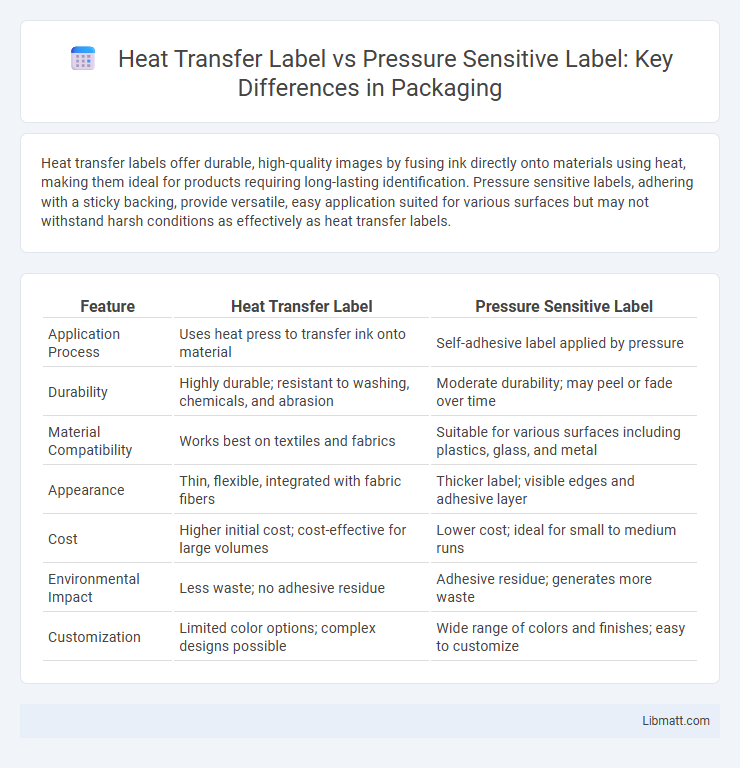

Heat transfer labels offer durable, high-quality images by fusing ink directly onto materials using heat, making them ideal for products requiring long-lasting identification. Pressure sensitive labels, adhering with a sticky backing, provide versatile, easy application suited for various surfaces but may not withstand harsh conditions as effectively as heat transfer labels.

Table of Comparison

| Feature | Heat Transfer Label | Pressure Sensitive Label |

|---|---|---|

| Application Process | Uses heat press to transfer ink onto material | Self-adhesive label applied by pressure |

| Durability | Highly durable; resistant to washing, chemicals, and abrasion | Moderate durability; may peel or fade over time |

| Material Compatibility | Works best on textiles and fabrics | Suitable for various surfaces including plastics, glass, and metal |

| Appearance | Thin, flexible, integrated with fabric fibers | Thicker label; visible edges and adhesive layer |

| Cost | Higher initial cost; cost-effective for large volumes | Lower cost; ideal for small to medium runs |

| Environmental Impact | Less waste; no adhesive residue | Adhesive residue; generates more waste |

| Customization | Limited color options; complex designs possible | Wide range of colors and finishes; easy to customize |

Introduction to Heat Transfer Labels and Pressure Sensitive Labels

Heat transfer labels use a heat-activated process to embed designs onto fabrics, providing durable and vibrant graphics without adding extra layers. Pressure sensitive labels rely on an adhesive backing that bonds instantly to surfaces with light pressure, offering quick application and versatility for various materials. Understanding these labeling methods helps you choose the best solution based on durability, fabric compatibility, and application ease.

Key Differences Between Heat Transfer and Pressure Sensitive Labels

Heat transfer labels use a thermal print process to transfer ink from a ribbon to the substrate, offering durability and resistance to abrasion, chemicals, and heat, ideal for applications requiring long-lasting identification. Pressure sensitive labels rely on an adhesive backing that sticks directly to surfaces without heat, providing quick application and versatility across various materials but may have lower durability in harsh environments. Your choice depends on the required label longevity, environmental exposure, and substrate compatibility for optimal performance.

Material Composition and Construction

Heat transfer labels consist of a carrier film coated with a heat-sensitive resin that adheres to fabric when exposed to heat and pressure, ensuring durability on textiles. Pressure sensitive labels feature a backing material, adhesive layer, and a protective liner, allowing them to stick instantly to various surfaces without heat application. Your choice between these labels depends on the substrate compatibility and environmental durability required for the application.

Application Processes Compared

Heat transfer labels are applied using a heat press that transfers dye-based inks onto fabrics, providing durable, vibrant designs ideal for sportswear and uniforms. Pressure sensitive labels utilize adhesive backing that bonds instantly to surfaces through pressure, making them suitable for quick, versatile application on products like packaging and containers. Your choice depends on whether you need high durability and color vibrancy or fast, easy adhesion for diverse substrates.

Durability and Longevity of Each Label Type

Heat transfer labels offer superior durability and longevity due to their ability to bond directly with fabric fibers, making them resistant to washing, abrasion, and fading over time. Pressure sensitive labels, while easy to apply, tend to have a shorter lifespan as their adhesive can weaken with exposure to moisture, heat, and friction. For applications requiring long-lasting identification, your choice of heat transfer labels ensures a more reliable and enduring solution compared to pressure sensitive labels.

Visual Appeal and Design Capabilities

Heat transfer labels offer exceptional visual appeal with vibrant colors and intricate designs due to their high-resolution printing technology, making them ideal for detailed logos and complex graphics. Pressure sensitive labels provide versatile design options with a wide range of finishes, including matte, glossy, and textured surfaces, enhancing tactile and visual customization. Both label types support durability, but heat transfer labels excel in seamless application on curved and textured surfaces without edges or peeling.

Cost Analysis: Heat Transfer vs Pressure Sensitive Labels

Heat transfer labels generally incur higher initial setup costs due to the need for specialized equipment and engraving plates, but they offer cost efficiency in large production runs because of their durability and reduced waste. Pressure sensitive labels involve lower upfront expenses and are versatile for small batches or varied designs, though higher material costs and potential label waste can increase overall expenditure in mass production. Your choice depends on production volume, with heat transfer labels favored for long-term cost savings and pressure sensitive labels preferred for flexibility and short-term projects.

Best Use Cases for Heat Transfer Labels

Heat transfer labels excel in applications requiring durable, high-resolution graphics on garments, especially for sportswear, promotional apparel, and corporate uniforms. Their resistance to repeated washing, stretching, and abrasion makes them ideal for activewear and workwear that undergo frequent laundering. These labels provide a smooth, flexible finish that adheres directly to fabric fibers without adding bulk, ensuring comfort and longevity in demanding environments.

Ideal Applications for Pressure Sensitive Labels

Pressure sensitive labels are ideal for applications requiring quick and easy labeling on various surfaces, including plastics, glass, metals, and paper, in industries like food and beverage, pharmaceuticals, and cosmetics. Their adhesive properties allow for strong, durable bonds even on irregular or curved surfaces, making them suitable for high-speed production lines and retail packaging. Your choice of pressure sensitive labels ensures efficient application and excellent durability in environments exposed to moisture, temperature changes, and handling.

Environmental Impact and Sustainability Considerations

Heat transfer labels typically use polyester films and involve a high-energy printing process, which can result in increased carbon emissions and challenges in recycling due to the film's composite nature. Pressure sensitive labels often use paper or PVC materials with adhesives that may hinder recyclability but increasingly incorporate biodegradable or removable adhesives to enhance sustainability. Choosing pressure sensitive labels with eco-friendly adhesives and recyclable substrates minimizes environmental impact compared to the energy-intensive production and disposal concerns associated with heat transfer labels.

Heat transfer label vs pressure sensitive label Infographic

libmatt.com

libmatt.com