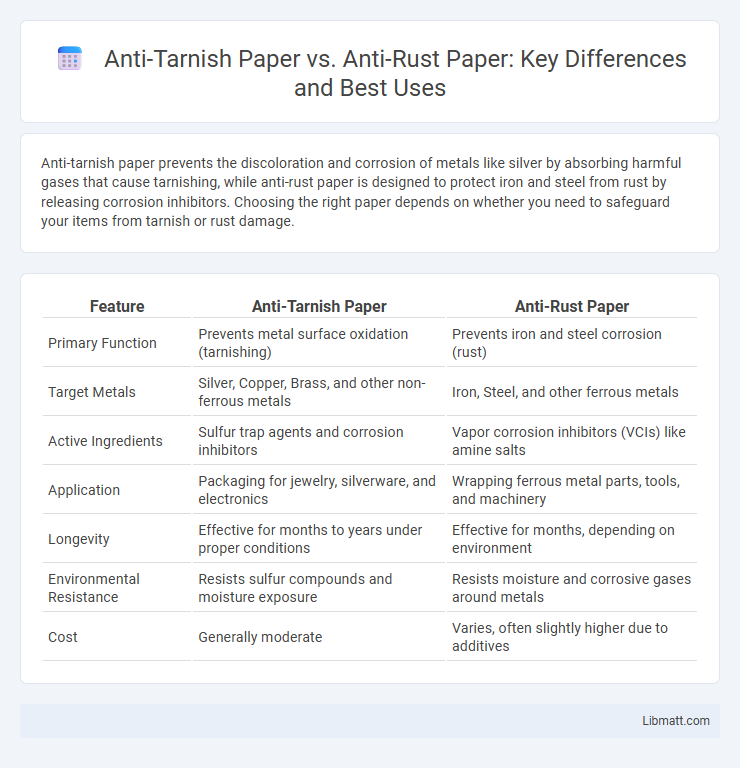

Anti-tarnish paper prevents the discoloration and corrosion of metals like silver by absorbing harmful gases that cause tarnishing, while anti-rust paper is designed to protect iron and steel from rust by releasing corrosion inhibitors. Choosing the right paper depends on whether you need to safeguard your items from tarnish or rust damage.

Table of Comparison

| Feature | Anti-Tarnish Paper | Anti-Rust Paper |

|---|---|---|

| Primary Function | Prevents metal surface oxidation (tarnishing) | Prevents iron and steel corrosion (rust) |

| Target Metals | Silver, Copper, Brass, and other non-ferrous metals | Iron, Steel, and other ferrous metals |

| Active Ingredients | Sulfur trap agents and corrosion inhibitors | Vapor corrosion inhibitors (VCIs) like amine salts |

| Application | Packaging for jewelry, silverware, and electronics | Wrapping ferrous metal parts, tools, and machinery |

| Longevity | Effective for months to years under proper conditions | Effective for months, depending on environment |

| Environmental Resistance | Resists sulfur compounds and moisture exposure | Resists moisture and corrosive gases around metals |

| Cost | Generally moderate | Varies, often slightly higher due to additives |

Introduction to Anti-Tarnish and Anti-Rust Papers

Anti-tarnish paper is designed primarily to prevent oxidation and discoloration of metals such as silver by releasing corrosion inhibitors that neutralize sulfur compounds and moisture in the environment. Anti-rust paper, on the other hand, targets ferrous metals by emitting volatile corrosion inhibitors (VCIs) that protect steel and iron surfaces from rust and corrosion during storage and shipping. Both types of papers are essential in metal preservation, utilizing chemical agents that create protective atmospheres to extend the lifespan of valuable metal products.

Understanding the Science Behind Anti-Tarnish Paper

Anti-tarnish paper works by releasing sulfur-absorbing compounds that prevent silver and other metals from reacting with sulfur-containing gases, thus inhibiting the tarnishing process. Unlike anti-rust paper, which targets moisture and iron oxidation to prevent rust, anti-tarnish paper specifically neutralizes volatile sulfur compounds to maintain the metal's shine. Your choice between these materials depends on whether you need protection against tarnish or rust for your metal items.

How Anti-Rust Paper Works: Key Mechanisms

Anti-rust paper works by releasing volatile corrosion inhibitors (VCIs) that form a protective molecular layer on metal surfaces, preventing oxidation and rust formation. These inhibitors create a micro-environment that stabilizes the metal's surface, effectively blocking moisture and corrosive agents. The paper's composition allows for controlled release of these compounds, ensuring extended protection during storage and transport.

Key Differences Between Anti-Tarnish and Anti-Rust Papers

Anti-tarnish paper primarily protects silver and other precious metals from oxidation and discoloration by releasing corrosion inhibitors that prevent surface degradation. In contrast, anti-rust paper is designed to protect ferrous metals like steel and iron from rust by emitting volatile corrosion inhibitors (VCIs) that prevent moisture-induced oxidation. The key difference lies in their targeted metal types--anti-tarnish paper is formulated for non-ferrous metals, while anti-rust paper specifically prevents corrosion on ferrous metals.

Common Materials Protected by Anti-Tarnish Paper

Anti-tarnish paper is primarily used to protect silver, copper, and brass from discoloration caused by oxidation and sulfur compounds, making it essential for preserving jewelry, silverware, and musical instruments. Your valuable items made of these metals benefit from this specialized paper that absorbs harmful gases, extending their shine and quality. In contrast, anti-rust paper is designed to prevent corrosion in ferrous metals like iron and steel, typically found in tools, machinery, and automotive parts.

Applications of Anti-Rust Paper in Various Industries

Anti-rust paper is extensively used in automotive, electronics, and machinery industries to protect metal parts from corrosion during storage and transportation. This paper releases vapor corrosion inhibitors (VCIs) that form a protective layer on metal surfaces, preventing rust and prolonging product lifespan. Industries such as aerospace, defense, and manufacturing rely on anti-rust paper for effective corrosion control in complex metal components and heavy equipment.

Benefits of Choosing Anti-Tarnish Paper

Anti-tarnish paper prevents oxidation and discoloration of silver and other precious metals by absorbing airborne sulfur compounds, ensuring your jewelry and silverware remain shiny and pristine. Unlike anti-rust paper, which targets protection against moisture and corrosion on ferrous metals, anti-tarnish paper is specifically designed to maintain the aesthetic appeal of non-ferrous metals without introducing moisture. Choosing anti-tarnish paper protects your valuable items from tarnish-related damage, extending their lifespan and preserving their value.

Advantages of Using Anti-Rust Paper

Anti-rust paper offers superior protection by releasing corrosion inhibitors that prevent oxidation on metal surfaces during storage and shipping. Its ability to absorb moisture and block salt and other contaminants makes it highly effective for preserving tools, machine parts, and electronic components. Compared to anti-tarnish paper, anti-rust paper is specifically designed to prevent rust formation, providing long-term durability in harsh environments.

Environmental Considerations: Anti-Tarnish vs Anti-Rust Paper

Anti-tarnish paper uses environmentally friendly compounds that prevent oxidation on silver and other metals without releasing harmful chemicals, making it a sustainable choice for jewelry and silverware protection. Anti-rust paper contains corrosion inhibitors designed to protect ferrous metals from rust, often incorporating biodegradable materials to minimize environmental impact. Both papers reduce the need for harsh chemical treatments and contribute to eco-conscious metal preservation practices.

Selecting the Right Protection: Anti-Tarnish or Anti-Rust Paper?

Choosing between anti-tarnish paper and anti-rust paper depends on the type of metal and environmental conditions involved. Anti-tarnish paper is specially coated to prevent oxidation and discoloration on metals like silver and copper, while anti-rust paper contains inhibitors that protect ferrous metals from corrosion caused by moisture. Evaluating metal composition and exposure to humidity ensures optimal protection and longevity of the items.

Anti-tarnish paper vs anti-rust paper Infographic

libmatt.com

libmatt.com