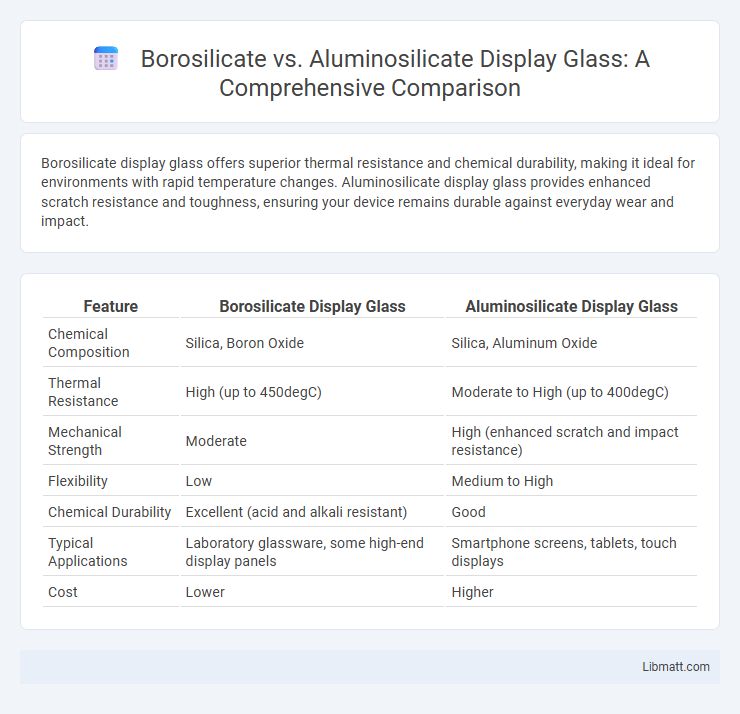

Borosilicate display glass offers superior thermal resistance and chemical durability, making it ideal for environments with rapid temperature changes. Aluminosilicate display glass provides enhanced scratch resistance and toughness, ensuring your device remains durable against everyday wear and impact.

Table of Comparison

| Feature | Borosilicate Display Glass | Aluminosilicate Display Glass |

|---|---|---|

| Chemical Composition | Silica, Boron Oxide | Silica, Aluminum Oxide |

| Thermal Resistance | High (up to 450degC) | Moderate to High (up to 400degC) |

| Mechanical Strength | Moderate | High (enhanced scratch and impact resistance) |

| Flexibility | Low | Medium to High |

| Chemical Durability | Excellent (acid and alkali resistant) | Good |

| Typical Applications | Laboratory glassware, some high-end display panels | Smartphone screens, tablets, touch displays |

| Cost | Lower | Higher |

Introduction to Display Glass Types

Borosilicate display glass offers superior thermal resistance and chemical durability, making it ideal for high-temperature manufacturing processes and harsh environments. Aluminosilicate display glass provides enhanced impact resistance and scratch protection, commonly used in smartphones and tablets for improved device durability. Both glass types are engineered to optimize optical clarity and mechanical strength, catering to the specific performance requirements of modern electronic displays.

What is Borosilicate Display Glass?

Borosilicate display glass is a type of glass known for its exceptional thermal and chemical resistance, commonly used in high-performance electronic displays. It features a low coefficient of thermal expansion, which minimizes the risk of cracking under temperature fluctuations, making it ideal for devices exposed to rapid heating and cooling. Your choice of borosilicate glass ensures durability and clarity, especially where resistance to thermal shock is a priority compared to aluminosilicate glass.

What is Aluminosilicate Display Glass?

Aluminosilicate display glass is a high-strength, chemically durable material primarily used in smartphone and tablet screens for enhanced scratch and impact resistance. It features a unique composition that includes aluminum oxide, boosting its mechanical toughness compared to traditional soda-lime and borosilicate glasses. You benefit from superior durability and better protection against daily wear and drops, making aluminosilicate glass a preferred choice for modern electronic devices.

Chemical Composition Comparison

Borosilicate display glass primarily consists of silica (SiO2) and boron trioxide (B2O3), which provides excellent thermal and chemical resistance, making it ideal for high-temperature applications. Aluminosilicate display glass contains silica (SiO2) and alumina (Al2O3), offering superior mechanical strength and scratch resistance due to the increased aluminum content. The key chemical difference lies in the boron oxide concentration in borosilicate glass versus the aluminum oxide concentration in aluminosilicate glass, influencing their thermal stability and durability properties.

Strength and Durability Differences

Borosilicate display glass offers excellent thermal resistance and moderate strength, making it highly durable against heat-induced stress but slightly less impact-resistant compared to aluminosilicate glass. Aluminosilicate display glass delivers superior surface strength and enhanced resistance to scratches and drops, making it the preferred choice for smartphone and tablet screens. Understanding these strength and durability differences helps you choose the glass type best suited for your device's specific performance and longevity needs.

Scratch and Impact Resistance

Borosilicate display glass offers excellent thermal stability but generally provides lower scratch resistance compared to aluminosilicate display glass, which is engineered to withstand daily wear and tear more effectively. Aluminosilicate glass, often chemically strengthened through ion exchange, delivers superior impact resistance, making it the preferred choice for smartphones and rugged devices. You benefit from aluminosilicate glass's enhanced durability in both scratch and impact resistance, ensuring longer-lasting screen protection.

Thermal Stability and Heat Resistance

Borosilicate display glass offers superior thermal stability and heat resistance due to its low thermal expansion coefficient, making it highly resistant to cracking under rapid temperature changes. Aluminosilicate display glass provides enhanced durability and scratch resistance but has a slightly higher thermal expansion, which may affect performance under extreme thermal stress. For applications requiring exceptional heat resistance and dimensional stability, borosilicate glass is often preferred to ensure your display maintains clarity and integrity in high-temperature environments.

Optical Clarity and Display Performance

Borosilicate display glass offers excellent optical clarity with high light transmittance and minimal distortion, ensuring sharp and vivid visuals for your device. Aluminosilicate display glass provides superior strength and scratch resistance while maintaining comparable clarity, supporting vibrant display performance even under rough conditions. Your choice depends on prioritizing either enhanced durability with aluminosilicate or the exceptional transparency and stability of borosilicate.

Cost and Manufacturing Considerations

Borosilicate display glass offers lower manufacturing costs due to its simpler production process and widespread availability of raw materials, making it a cost-effective option for various electronic devices. Aluminosilicate display glass, while more expensive, provides superior strength and scratch resistance, justifying higher costs in premium smartphones and tablets with demanding durability requirements. Manufacturers often balance cost and performance by selecting borosilicate for budget-conscious models and aluminosilicate for high-end displays needing enhanced structural integrity.

Best Applications for Each Glass Type

Borosilicate display glass excels in applications requiring high thermal resistance and chemical durability, making it ideal for laboratory instruments, specialty lighting, and certain electronic displays exposed to harsh environments. Aluminosilicate display glass offers superior scratch resistance and mechanical strength, which suits smartphones, tablets, and wearable devices that demand daily impact and abrasion protection. Choosing the right glass for your display hinges on balancing thermal performance needs with durability and scratch resistance requirements.

borosilicate display glass vs aluminosilicate display glass Infographic

libmatt.com

libmatt.com