Egg tray paper offers a lightweight, cost-effective solution often made from recycled materials, providing reliable cushioning for eggs during transport. Moulded pulp, while slightly heavier, is more durable and environmentally friendly, offering superior protection and biodegradability for your packaging needs.

Table of Comparison

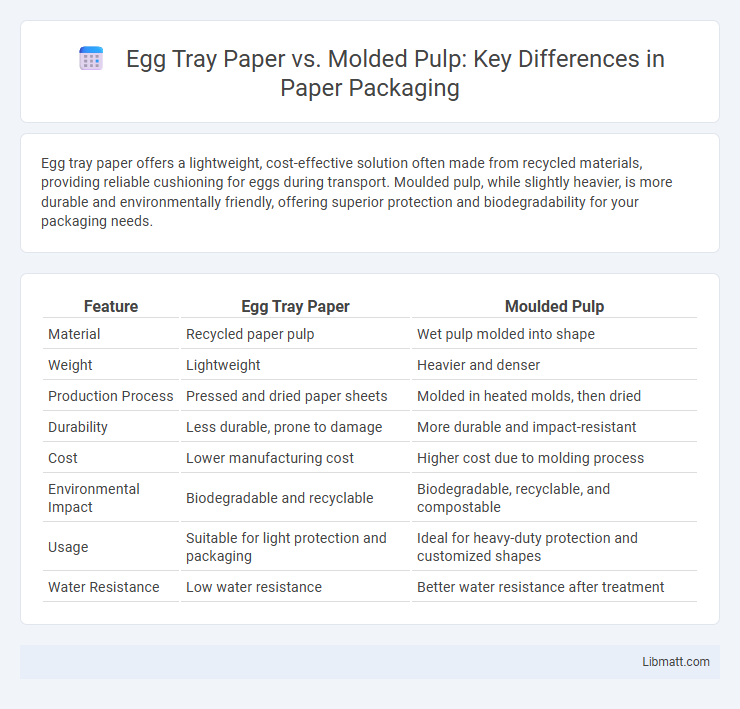

| Feature | Egg Tray Paper | Moulded Pulp |

|---|---|---|

| Material | Recycled paper pulp | Wet pulp molded into shape |

| Weight | Lightweight | Heavier and denser |

| Production Process | Pressed and dried paper sheets | Molded in heated molds, then dried |

| Durability | Less durable, prone to damage | More durable and impact-resistant |

| Cost | Lower manufacturing cost | Higher cost due to molding process |

| Environmental Impact | Biodegradable and recyclable | Biodegradable, recyclable, and compostable |

| Usage | Suitable for light protection and packaging | Ideal for heavy-duty protection and customized shapes |

| Water Resistance | Low water resistance | Better water resistance after treatment |

Overview of Egg Tray Paper and Moulded Pulp

Egg tray paper is a lightweight, recyclable material made from processed paper fibers, designed for cushioning and protecting eggs during transport. Moulded pulp is a denser, biodegradable material formed by pressing recycled paper pulp into specific shapes, offering enhanced strength and durability for egg packaging. Both materials provide eco-friendly alternatives to plastic trays, with moulded pulp being preferred for its superior structural integrity and moisture resistance.

Material Composition and Sourcing

Egg tray paper is primarily made from recycled paper materials such as old newspapers, cardboard, and office waste, which are sourced locally to promote sustainability and reduce costs. Moulded pulp trays, on the other hand, are produced by processing a mixture of recycled paper fibers combined with water, molded under heat and pressure to achieve a sturdy structure. The sourcing for both types emphasizes recycled content, but moulded pulp often involves a more refined pulp mixture for improved durability and protective cushioning.

Manufacturing Processes Compared

Egg tray paper is produced by pulping recycled paper materials, which are then molded and dried into trays using a pressurized mold, resulting in smooth, lightweight packaging. Moulded pulp manufacturing involves processing raw fibrous materials like wood fibers or recycled paper, formed in specialized molds under heat and pressure, yielding thicker and more durable trays. Your choice depends on the desired balance between resource efficiency, durability, and production complexity within these distinct manufacturing methods.

Environmental Impact and Sustainability

Egg tray paper offers superior environmental benefits due to its recyclability and biodegradability, reducing landfill waste compared to molded pulp. Molded pulp, while also biodegradable and recyclable, often requires more energy-intensive manufacturing processes that increase carbon emissions. Both materials support sustainability by using recycled fibers, but egg tray paper typically has a smaller ecological footprint through cleaner production methods and efficient resource usage.

Cost Efficiency and Affordability

Egg tray paper offers superior cost efficiency and affordability due to lower raw material expenses and simpler manufacturing processes compared to molded pulp. Its lightweight nature reduces transportation costs, enhancing overall savings for your packaging needs. Molded pulp, while sturdy, tends to incur higher production and logistics expenses, making egg tray paper the more budget-friendly choice for large-scale egg packaging.

Durability and Protective Qualities

Egg tray paper typically offers moderate durability and protective qualities, making it suitable for lightweight packaging needs. Moulded pulp, on the other hand, provides enhanced shock absorption and sturdiness, effectively cushioning eggs during transportation and minimizing breakage. Choosing moulded pulp for Your egg packaging ensures superior protection due to its resilient structure and resistance to impact.

Customization and Design Flexibility

Egg tray paper offers greater customization and design flexibility compared to molded pulp due to its ability to be easily shaped into various sizes, thicknesses, and compartment configurations through precise die-cutting and folding techniques. Molded pulp trays are generally limited by traditional molds, restricting variations in shape and intricate designs, making them less adaptable for unique packaging requirements. Advanced egg tray paper solutions enable tailored branding, printed graphics, and ergonomic designs that enhance product protection and consumer appeal.

Applications Across Industries

Egg tray paper and molded pulp both serve as sustainable packaging solutions widely used across industries such as food and beverage, electronics, and agriculture for protecting fragile items. Egg tray paper, favored for its lightweight and cost-effectiveness, primarily supports the poultry sector, while molded pulp's durability and customization options extend its application to industrial equipment packaging and consumer electronics protection. Both materials contribute to reducing environmental impact through biodegradability and recyclability, aligning with green packaging trends in manufacturing and distribution.

Recycling and End-of-Life Disposal

Egg tray paper and molded pulp both offer excellent recyclability, with molded pulp being more commonly accepted in curbside recycling programs due to its cleaner manufacturing process and lack of chemical coatings. Both materials are biodegradable and compostable, allowing for eco-friendly end-of-life disposal when industrial composting facilities are available. Proper segregation and disposal ensure these packaging options significantly reduce landfill waste compared to plastic alternatives.

Choosing the Right Packaging Solution

Choosing the right packaging solution involves comparing egg tray paper and molded pulp based on durability, environmental impact, and cost-efficiency. Egg tray paper typically offers lightweight protection with high recyclability and biodegradability, making it ideal for eco-conscious brands. Molded pulp, known for its superior cushioning and moisture resistance, suits higher-risk transportation while maintaining sustainability through compostable materials.

egg tray paper vs moulded pulp Infographic

libmatt.com

libmatt.com