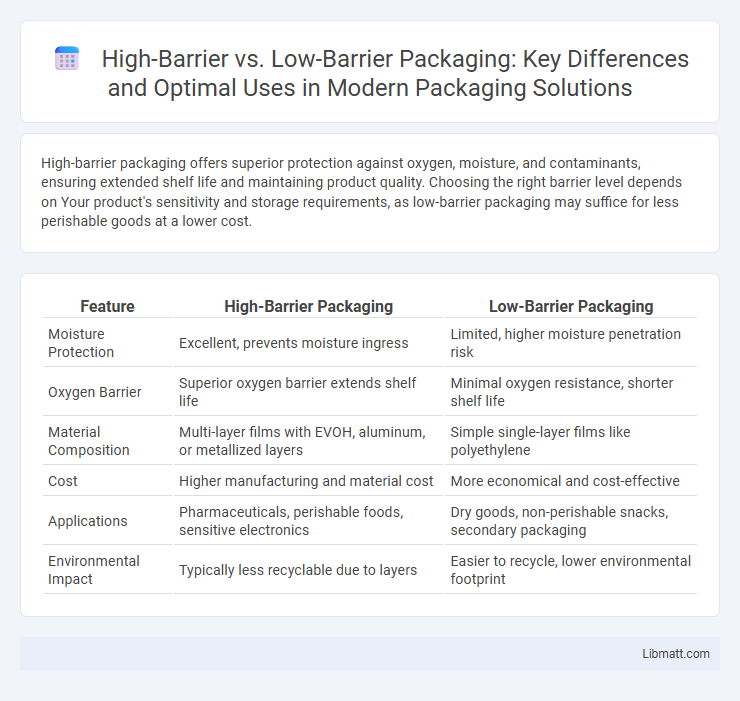

High-barrier packaging offers superior protection against oxygen, moisture, and contaminants, ensuring extended shelf life and maintaining product quality. Choosing the right barrier level depends on Your product's sensitivity and storage requirements, as low-barrier packaging may suffice for less perishable goods at a lower cost.

Table of Comparison

| Feature | High-Barrier Packaging | Low-Barrier Packaging |

|---|---|---|

| Moisture Protection | Excellent, prevents moisture ingress | Limited, higher moisture penetration risk |

| Oxygen Barrier | Superior oxygen barrier extends shelf life | Minimal oxygen resistance, shorter shelf life |

| Material Composition | Multi-layer films with EVOH, aluminum, or metallized layers | Simple single-layer films like polyethylene |

| Cost | Higher manufacturing and material cost | More economical and cost-effective |

| Applications | Pharmaceuticals, perishable foods, sensitive electronics | Dry goods, non-perishable snacks, secondary packaging |

| Environmental Impact | Typically less recyclable due to layers | Easier to recycle, lower environmental footprint |

Introduction to Packaging Barriers

High-barrier packaging materials provide superior protection against moisture, oxygen, and other environmental factors, extending product shelf life and preserving quality in pharmaceuticals and food industries. Low-barrier packaging offers minimal resistance to gas and vapor transmission, often used for products with shorter shelf life or lower sensitivity to environmental conditions. The choice between high- and low-barrier packaging depends on product requirements, cost considerations, and desired longevity.

Defining High-Barrier Packaging

High-barrier packaging uses advanced materials like multi-layer films and metalized foils to prevent oxygen, moisture, and light from contaminating or degrading products. This type of packaging is essential for extending the shelf life of sensitive goods such as pharmaceuticals, food, and electronics by providing superior protection against environmental factors. Your choice of high-barrier packaging ensures maximum product preservation and quality retention throughout distribution and storage.

Understanding Low-Barrier Packaging

Low-barrier packaging allows higher permeability to moisture, oxygen, and gases, making it suitable for products with a short shelf life or those stored in controlled environments. Common materials include polyethylene and polypropylene, which are cost-effective and recyclable but provide limited protection against external contaminants. This packaging type is ideal for items like bakery goods or fresh produce where breathability is essential to maintain quality.

Key Material Differences

High-barrier packaging utilizes materials such as EVOH (ethylene vinyl alcohol), aluminum foil, and metalized films to provide excellent protection against oxygen, moisture, and light, significantly extending product shelf life. Low-barrier packaging commonly features materials like polyethylene (PE), polypropylene (PP), and non-coated PET, which offer limited resistance to gas and moisture permeation, making them suitable for short-term or less sensitive food products. The difference in barrier properties arises from the molecular structure and coating technologies applied, where high-barrier layers create dense, impermeable barriers compared to the more porous and permeable nature of low-barrier polymer films.

Performance in Product Protection

High-barrier packaging offers superior protection by preventing oxygen, moisture, and contaminants from compromising product integrity, making it ideal for sensitive items such as pharmaceuticals and food with extended shelf life. Low-barrier packaging provides minimal resistance to external elements, suitable for products with short-term use or lower sensitivity. The choice between high-barrier and low-barrier packaging directly impacts product freshness, shelf stability, and overall quality retention.

Applications of High-Barrier Packaging

High-barrier packaging is essential for preserving perishable food products, pharmaceuticals, and electronics by providing superior protection against moisture, oxygen, and contaminants. It is widely used in the food industry for packaging snacks, dairy, and ready-to-eat meals to extend shelf life and maintain product quality. High-barrier films and laminates are also critical in pharmaceutical packaging to ensure sterility and stability of medications.

Uses of Low-Barrier Packaging

Low-barrier packaging is primarily used for products with short shelf lives or those that do not require protection from moisture, oxygen, or light, such as fresh produce, bakery items, and chilled foods. It is favored in applications where cost-efficiency and breathability are important, allowing for natural respiration and preventing spoilage. This type of packaging is commonly made from materials like polyethylene (PE) and polypropylene (PP), which provide minimal resistance to gas and vapor transmission.

Cost Considerations

High-barrier packaging typically incurs higher costs due to advanced materials and multi-layer constructions designed to protect sensitive products from moisture, oxygen, and contaminants. Low-barrier packaging is more cost-effective but offers limited protection, making it suitable for less perishable goods or shorter shelf lives. Your choice depends on balancing budget constraints with the required preservation level to ensure product quality and reduce waste.

Environmental Impact and Sustainability

High-barrier packaging significantly reduces oxygen and moisture transmission, extending product shelf life and minimizing food waste, which contributes to environmental sustainability. Low-barrier packaging, while often more recyclable and made from fewer resources, tends to have shorter product protection periods, potentially increasing waste and carbon footprint over time. Selecting high-barrier packaging materials with recyclable or biodegradable properties offers a balanced approach towards reducing environmental impact while maintaining product integrity.

Choosing the Right Packaging Solution

High-barrier packaging materials provide superior protection against oxygen, moisture, and light, extending product shelf life and preserving freshness for sensitive items like pharmaceuticals, food, and electronics. Low-barrier packaging is cost-effective and suitable for products with shorter shelf life or less sensitivity, such as dry goods or bulk items. Selecting the right packaging solution depends on balancing product preservation requirements, budget constraints, and environmental impact considerations.

High-barrier packaging vs low-barrier packaging Infographic

libmatt.com

libmatt.com