Gravure printing offers superior image quality and durability, making it ideal for high-volume jobs with detailed graphics, while offset printing provides faster turnaround and cost-efficiency for medium to large print runs. Understanding your project's specific needs will help determine whether gravure's precision or offset's versatility best suits Your printing requirements.

Table of Comparison

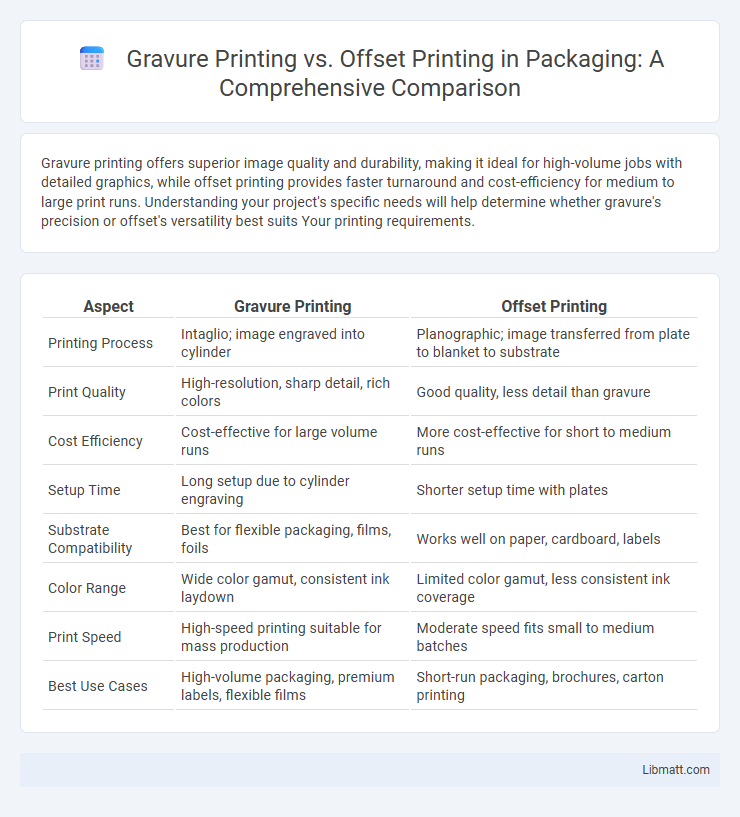

| Aspect | Gravure Printing | Offset Printing |

|---|---|---|

| Printing Process | Intaglio; image engraved into cylinder | Planographic; image transferred from plate to blanket to substrate |

| Print Quality | High-resolution, sharp detail, rich colors | Good quality, less detail than gravure |

| Cost Efficiency | Cost-effective for large volume runs | More cost-effective for short to medium runs |

| Setup Time | Long setup due to cylinder engraving | Shorter setup time with plates |

| Substrate Compatibility | Best for flexible packaging, films, foils | Works well on paper, cardboard, labels |

| Color Range | Wide color gamut, consistent ink laydown | Limited color gamut, less consistent ink coverage |

| Print Speed | High-speed printing suitable for mass production | Moderate speed fits small to medium batches |

| Best Use Cases | High-volume packaging, premium labels, flexible films | Short-run packaging, brochures, carton printing |

Introduction to Gravure and Offset Printing

Gravure printing uses a rotary press with engraved cylinders to transfer ink onto paper, excelling in high-volume, high-quality printing such as magazines and packaging. Offset printing employs a plate-based system where the inked image is transferred (offset) to a rubber blanket and then to the printing surface, ideal for large runs of newspapers, brochures, and books. Both methods offer distinct advantages in resolution, speed, and cost-efficiency depending on print job requirements and materials used.

Overview of Gravure Printing Process

Gravure printing involves engraving an image onto a cylinder, where the recessed cells hold the ink transferred directly to the substrate, allowing for high-quality, continuous-tone images. This process excels in producing detailed images with rich colors, making it ideal for large-volume printing such as magazines, packaging, and wallpaper. Gravure printing offers precise color consistency and fast production speeds, especially compared to offset printing's indirect method using rubber blankets.

How Offset Printing Works

Offset printing operates by transferring an inked image from a metal plate to a rubber blanket, then onto the printing surface, enabling high-quality, consistent prints. The process uses a water-based system where oil and water repel each other, ensuring only the inked areas adhere to the plate. This method is ideal for large-volume production, offering precise color control and sharp image detail.

Key Differences Between Gravure and Offset Printing

Gravure printing utilizes engraved cylinders to transfer ink directly onto the substrate, offering high-quality, consistent images ideal for large-volume runs, while offset printing employs a rubber blanket to transfer ink from plates, making it cost-effective for shorter runs with sharp, detailed results. Gravure excels in printing on non-porous surfaces like plastic and foil, whereas offset printing is preferred for paper products due to its versatility and faster setup times. The primary differences lie in image transfer methods, cost efficiency relative to print volume, and substrate compatibility.

Print Quality Comparison: Gravure vs Offset

Gravure printing delivers superior print quality with rich color depth and sharp detail, ideal for high-volume production of magazines and packaging. Offset printing offers excellent image clarity and color accuracy but may lack the continuous-tone quality of gravure, making it suitable for brochures and books. Gravure excels in reproducing fine lines and gradients, while offset provides efficient, cost-effective printing for moderate runs.

Cost Analysis: Gravure vs Offset Printing

Gravure printing involves higher initial cylinder fabrication costs compared to offset printing, making it more suitable for large-volume production runs to amortize expenses. Offset printing offers lower setup costs and faster turnaround times, which benefit short to medium print runs by reducing overall expenses. Cost efficiency in gravure improves with volume due to durable cylinders, while offset remains economical for diverse, smaller batch jobs with frequent design changes.

Suitable Applications for Gravure Printing

Gravure printing is ideal for high-volume production runs such as packaging, wallpaper, and magazines, where consistent image quality and fine detail are crucial. This method excels in printing on flexible substrates like plastic films and foils, making it popular for food wrappers, labels, and decorative laminates. Its ability to deliver rich, vibrant colors and durable prints supports extensive commercial and industrial printing applications.

Ideal Uses for Offset Printing

Offset printing excels in producing high-quality, consistent prints for large volume projects such as books, magazines, brochures, and newspapers due to its cost-efficiency and fast production speed. Your business benefits from offset printing when requiring sharp image reproduction and color accuracy on various paper types, making it ideal for marketing materials and professional publications. This method offers superior detail and quick turnaround, perfect for offset print runs exceeding thousands of copies.

Environmental Impact of Gravure and Offset Printing

Gravure printing typically uses solvent-based inks, which can release volatile organic compounds (VOCs) contributing to air pollution, whereas offset printing often employs water-based or soy-based inks, resulting in lower VOC emissions and reduced environmental impact. The energy consumption in gravure printing is generally higher due to the drying process required for solvent-based inks, while offset printing is more energy-efficient with faster setup and press speeds. Your choice between gravure and offset printing can significantly affect your environmental footprint, especially if sustainable materials and processes are a priority.

Choosing the Right Printing Method for Your Project

Gravure printing delivers superior image quality and is ideal for high-volume projects requiring vibrant color consistency on flexible packaging and magazines. Offset printing offers cost-effective precision for medium to large runs, excelling in detailed text and sharp graphics on paper-based materials. Evaluate project volume, substrate type, and print quality needs to determine the most efficient and economical printing method.

Gravure printing vs offset printing Infographic

libmatt.com

libmatt.com