Cast-coated paper offers a glossy, mirror-like finish achieved by curing the paper against a heated, polished cylinder, resulting in exceptional smoothness and high-quality image reproduction. Machine-finished coated paper features a smoother surface than uncoated options but provides a less reflective finish, making it suitable for standard printing needs while maintaining cost efficiency.

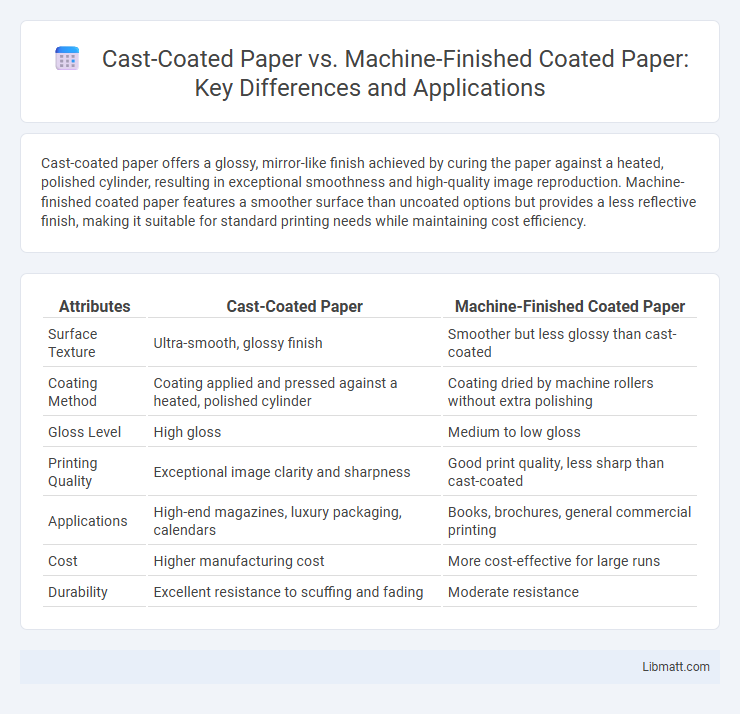

Table of Comparison

| Attributes | Cast-Coated Paper | Machine-Finished Coated Paper |

|---|---|---|

| Surface Texture | Ultra-smooth, glossy finish | Smoother but less glossy than cast-coated |

| Coating Method | Coating applied and pressed against a heated, polished cylinder | Coating dried by machine rollers without extra polishing |

| Gloss Level | High gloss | Medium to low gloss |

| Printing Quality | Exceptional image clarity and sharpness | Good print quality, less sharp than cast-coated |

| Applications | High-end magazines, luxury packaging, calendars | Books, brochures, general commercial printing |

| Cost | Higher manufacturing cost | More cost-effective for large runs |

| Durability | Excellent resistance to scuffing and fading | Moderate resistance |

Introduction to Coated Papers

Coated papers enhance print quality by applying a surface layer that improves brightness, smoothness, and ink holdout. Cast-coated paper undergoes a process where the coated paper is pressed against a highly polished, heated cylinder, resulting in a glossy, mirror-like finish with excellent clarity and sharpness. Machine-finished coated paper achieves a smoother surface through calendering, offering a balance between cost-efficiency and print quality for magazines, brochures, and catalogs.

What is Cast-Coated Paper?

Cast-coated paper features a glossy, polished surface achieved by pressing the paper against a polished metal drum during manufacturing, resulting in high-gloss brilliance and smoothness ideal for premium printing. Machine-finished coated paper, in contrast, is calendered through rollers to create a smooth but less reflective finish with moderate gloss. Your choice between these papers depends on the desired print quality and visual impact, with cast-coated paper offering superior sharpness and color vibrancy.

What is Machine-Finished Coated Paper?

Machine-finished coated paper (MFC) is a type of coated paper produced by applying a coating while the paper is still on the machine, resulting in a smoother surface finish. This paper typically offers enhanced brightness, smoothness, and printability, suitable for high-quality printing applications such as catalogs and magazines. Unlike cast-coated paper, MFC lacks mirror-like gloss but provides a balanced finish with good opacity and bulk.

Manufacturing Processes Compared

Cast-coated paper undergoes a process where a wet coated sheet is pressed against a highly polished steel drum to achieve a smooth, glossy finish, enhancing brightness and print quality. Machine-finished coated paper is produced by applying coatings during the papermaking process and then mechanically calendaring the sheet to improve smoothness and gloss, resulting in a less reflective surface compared to cast-coated paper. The cast coating process yields higher gloss and smoothness due to the rapid drying and surface replication, while machine finishing offers cost-effective production with moderate surface qualities.

Surface Properties and Finish

Cast-coated paper features a glossy, mirror-like surface achieved by drying paper against a polished metal cylinder, resulting in a smooth, high-gloss finish ideal for premium printing quality and sharp image reproduction. Machine-finished coated paper undergoes calendering with rollers, producing a semi-gloss to matte surface with less reflectivity and texture variations suited for general printing applications. The cast-coated finish provides superior ink holdout and visual depth compared to the relatively lower gloss and tactile texture of machine-finished coated paper.

Print Quality and Color Reproduction

Cast-coated paper delivers superior print quality and vibrant color reproduction due to its ultra-smooth, high-gloss surface created by curing the coating on a polished drum, which enhances sharpness and detail. Machine-finished coated paper, produced by mechanically smoothing the coating before drying, offers good print quality but generally lacks the exceptional gloss and color intensity found in cast-coated paper. The difference in coating application impacts ink absorption and light reflection, making cast-coated paper a preferred choice for premium printing projects requiring precise color accuracy and brilliance.

Durability and Handling

Cast-coated paper offers superior durability with a high-gloss finish that resists scratches and scuffs, making it ideal for premium packaging and labels requiring long-lasting protection. Machine-finished coated paper, while smoother and more cost-effective, is less resistant to wear and can be prone to surface damage during handling and transportation. Your choice should consider the balance between durability needs and budget constraints for optimal handling performance.

Typical Applications and Uses

Cast-coated paper is widely used in high-quality printing applications such as luxury packaging, labels, and photo books because of its glossy finish and excellent ink holdout, enhancing visual appeal. Machine-finished coated paper is commonly utilized for magazines, catalogs, and brochures due to its smooth surface and cost-effective production, offering good image clarity and durability. Understanding the differences in typical applications helps you choose the right paper type to meet your printing quality and budget requirements.

Cost and Availability

Cast-coated paper typically incurs higher costs due to its glossy, high-quality finish achieved through a specialized casting process, making it less readily available than machine-finished coated paper. Machine-finished coated paper offers a more affordable option with broader availability, as it is produced using standard coating and drying techniques suitable for mass production. Your choice depends on balancing budget constraints with the desired quality and accessibility for your printing needs.

Choosing the Right Paper for Your Project

Cast-coated paper offers a high-gloss, mirror-like finish ideal for vibrant, high-end printing projects requiring sharp images and bright colors. Machine-finished coated paper provides a smoother but less reflective surface, suitable for general-purpose printing with good ink holdout and faster production times. Your choice depends on the desired visual impact and budget, with cast-coated paper excelling in luxury packaging and magazine covers, while machine-finished is preferred for brochures and catalogs.

Cast-coated paper vs machine-finished coated paper Infographic

libmatt.com

libmatt.com