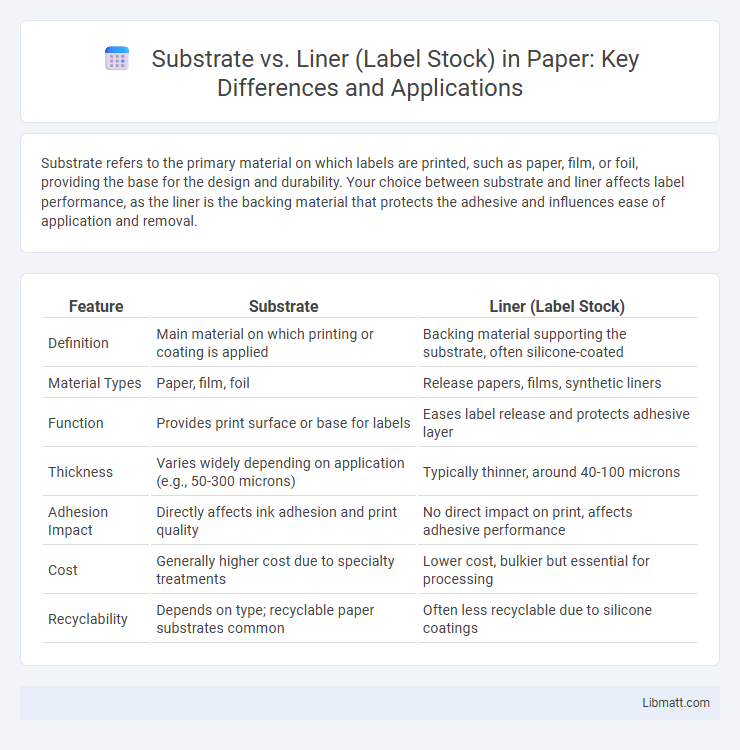

Substrate refers to the primary material on which labels are printed, such as paper, film, or foil, providing the base for the design and durability. Your choice between substrate and liner affects label performance, as the liner is the backing material that protects the adhesive and influences ease of application and removal.

Table of Comparison

| Feature | Substrate | Liner (Label Stock) |

|---|---|---|

| Definition | Main material on which printing or coating is applied | Backing material supporting the substrate, often silicone-coated |

| Material Types | Paper, film, foil | Release papers, films, synthetic liners |

| Function | Provides print surface or base for labels | Eases label release and protects adhesive layer |

| Thickness | Varies widely depending on application (e.g., 50-300 microns) | Typically thinner, around 40-100 microns |

| Adhesion Impact | Directly affects ink adhesion and print quality | No direct impact on print, affects adhesive performance |

| Cost | Generally higher cost due to specialty treatments | Lower cost, bulkier but essential for processing |

| Recyclability | Depends on type; recyclable paper substrates common | Often less recyclable due to silicone coatings |

Introduction to Substrates and Liners in Label Stock

Substrates and liners are essential components of label stock, where substrates serve as the primary surface for printing and adhesive application, while liners provide protective backing to maintain label integrity before use. Common substrates include paper, polypropylene, and polyester, each chosen based on durability, print quality, and application requirements. Your choice between substrate and liner materials impacts label performance, peelability, and overall product presentation in various industries.

Definition and Role of Substrate in Labels

The substrate in label stock refers to the base material onto which graphics, text, or adhesive are applied, serving as the foundation for the entire label structure. Common substrates include paper, polyester, polypropylene, and vinyl, each offering distinct durability, flexibility, and print quality characteristics tailored to various labeling needs. The substrate's role is critical in determining label performance, adhesion, and compatibility with printing methods, directly impacting the label's functionality and aesthetic appeal.

Understanding Liners in Label Stock Construction

Liners in label stock construction serve as the release-coated backing that allows labels to be easily peeled off during application. Common liner materials include silicone-coated paper and film, each offering specific benefits in terms of strength, flexibility, and cost-efficiency. The choice between paper and film liners affects label performance, shelf life, and suitability for various labeling machines and environments.

Key Differences Between Substrate and Liner

Substrate refers to the primary material on which labels are printed, such as paper, film, or foil, providing the visual and tactile surface of the label. The liner, typically a silicone-coated release paper or film, serves as a backing that protects the adhesive side of pressure-sensitive labels until application. Key differences include function--substrate forms the label face, while liner protects the adhesive--and material composition, with substrates designed for print quality and durability and liners optimized for easy release during dispensing.

Common Materials Used for Label Substrates

Label substrates commonly use materials such as paper, polypropylene, polyester, and vinyl, chosen for their durability, printability, and resistance to environmental factors. Paper substrates offer cost-effectiveness and ease of printing, while synthetic liners like silicone-coated polyester provide excellent release properties and dimensional stability. Polypropylene and polyester substrates enhance moisture resistance and longevity, making them suitable for various labeling applications across industries.

Typical Liner Materials and Their Properties

Typical liner materials in label stock include kraft paper, glassine, and polyethylene-coated paper, each offering distinct properties for different labeling needs. Kraft paper is known for its durability and high tensile strength, making it suitable for heavy-duty labels, while glassine provides smoothness and moisture resistance ideal for high-speed label application. Polyethylene-coated paper liners combine flexibility and moisture resistance, enhancing die-cutting performance and label release characteristics for various substrates.

Impact of Substrate Choice on Label Performance

The choice of substrate in label stock significantly impacts label durability, adhesion, and print quality, with materials like polypropylene offering superior moisture resistance and dimensional stability compared to traditional paper liners. Films such as PET substrates enhance flexibility and chemical resistance, making them ideal for labels exposed to harsh environments or requiring high clarity. Selecting the appropriate substrate ensures optimized label performance tailored to specific application needs, including environmental conditions and surface compatibility.

How Liners Affect Label Application and Waste

Liners in label stock significantly impact label application by providing a smooth release surface that ensures easy dispensing and precise placement, reducing misalignment and application errors. The material and thickness of the liner affect waste generation, as thicker or non-recyclable liners contribute to higher disposal volumes and environmental impact. Optimizing liner choice can improve your labeling efficiency and reduce waste management costs.

Selecting the Right Substrate and Liner for Your Needs

Choosing the right substrate and liner is essential for optimal label performance and durability. Substrates like paper, film, or synthetic materials each offer unique benefits depending on exposure conditions, while liners such as silicone-coated or glassine impact ease of label dispensing and adhesion reliability. Your selection should consider environmental factors, surface compatibility, and application requirements to ensure long-lasting, high-quality label results.

Environmental Considerations: Substrate vs. Liner

Substrate materials in label stock often emphasize sustainability through the use of recyclable or biodegradable fibers, reducing environmental impact compared to traditional liner materials, which are typically made from non-recyclable plastics or silicone-coated papers. Advances in linerless label technology further minimize waste by eliminating the need for a separate liner, significantly lowering material consumption and landfill contributions. Your choice between substrate and liner should prioritize eco-friendly properties, such as compostability and recyclability, to support greener packaging solutions and reduce your carbon footprint.

Substrate vs liner (label stock) Infographic

libmatt.com

libmatt.com