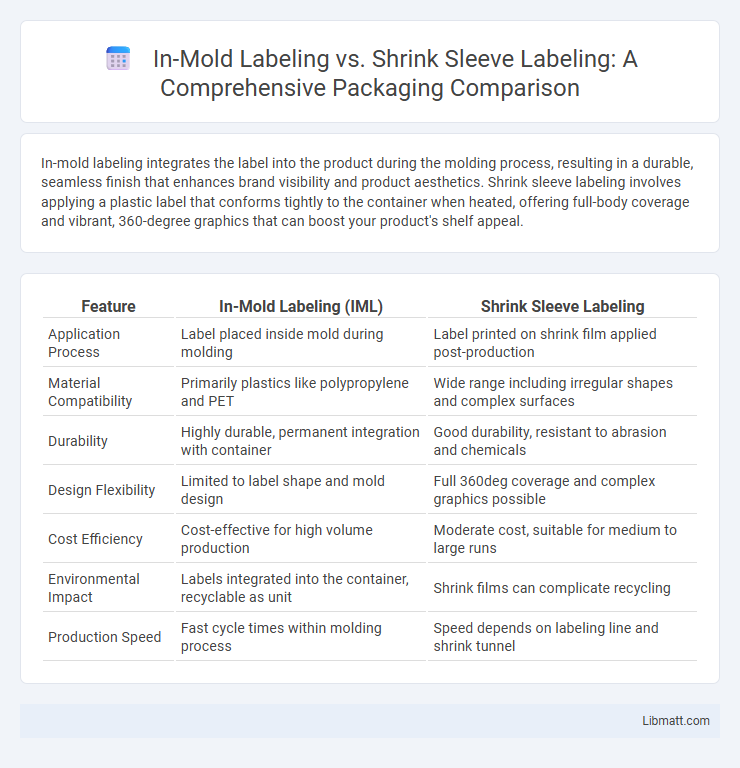

In-mold labeling integrates the label into the product during the molding process, resulting in a durable, seamless finish that enhances brand visibility and product aesthetics. Shrink sleeve labeling involves applying a plastic label that conforms tightly to the container when heated, offering full-body coverage and vibrant, 360-degree graphics that can boost your product's shelf appeal.

Table of Comparison

| Feature | In-Mold Labeling (IML) | Shrink Sleeve Labeling |

|---|---|---|

| Application Process | Label placed inside mold during molding | Label printed on shrink film applied post-production |

| Material Compatibility | Primarily plastics like polypropylene and PET | Wide range including irregular shapes and complex surfaces |

| Durability | Highly durable, permanent integration with container | Good durability, resistant to abrasion and chemicals |

| Design Flexibility | Limited to label shape and mold design | Full 360deg coverage and complex graphics possible |

| Cost Efficiency | Cost-effective for high volume production | Moderate cost, suitable for medium to large runs |

| Environmental Impact | Labels integrated into the container, recyclable as unit | Shrink films can complicate recycling |

| Production Speed | Fast cycle times within molding process | Speed depends on labeling line and shrink tunnel |

Introduction to Labeling Technologies

In-mold labeling (IML) integrates the label directly into the container during the molding process, resulting in a durable, high-quality finish with excellent resistance to wear and chemicals. Shrink sleeve labeling uses heat to conform a printed polypropylene or PET film tightly around the container, offering 360-degree design coverage and versatile shape adaptation. Your choice between these advanced labeling technologies depends on factors like production speed, label durability, and marketing impact.

What is In-Mold Labeling (IML)?

In-Mold Labeling (IML) is a process where pre-printed labels are placed inside a mold before the plastic injection process, allowing the label to become an integral part of the product's surface during molding. This technique ensures superior durability, resistance to wear and tear, and high-quality graphics that won't peel or fade over time. If you're aiming for a seamless, long-lasting label that enhances product appearance and withstands harsh conditions, IML offers distinct advantages over traditional shrink sleeve labeling.

What is Shrink Sleeve Labeling?

Shrink sleeve labeling is a packaging technique where a polyester or polyvinyl chloride film is printed, cut, and then formed around a product container before heat is applied to shrink the sleeve tightly onto the surface. This method provides 360-degree coverage and allows for intricate, full-color graphics that conform to complex container shapes. It is widely used in industries like food and beverage, cosmetics, and household products due to its durability and visually appealing finish.

Material and Printing Differences

In-mold labeling (IML) utilizes polypropylene or polyethylene films that are integrated into the container during the molding process, ensuring durability and a seamless finish, while shrink sleeve labeling employs polyvinyl chloride (PVC), polyethylene terephthalate glycol (PETG), or polypropylene shrink films that conform tightly around packaging after application. Printing for IML typically involves high-resolution rotogravure or flexographic techniques with heat-resistant inks designed to withstand molding temperatures, whereas shrink sleeve labeling uses water-based or solvent-based flexographic and UV printing methods optimized for film flexibility and shrink performance. These material and printing distinctions impact label durability, visual quality, and production efficiencies, making IML ideal for rigid containers and shrink sleeves better suited for complex shapes and full 360-degree graphics.

Application Processes Compared

In-mold labeling integrates the label directly into the container during the molding process, offering a seamless, durable decoration that resists wear and tear. Shrink sleeve labeling involves applying a printed plastic film around a container, which is then heat-shrunk to conform tightly, allowing 360-degree coverage with vibrant graphics. Understanding these distinct application processes helps you select the ideal labeling method for your product's design complexity and durability requirements.

Design Flexibility and Visual Impact

In-mold labeling (IML) offers superior design flexibility by integrating the label directly into the container during the molding process, allowing for vibrant, high-resolution graphics that are durable and resistant to wear. Shrink sleeve labeling, however, provides a 360-degree wrap that enables complex designs and full-body coverage, enhancing visual impact with seamless, eye-catching effects. You can choose IML for sleek, embedded designs or shrink sleeves for bold, all-around packaging aesthetics that stand out on shelves.

Durability and Resistance

In-mold labeling provides superior durability and resistance by fusing the label directly into the container during the molding process, resulting in enhanced abrasion, chemical, and moisture resistance. Shrink sleeve labeling offers excellent resistance to moisture and chemicals but is more prone to wear and peeling over time, especially under harsh environmental conditions. Your choice should consider the product's exposure to physical and chemical stress to ensure optimal label longevity.

Sustainability and Environmental Considerations

In-mold labeling (IML) offers superior sustainability by integrating the label into the container during molding, eliminating separate label waste and enhancing recyclability of the entire package. Shrink sleeve labeling, while providing 360-degree coverage, often uses multi-material films that complicate recycling processes and increase environmental impact. Choosing IML supports circular economy goals by reducing plastic use and facilitating streamlined recycling systems.

Cost Analysis and Production Efficiency

In-mold labeling (IML) offers cost advantages through reduced labor and material waste by integrating labels during the molding process, enhancing production efficiency with faster cycle times and less post-production handling. Shrink sleeve labeling incurs higher material costs and additional steps for applying and heat shrinking, which can slow down throughput and increase labor expenses. Your choice depends on volume and budget constraints, with IML favoring high-volume runs due to lower per-unit costs and superior automation compatibility.

Choosing the Right Labeling Method

Choosing the right labeling method depends on factors such as product shape, durability requirements, and production volume. In-mold labeling integrates the label directly into the container during the molding process, offering excellent durability and a seamless appearance ideal for high-volume runs. Shrink sleeve labeling provides full-body coverage with vibrant graphics and flexibility for complex shapes but may involve additional processing steps and costs.

In-mold labeling vs shrink sleeve labeling Infographic

libmatt.com

libmatt.com