Lighter due to thin design | Heavier because of wider cavity |

| Sound Insulation | Moderate, depends on spacer design | Better sound insulation with thicker gas cavity |

| Durability | Highly durable with vacuum-sealed edges; risk of seal failure over time | Good durability; less risk of seal failure |

| Cost | Higher initial cost due to complex manufacturing | Lower cost; widely available and established technology |

| Condensation Resistance | Excellent due to vacuum gap | Good but can vary with gas type and seal quality |

| Use Case | High-performance insulation for retrofit and new builds | Common in residential and commercial glazing applications |

Introduction to Vacuum and Gas-Filled Glazing

Vacuum glazing uses a near-vacuum space between two glass panes to reduce heat transfer by minimizing conduction and convection, achieving superior insulation performance compared to traditional gas-filled glazing, which relies on inert gases like argon or krypton to slow heat flow. Vacuum glazing offers thinner units with higher thermal efficiency, making it ideal for space-constrained applications where maximizing insulation and minimizing weight are crucial. Your choice between these technologies depends on factors such as cost, thermal performance requirements, and the specific environmental conditions of your building project.

How Vacuum Glazing Works

Vacuum glazing consists of two glass panes separated by a narrow vacuum gap that eliminates heat transfer through conduction and convection. Tiny support pillars maintain the gap, preventing the panes from collapsing while enabling excellent thermal insulation. This technology significantly reduces energy loss compared to gas-filled glazing, where inert gases like argon or krypton fill the space to slow heat transfer but cannot eliminate it completely.

Principles of Gas-Filled Glazing

Gas-filled glazing utilizes inert gases such as argon or krypton trapped between two glass panes to reduce thermal conductivity and enhance insulation performance. The gas layer minimizes heat transfer by convection and conduction, improving energy efficiency in windows. This method contrasts vacuum glazing, which eliminates gas entirely to create a near-vacuum space for superior thermal resistance.

Energy Efficiency Comparison

Vacuum glazing significantly reduces heat transfer by creating a near-perfect vacuum between glass panes, minimizing conduction and convection, which leads to superior energy efficiency compared to gas-filled glazing that relies on inert gases like argon or krypton to improve insulation. The thermal conductivity of vacuum glazing is typically around 0.1 W/m2K, whereas gas-filled glazing usually ranges from 1.0 to 2.0 W/m2K, demonstrating a notable advantage in reducing heat loss. This enhanced insulation capability of vacuum glazing results in lower heating and cooling energy costs and improved overall building energy performance.

Thermal Insulation Performance

Vacuum glazing offers superior thermal insulation performance by eliminating gas convection and reducing conductive heat transfer through its vacuum space, achieving U-values as low as 0.5 W/m2K. Gas-filled glazing, typically filled with argon or krypton, improves insulation by slowing heat transfer but generally attains higher U-values around 1.0 to 1.2 W/m2K. For your highest energy efficiency needs, vacuum glazing provides enhanced insulation in thinner profiles compared to gas-filled options.

Noise Reduction Capabilities

Vacuum glazing offers superior noise reduction capabilities by creating a near-vacuum space that eliminates air molecules responsible for sound transmission, effectively reducing external noise levels up to 30 decibels. Gas-filled glazing, typically filled with argon or krypton gas, provides moderate noise insulation by increasing the density between panes, diminishing sound penetration by approximately 20 decibels. The thermally broken vacuum cavity in vacuum glazing also minimizes sound vibrations better than the denser gas-filled gaps, making it preferable for high-performance acoustic insulation.

Durability and Longevity

Vacuum glazing offers superior durability due to its robust, hermetically sealed design that prevents gas leakage and maintains thermal performance over decades. Gas-filled glazing, typically using argon or krypton gas, can experience gas diffusion over time, reducing insulation effectiveness and compromising longevity. The vacuum gap in vacuum glazing eliminates the risk of gas displacement, ensuring consistent thermal insulation and structural integrity for 30 to 50 years or more.

Installation and Maintenance Considerations

Vacuum glazing requires precise installation to maintain the vacuum seal and prevent air ingress, making professional handling essential, while gas-filled glazing is more forgiving with installation and can be fitted using standard double-glazing techniques. Maintenance for vacuum glazing is minimal due to its robust seal, but any breach typically necessitates complete unit replacement, whereas gas-filled glazing may experience gas leakage over time, reducing insulation performance and requiring periodic checks. Your choice should factor in installation complexity and long-term maintenance demands to ensure optimal energy efficiency and durability.

Cost and Return on Investment

Vacuum glazing typically incurs higher initial costs due to advanced manufacturing processes and specialized sealing techniques compared to gas-filled glazing, which uses more established production methods. Despite the higher upfront investment, vacuum glazing offers superior thermal insulation and long-term energy savings, leading to a faster return on investment in climates with extreme temperature variations. Gas-filled glazing often provides a more cost-effective solution upfront but may result in longer payback periods due to lower insulation performance.

Choosing the Right Glazing Solution

Vacuum glazing offers superior thermal insulation with a thinner profile by eliminating gas layers, making it ideal for space-constrained applications requiring high energy efficiency. Gas-filled glazing, typically filled with argon or krypton, provides effective insulation with enhanced soundproofing at a lower cost, suitable for conventional window replacements. Selecting the right glazing solution depends on factors such as thermal performance requirements, space limitations, budget constraints, and specific application needs.

vacuum glazing vs gas-filled glazing Infographic

libmatt.com

libmatt.com