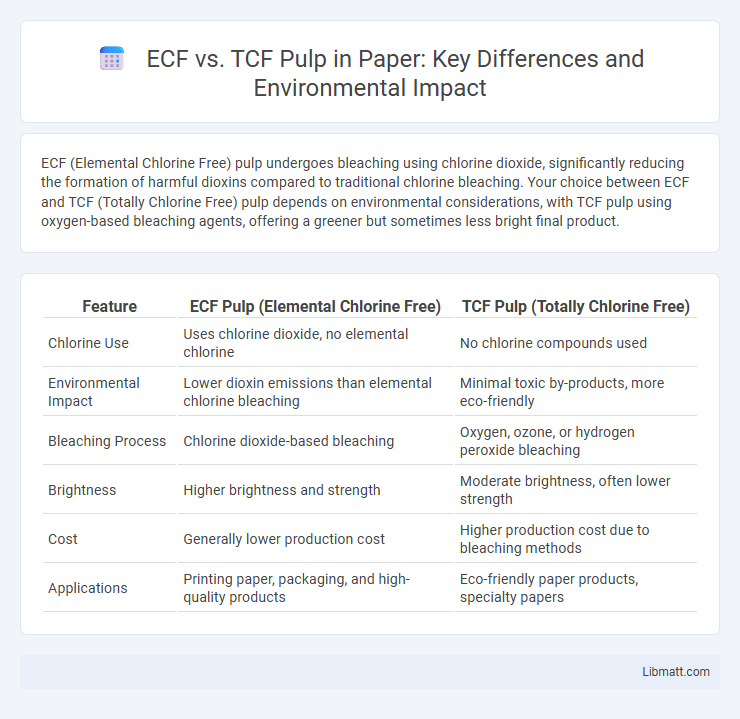

ECF (Elemental Chlorine Free) pulp undergoes bleaching using chlorine dioxide, significantly reducing the formation of harmful dioxins compared to traditional chlorine bleaching. Your choice between ECF and TCF (Totally Chlorine Free) pulp depends on environmental considerations, with TCF pulp using oxygen-based bleaching agents, offering a greener but sometimes less bright final product.

Table of Comparison

| Feature | ECF Pulp (Elemental Chlorine Free) | TCF Pulp (Totally Chlorine Free) |

|---|---|---|

| Chlorine Use | Uses chlorine dioxide, no elemental chlorine | No chlorine compounds used |

| Environmental Impact | Lower dioxin emissions than elemental chlorine bleaching | Minimal toxic by-products, more eco-friendly |

| Bleaching Process | Chlorine dioxide-based bleaching | Oxygen, ozone, or hydrogen peroxide bleaching |

| Brightness | Higher brightness and strength | Moderate brightness, often lower strength |

| Cost | Generally lower production cost | Higher production cost due to bleaching methods |

| Applications | Printing paper, packaging, and high-quality products | Eco-friendly paper products, specialty papers |

Introduction to ECF and TCF Pulp

Elemental Chlorine Free (ECF) pulp is produced using chlorine dioxide for bleaching, minimizing environmental impact while maintaining high pulp quality and brightness. Totally Chlorine Free (TCF) pulp avoids chlorine compounds entirely, relying on oxygen, ozone, or hydrogen peroxide, resulting in a more eco-friendly but typically less bright pulp. Understanding the differences between ECF and TCF pulp helps you choose the right pulp type for your environmental goals and product quality requirements.

What is ECF (Elemental Chlorine Free) Pulp?

ECF (Elemental Chlorine Free) pulp is produced using chlorine dioxide instead of elemental chlorine during the bleaching process, significantly reducing the formation of harmful dioxins and chlorinated organic compounds. This method ensures a cleaner, more environmentally friendly pulp suitable for high-quality paper production while maintaining brightness and strength. Choosing ECF pulp supports sustainable forestry practices and reduces your ecological footprint in paper consumption.

What is TCF (Totally Chlorine Free) Pulp?

TCF (Totally Chlorine Free) pulp is produced using oxygen, ozone, or hydrogen peroxide bleaching methods without any chlorine compounds, resulting in minimal environmental impact. This pulp type ensures reduced release of harmful chlorinated organic compounds into water bodies compared to ECF (Elemental Chlorine Free) pulp. Choosing TCF pulp supports your commitment to sustainable paper production with a lower ecological footprint.

Key Differences Between ECF and TCF Pulp

ECF (Elemental Chlorine Free) pulp is bleached using chlorine dioxide, minimizing harmful dioxin formation while maintaining high brightness and strength. TCF (Totally Chlorine Free) pulp uses oxygen, ozone, or hydrogen peroxide for bleaching, ensuring zero chlorine compounds but often resulting in lower brightness. Your choice between ECF and TCF pulp depends on balancing environmental impact, product quality, and processing costs.

Environmental Impact of ECF vs TCF Pulp

Elemental Chlorine Free (ECF) pulp production uses chlorine dioxide, significantly reducing the release of chlorinated organic compounds compared to traditional chlorine methods, yet it still generates some chlorinated byproducts. Totally Chlorine Free (TCF) pulp employs oxygen-based bleaching agents like ozone and hydrogen peroxide, resulting in minimal toxic effluent and lower environmental pollution. TCF processes typically exhibit reduced ecotoxicity and biodegradability impacts on aquatic ecosystems, making them a more environmentally sustainable choice.

Bleaching Processes in ECF and TCF Pulp Production

Elemental Chlorine Free (ECF) pulp bleaching relies on chlorine dioxide as the primary bleaching agent, significantly reducing dioxin formation compared to traditional elemental chlorine. Totally Chlorine Free (TCF) pulp bleaching utilizes oxygen, ozone, hydrogen peroxide, and enzymes to achieve high brightness without any chlorine compounds, making it more environmentally sustainable. Both processes aim to meet industry standards for brightness and strength while minimizing ecological impact, with ECF being more common due to balanced cost and environmental benefits.

Cost Comparison: ECF vs TCF Pulp

ECF (Elemental Chlorine Free) pulp typically incurs lower production costs than TCF (Totally Chlorine Free) pulp due to less complex bleaching processes and widely available chemicals. Your choice impacts overall expenses, as TCF pulp requires more energy-intensive and costly oxygen-based bleaching agents to achieve comparable brightness without chlorine. Evaluating cost differences helps optimize budget allocation while meeting environmental and quality standards.

Product Quality and Performance: ECF vs TCF

ECF (Elemental Chlorine-Free) pulp delivers higher product quality with superior brightness and improved strength compared to TCF (Totally Chlorine-Free) pulp, making it ideal for applications requiring high-performance paper products. TCF pulp, produced without chlorine compounds, offers better environmental credentials but may have slightly lower brightness and durability. Your choice depends on prioritizing either optimal product performance or environmental impact in pulp production.

Market Trends and Demand for ECF and TCF Pulp

Market trends indicate steady growth in demand for Elemental Chlorine Free (ECF) pulp due to its cost-effectiveness and strong bleaching properties, dominating global pulp production. Totally Chlorine Free (TCF) pulp is gaining market traction as sustainability and environmental regulations drive demand for chlorine-free products that reduce harmful emissions. Your choice between ECF and TCF pulp should consider regional market preferences, regulatory requirements, and consumer demand for eco-friendly paper products.

Choosing the Right Pulp: ECF or TCF?

Choosing between ECF (Elemental Chlorine-Free) and TCF (Totally Chlorine-Free) pulp depends on your sustainability goals and product requirements. ECF pulp offers high brightness and excellent strength with minimal environmental impact due to its use of chlorine dioxide, while TCF pulp eliminates chlorine compounds entirely, making it ideal for eco-sensitive applications despite slightly lower brightness. Your decision should balance environmental responsibility and performance needs to select the most suitable pulp for your project.

ECF vs TCF pulp Infographic

libmatt.com

libmatt.com