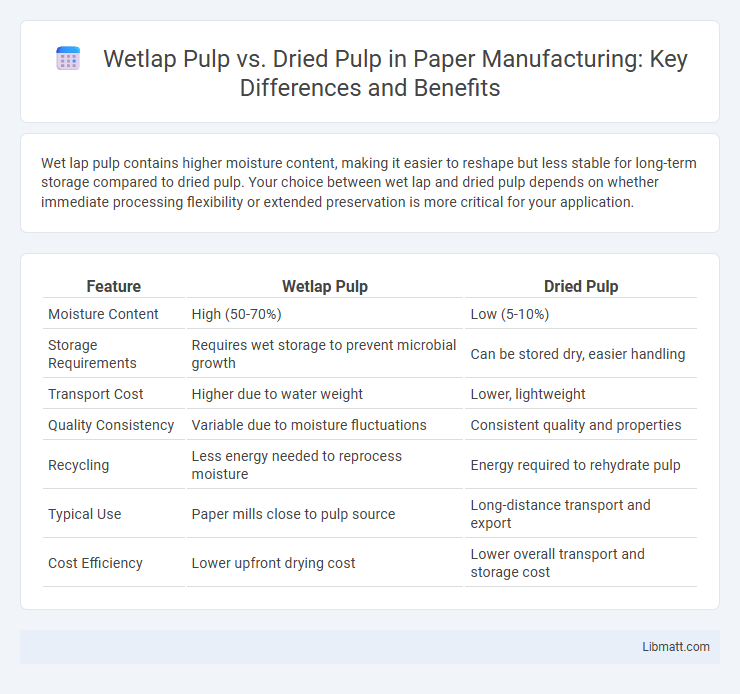

Wet lap pulp contains higher moisture content, making it easier to reshape but less stable for long-term storage compared to dried pulp. Your choice between wet lap and dried pulp depends on whether immediate processing flexibility or extended preservation is more critical for your application.

Table of Comparison

| Feature | Wetlap Pulp | Dried Pulp |

|---|---|---|

| Moisture Content | High (50-70%) | Low (5-10%) |

| Storage Requirements | Requires wet storage to prevent microbial growth | Can be stored dry, easier handling |

| Transport Cost | Higher due to water weight | Lower, lightweight |

| Quality Consistency | Variable due to moisture fluctuations | Consistent quality and properties |

| Recycling | Less energy needed to reprocess moisture | Energy required to rehydrate pulp |

| Typical Use | Paper mills close to pulp source | Long-distance transport and export |

| Cost Efficiency | Lower upfront drying cost | Lower overall transport and storage cost |

Introduction to Wetlap Pulp and Dried Pulp

Wetlap pulp, a type of chemical pulp, undergoes a refining process where fibers are fibrillated but remain wet, enhancing their bonding ability and strength in paper products. Dried pulp, in contrast, has been processed and dried, resulting in fibers that are less flexible and often used for different paper grades requiring stiffness and bulk. Understanding the differences between wetlap and dried pulp is essential for optimizing Your paper production for specific strength and texture requirements.

Understanding Wetlap Pulp: Definition and Process

Wetlap pulp, a semi-finished fiber product, is created through a wet pressing process that removes excess water from pulp sheets without fully drying them, preserving fiber flexibility and bonding properties. This stage occurs between pulp washing and drying in paper manufacturing, ensuring optimal fiber swelling for enhanced paper strength. Understanding wetlap pulp is essential for controlling quality and performance in the production of various paper grades.

What is Dried Pulp? Key Characteristics

Dried pulp refers to pulp material that has undergone a drying process to reduce moisture content, enhancing its shelf life and stability for transport and storage. Key characteristics include low moisture content (typically below 10%), reduced microbial activity, and improved handling properties compared to wetlap pulp. Your choice between wetlap and dried pulp impacts processing efficiency and final product quality in paper manufacturing.

Manufacturing Processes: Wetlap vs Dried Pulp

Wetlap pulp undergoes partial drying on a wetlap machine, which combines pressing and evaporation to produce sheets with higher moisture content, enhancing fiber bonding and softness. In contrast, dried pulp is fully dried through additional drying cylinders or ovens, resulting in lower moisture content, increased stiffness, and better shelf life for packaging and cardboard applications. The wetlap process offers energy efficiency by reducing drying time, while dried pulp provides durability and stability essential for end-product strength.

Quality Differences: Strength, Purity, and Performance

Wetlap pulp generally offers higher fiber strength and better bonding potential compared to dried pulp, enhancing the durability of the final paper product. The purity of wetlap pulp is often superior due to reduced exposure to contaminants during storage, resulting in improved performance in specialized paper applications. Your choice of wetlap versus dried pulp directly impacts product quality, influencing strength, purity, and overall manufacturing efficiency.

Environmental Impact and Sustainability Considerations

Wetlap pulp production consumes significantly more water and energy compared to dried pulp, leading to a higher environmental footprint. The drying process requires large amounts of thermal energy, increasing greenhouse gas emissions, whereas wetlap pulp's minimal drying reduces energy use but results in higher transportation emissions due to increased weight. Sustainable practices prioritize optimizing energy efficiency in drying and improving the logistics of wetlap pulp to minimize overall carbon emissions.

Cost Implications: Production and Transportation

Wetlap pulp production requires significant energy for drying, increasing manufacturing costs compared to dried pulp, which is already moisture-reduced and ready for use. Transportation expenses for wetlap pulp are higher due to its greater weight and volume, leading to increased fuel consumption and logistical challenges. Optimizing your supply chain by balancing the lower material cost of wetlap pulp against the elevated transportation and drying expenses is crucial for cost-effective pulp management.

End-Use Applications for Wetlap Pulp and Dried Pulp

Wetlap pulp offers superior fiber strength and bulk, making it ideal for high-quality printing papers, packaging materials, and specialty papers requiring durability and softness. Dried pulp, with its reduced moisture content, suits applications like absorbent hygiene products, tissue papers, and molded fiber packaging where rapid rehydration and consistency are essential. Your selection between wetlap and dried pulp depends on the specific performance requirements of the end-use product, balancing strength, absorbency, and processing efficiency.

Industry Trends and Market Demand

Wetlap pulp maintains higher moisture content, influencing energy use and storage costs in paper production, while dried pulp offers longer shelf life and easier transport, impacting supply chain decisions. The industry trend shows increasing preference for dried pulp due to advancements in drying technology and growing demand for high-quality, lightweight paper products. Your choice between wetlap and dried pulp will affect production efficiency and meet specific market demands driven by sustainability and cost-effectiveness.

Choosing the Right Pulp: Factors for Decision-Making

Choosing between wetlap pulp and dried pulp depends on factors such as storage capacity, transportation costs, and processing requirements. Wetlap pulp retains higher moisture content, reducing drying expenses at the mill but increasing transport weight and storage demands. Dried pulp offers extended shelf life and lower shipping costs but requires additional drying energy, making the decision reliant on logistics efficiency and mill capabilities.

Wetlap pulp vs dried pulp Infographic

libmatt.com

libmatt.com