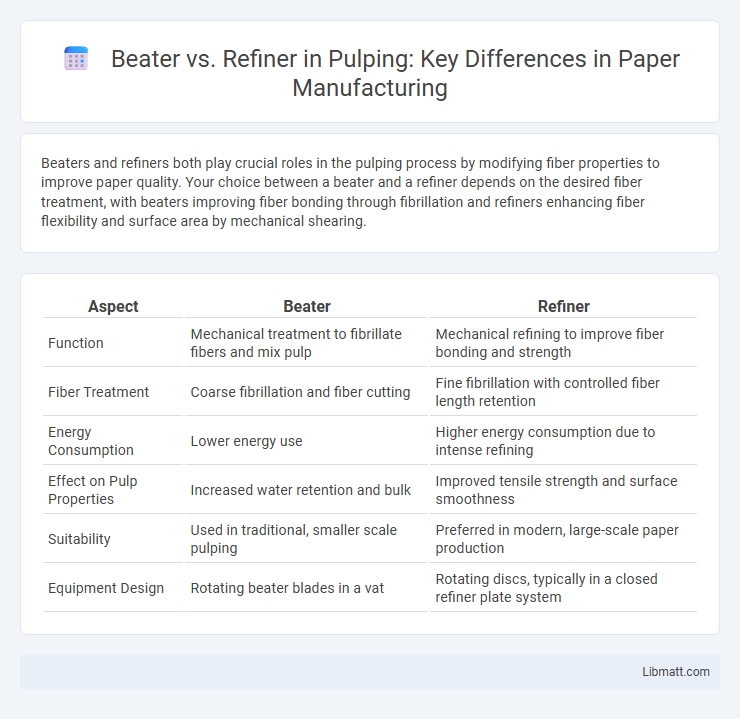

Beaters and refiners both play crucial roles in the pulping process by modifying fiber properties to improve paper quality. Your choice between a beater and a refiner depends on the desired fiber treatment, with beaters improving fiber bonding through fibrillation and refiners enhancing fiber flexibility and surface area by mechanical shearing.

Table of Comparison

| Aspect | Beater | Refiner |

|---|---|---|

| Function | Mechanical treatment to fibrillate fibers and mix pulp | Mechanical refining to improve fiber bonding and strength |

| Fiber Treatment | Coarse fibrillation and fiber cutting | Fine fibrillation with controlled fiber length retention |

| Energy Consumption | Lower energy use | Higher energy consumption due to intense refining |

| Effect on Pulp Properties | Increased water retention and bulk | Improved tensile strength and surface smoothness |

| Suitability | Used in traditional, smaller scale pulping | Preferred in modern, large-scale paper production |

| Equipment Design | Rotating beater blades in a vat | Rotating discs, typically in a closed refiner plate system |

Introduction to Pulping Processes

Beaters and refiners are essential equipment in mechanical pulping processes, crucial for fiber separation and modification. Beaters primarily work by beating and fibrillating wood chips to enhance fiber bonding and paper strength, while refiners use rotating discs to apply shear forces that improve fiber quality and pulp consistency. Understanding the distinct roles of beaters and refiners enables optimization of pulp properties for various paper products.

Understanding Beaters: Definition and Function

Beaters are mechanical devices used in pulping to refine and fibrillate fibers, improving fiber bonding and paper strength. They operate by applying pressure and shear forces to pulp fibers, enhancing their surface characteristics and sludge removal. Understanding your beater's role is crucial for optimizing fiber treatment and achieving desired paper quality in the pulping process.

Refiners Explained: Role in Pulping

Refiners play a critical role in pulping by mechanically treating fibers to improve their bonding ability, which enhances paper strength and quality. Unlike beaters that macerate fibers through repeated pounding, refiners use rotating discs to fibrillate and soften the pulp while controlling fiber length and consistency. Your paper production benefits from refiners by achieving optimized fiber properties that increase sheet formation efficiency and surface smoothness.

Key Differences Between Beater and Refiner

Beater and refiner are essential machines in the pulping process, primarily differing in their operation and impact on fiber quality. A beater agitates pulp fibers in water, promoting fibrillation and enhancing fiber bonding, while a refiner uses rotating discs to mechanically treat fibers, improving fiber flexibility and strength. Understanding these distinctions can help you optimize pulp characteristics for specific paper production needs.

Mechanisms of Fiber Processing

Beatters mechanically treat wood fibers by crushing and fibrillating, enhancing fiber bonding through surface roughness and flexibility, which improves paper strength and printability. Refiners use disc plates to apply shear and compression forces, selectively delaminating fiber walls and increasing fiber swelling for better fiber bonding and sheet formation. Your choice between beater and refiner influences fiber characteristics, directly impacting pulp quality and paper performance.

Impact on Fiber Properties and Quality

Beaters in pulping mechanically treat fibers, improving fiber fibrillation and bonding potential but often causing fiber shortening and strength loss. Refiners apply controlled energy to individual fibers, enhancing fiber swelling, flexibility, and surface area while better preserving fiber length and tensile strength. The choice between beater and refiner processes significantly affects pulp quality, with refiners generally producing stronger, more uniform fibers suited for high-strength paper products.

Energy Consumption: Beater vs Refiner

Beaters generally consume less energy compared to refiners during the pulping process due to their simpler mechanical action aimed at fiber separation and cleaning. Refiners require higher energy input as they apply intensive mechanical forces to fibrillate fibers, improving pulp quality but increasing electricity usage significantly. Your choice between a beater and a refiner will impact overall energy costs and efficiency depending on the desired pulp characteristics.

Applications in the Pulp and Paper Industry

Beaters and refiners play crucial roles in the pulp and paper industry, each optimizing fiber treatment for specific applications. Beaters are primarily used in the initial fibrillation of pulp fibers, enhancing fiber bonding for printing and writing papers, while refiners further develop fiber properties by improving strength and uniformity in tissue and specialty papers. Understanding your production needs helps determine the best choice to achieve desired paper quality and performance.

Advantages and Limitations of Each Method

Beaters in pulping provide efficient fiber fibrillation and improved bonding properties, enhancing paper strength but can cause fiber damage and energy-intensive processing. Refiners offer controlled fiber treatment, producing uniform pulp quality and better drainage, yet they may result in lower fiber length and reduced tear strength. Your choice depends on balancing desired paper quality with energy consumption and fiber integrity.

Choosing the Right Equipment for Pulping

Choosing the right equipment for pulping depends on the desired fiber properties and production efficiency, where beaters excel at fibrillation and refining improves fiber flexibility and bonding. Beaters are preferable for mechanical pulping with high energy consumption and coarser fibers, while refiners offer better control in chemical pulping processes for smoother, stronger fibers. Your selection directly impacts pulp quality, energy use, and overall process cost efficiency.

beater vs refiner in pulping Infographic

libmatt.com

libmatt.com