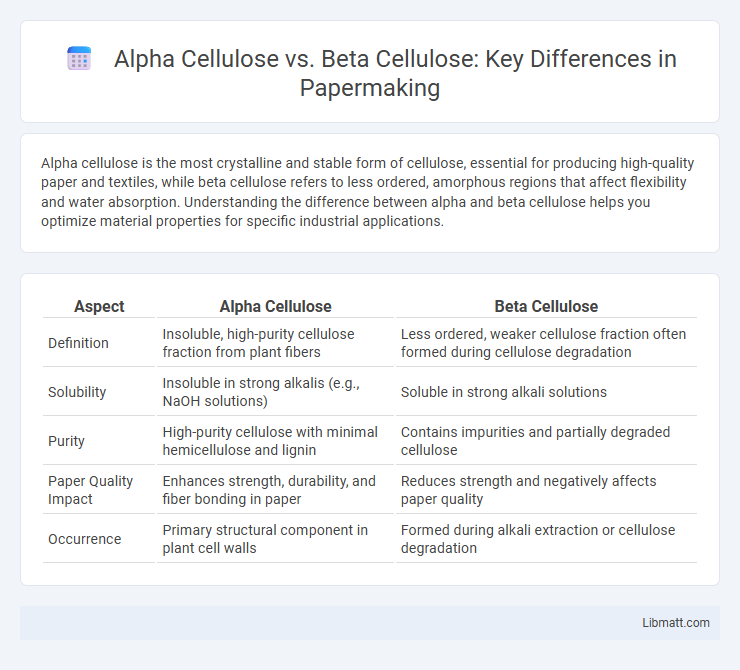

Alpha cellulose is the most crystalline and stable form of cellulose, essential for producing high-quality paper and textiles, while beta cellulose refers to less ordered, amorphous regions that affect flexibility and water absorption. Understanding the difference between alpha and beta cellulose helps you optimize material properties for specific industrial applications.

Table of Comparison

| Aspect | Alpha Cellulose | Beta Cellulose |

|---|---|---|

| Definition | Insoluble, high-purity cellulose fraction from plant fibers | Less ordered, weaker cellulose fraction often formed during cellulose degradation |

| Solubility | Insoluble in strong alkalis (e.g., NaOH solutions) | Soluble in strong alkali solutions |

| Purity | High-purity cellulose with minimal hemicellulose and lignin | Contains impurities and partially degraded cellulose |

| Paper Quality Impact | Enhances strength, durability, and fiber bonding in paper | Reduces strength and negatively affects paper quality |

| Occurrence | Primary structural component in plant cell walls | Formed during alkali extraction or cellulose degradation |

Introduction to Cellulose: Alpha vs Beta

Alpha cellulose represents the high-molecular-weight, crystalline portion of cellulose that is insoluble in alkali and forms the structural framework of plant cell walls. Beta cellulose, often considered the alkali-soluble fraction, consists of lower molecular weight polysaccharides that are more amorphous and less stable. Understanding the distinction between alpha and beta cellulose is critical for applications in papermaking, textile manufacturing, and biofuel production due to their differing chemical reactivity and physical properties.

Structural Differences Between Alpha and Beta Cellulose

Alpha cellulose consists of linear chains of glucose molecules linked by b-1,4-glycosidic bonds forming a crystalline structure with strong hydrogen bonding, which provides higher mechanical strength and resistance to solvents. Beta cellulose, instead, contains shorter, less ordered chains with fewer hydrogen bonds, resulting in an amorphous structure that is more soluble and less stable. The structural difference lies in the molecular arrangement and degree of polymerization, with alpha cellulose exhibiting a tightly packed, crystalline lattice, while beta cellulose shows a more disorganized, amorphous configuration.

Sources and Extraction Methods

Alpha cellulose is primarily extracted from high-purity wood pulp through chemical treatments like kraft or sulfite processes, making it ideal for producing high-strength paper and textiles. Beta cellulose, found in lower amounts in plant cell walls, is typically isolated via milder extraction methods that preserve its less ordered structure, often from non-wood fibers such as hemp or flax. Understanding these distinct sources and extraction techniques helps you select the appropriate cellulose type for your specific industrial or research applications.

Chemical Properties and Composition

Alpha cellulose is a pure, high-molecular-weight polymer consisting primarily of linear chains of D-glucose units linked by b-1,4-glycosidic bonds, exhibiting strong hydrogen bonding and crystalline structure. Beta cellulose, in contrast, contains shorter polymer chains and amorphous regions with partial hydrolysis products, including hemicelluloses and lignin impurities, resulting in lower molecular weight and less crystalline order. Chemically, alpha cellulose is more resistant to chemical degradation and solvents due to its high degree of polymerization and purity, while beta cellulose is more reactive and less stable in alkali or acidic conditions.

Applications in Industry and Research

Alpha cellulose, a highly pure and crystalline form of cellulose, is extensively used in the production of high-strength paper, textiles, and bio-based composites due to its superior mechanical properties and chemical stability. Beta cellulose, being less crystalline and more reactive, finds applications in biofuel production, enzymatic hydrolysis studies, and as a substrate in biodegradable materials research. Industrial processes leverage alpha cellulose for durability and quality, while beta cellulose is pivotal in research focused on cellulose degradation and conversion into renewable energy sources.

Alpha Cellulose: Key Features and Benefits

Alpha cellulose, the highest purity form of cellulose, consists of long chains of glucose molecules tightly bound in a crystalline structure, providing exceptional strength and durability. Its resistance to chemicals, moisture, and microbial degradation makes it ideal for high-quality paper production, textiles, and biodegradable materials. Compared to beta cellulose, alpha cellulose offers superior mechanical properties and stability, ensuring enhanced performance in industrial applications.

Beta Cellulose: Characteristics and Uses

Beta cellulose is a less common form of cellulose characterized by its different crystalline structure compared to alpha cellulose, resulting in lower purity and solubility. It exhibits a more rigid and compact molecular arrangement, making it useful in applications requiring enhanced strength and stability, such as in composite materials and specialty papers. Understanding the specific properties of beta cellulose can help you select the right cellulose type for industrial processes or product development involving improved mechanical performance.

Comparison Table: Alpha vs Beta Cellulose

Alpha cellulose consists of long, pure cellulose chains that provide high strength and stability, making it ideal for paper and textile manufacturing, while beta cellulose is a less pure, intermediate form with shorter chains and lower crystallinity. Alpha cellulose boasts superior resistance to chemical and enzymatic degradation compared to beta cellulose, which is more susceptible to breakdown during processing. You can distinguish these forms by their molecular weight, crystallinity, and biological resistance, essential factors when selecting cellulose for industrial applications.

Role in Environmental Sustainability

Alpha cellulose, with its high purity and resistance to chemical degradation, plays a crucial role in environmental sustainability by offering biodegradable and renewable alternatives to synthetic polymers, thereby reducing plastic waste. Beta cellulose, less processed and more amorphous, contributes to soil health and carbon sequestration when present in plant residues, enhancing natural ecosystem functions. Both forms support sustainable material cycles through their distinct biodegradability and role in maintaining ecological balance.

Future Trends in Cellulose Utilization

Future trends in cellulose utilization emphasize enhancing alpha cellulose extraction due to its superior purity and mechanical strength, making it ideal for high-performance bioplastics and nanocellulose production. Advances in enzymatic and chemical processing aim to efficiently separate beta cellulose, unlocking its potential in biofuels and sustainable packaging materials. Your ability to leverage these innovations could drive the development of eco-friendly products with improved functionality and reduced environmental impact.

Alpha cellulose vs beta cellulose Infographic

libmatt.com

libmatt.com