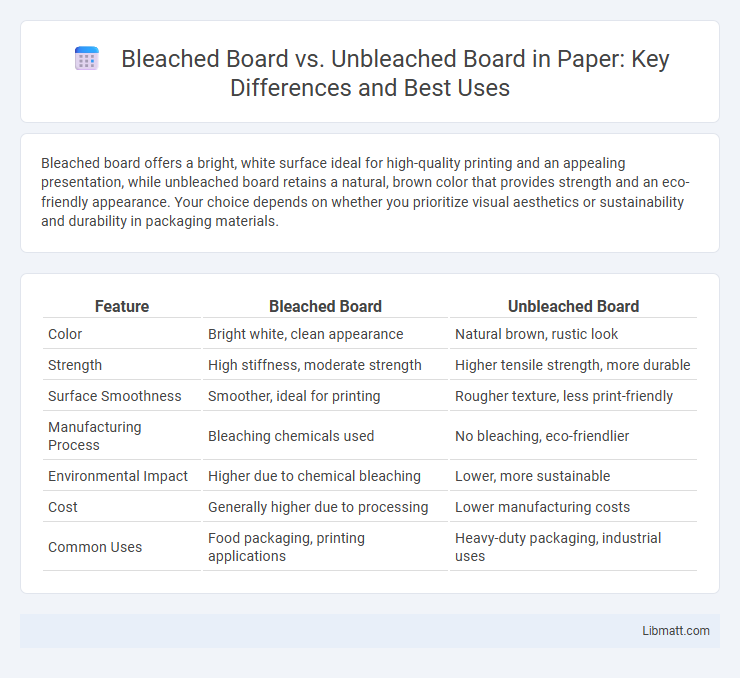

Bleached board offers a bright, white surface ideal for high-quality printing and an appealing presentation, while unbleached board retains a natural, brown color that provides strength and an eco-friendly appearance. Your choice depends on whether you prioritize visual aesthetics or sustainability and durability in packaging materials.

Table of Comparison

| Feature | Bleached Board | Unbleached Board |

|---|---|---|

| Color | Bright white, clean appearance | Natural brown, rustic look |

| Strength | High stiffness, moderate strength | Higher tensile strength, more durable |

| Surface Smoothness | Smoother, ideal for printing | Rougher texture, less print-friendly |

| Manufacturing Process | Bleaching chemicals used | No bleaching, eco-friendlier |

| Environmental Impact | Higher due to chemical bleaching | Lower, more sustainable |

| Cost | Generally higher due to processing | Lower manufacturing costs |

| Common Uses | Food packaging, printing applications | Heavy-duty packaging, industrial uses |

Introduction to Bleached and Unbleached Boards

Bleached board undergoes a chemical whitening process that produces a bright, clean surface ideal for high-quality printing and packaging. Unbleached board retains its natural brown color, offering superior stiffness and durability, frequently used for eco-friendly or heavy-duty applications. Your choice between bleached and unbleached board depends on the desired visual appeal and functional strength for your packaging needs.

What is a Bleached Board?

Bleached board is a type of paperboard treated with chemical agents to remove natural lignin and impurities, resulting in a bright white surface ideal for high-quality printing and packaging. Its smooth texture and enhanced brightness make it preferred for premium product packaging, ensuring vibrant color reproduction and a clean appearance. Your choice of bleached board can significantly impact the visual appeal and perceived value of branded goods.

What is an Unbleached Board?

Unbleached board is a type of paperboard made from kraft pulp that retains its natural brown color, providing increased strength and a more rustic appearance compared to bleached board. This material is often preferred for eco-friendly packaging due to its minimal chemical processing and higher durability. Your choice of unbleached board supports sustainability while maintaining a sturdy, natural finish ideal for product protection and aesthetics.

Manufacturing Process Comparison

Bleached board undergoes a chemical treatment using chlorine or chlorine dioxide, which removes lignin to produce a bright, white surface ideal for high-quality printing and packaging. Unbleached board retains its natural brown color as it bypasses the bleaching step, preserving lignin and resulting in a stronger, more rigid structure suitable for heavy-duty applications. The manufacturing process for bleached board involves higher energy consumption and chemical usage compared to unbleached board, which is more eco-friendly due to its simpler, less resource-intensive production.

Key Physical and Visual Differences

Bleached board features a bright white surface achieved through chemical treatment, offering a smooth, clean appearance ideal for high-quality printing and packaging. Unbleached board retains its natural brown color, resulting in a coarser texture with a rustic, organic look and increased stiffness and durability. These physical and visual differences affect usability, with bleached board preferred for retail packaging and unbleached favored for shipping containers and eco-friendly products.

Environmental Impact Analysis

Bleached board production involves chemical treatments that release chlorine compounds, increasing water pollution and energy consumption compared to unbleached board. Unbleached board, made without bleaching agents, has a lower environmental footprint due to reduced chemical use and higher recyclability, making it a more sustainable choice for packaging. Considering the environmental impact analysis, your selection of unbleached board supports eco-friendly practices and minimizes harmful emissions.

Applications and Industry Usage

Bleached board is predominantly used in food packaging, pharmaceutical containers, and cosmetic boxes due to its bright white surface that enhances print quality and consumer appeal. Unbleached board, characterized by its natural brown color and higher durability, is commonly applied in industrial packaging, bulk shipping containers, and eco-friendly product packaging. Industries such as food service, retail, and manufacturing select bleached or unbleached boards based on aesthetic requirements and strength needs.

Cost Differences: Bleached vs Unbleached

Bleached board typically costs more than unbleached board due to the additional chemical processing required to achieve its white, bright appearance. Unbleached board offers a more economical option for packaging and printing projects that prioritize natural, rustic aesthetics without sacrificing durability. Your choice between bleached and unbleached board should consider budget constraints alongside the desired visual impact and environmental factors.

Sustainability and Recycling Considerations

Bleached board uses chemical treatments that can impact its recyclability due to residual bleaching agents, while unbleached board typically offers better sustainability by avoiding harmful chemicals and promoting easier recycling processes. Your choice between the two affects environmental footprint, with unbleached board generally preferred for eco-friendly packaging solutions and reduced waste contamination. Recycling facilities favor unbleached board since it requires less intensive processing and supports circular economy goals.

Choosing the Right Board for Your Needs

Bleached board offers a bright white surface ideal for high-quality printing and branding, making it perfect for premium packaging and presentation materials. Unbleached board, featuring a natural brown tone, provides excellent durability and eco-friendly appeal, suitable for sustainable packaging and products emphasizing environmental responsibility. Selecting between bleached and unbleached boards depends on the desired aesthetic, printing requirements, and sustainability goals of your project.

bleached board vs unbleached board Infographic

libmatt.com

libmatt.com