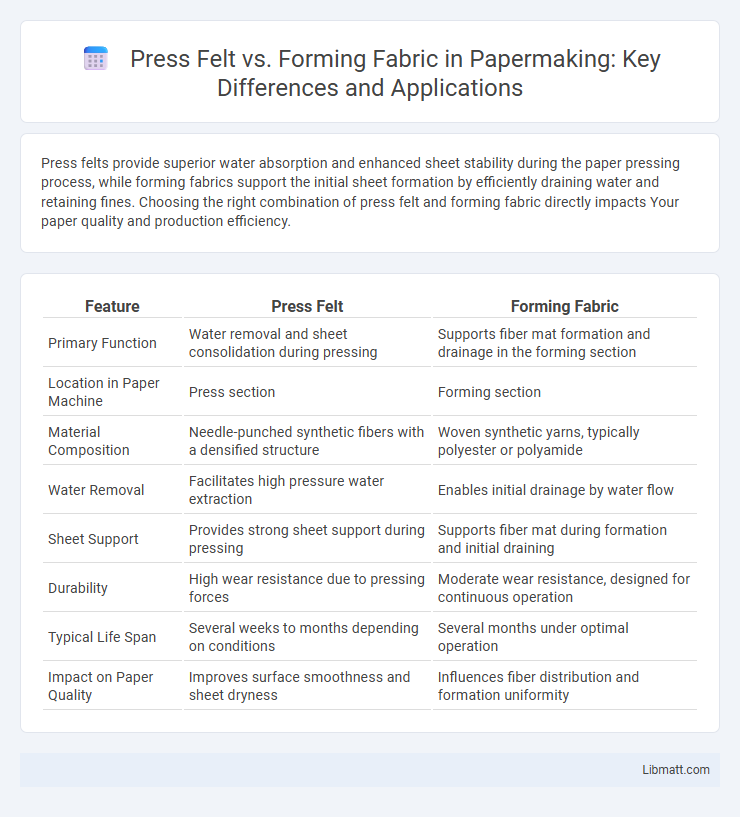

Press felts provide superior water absorption and enhanced sheet stability during the paper pressing process, while forming fabrics support the initial sheet formation by efficiently draining water and retaining fines. Choosing the right combination of press felt and forming fabric directly impacts Your paper quality and production efficiency.

Table of Comparison

| Feature | Press Felt | Forming Fabric |

|---|---|---|

| Primary Function | Water removal and sheet consolidation during pressing | Supports fiber mat formation and drainage in the forming section |

| Location in Paper Machine | Press section | Forming section |

| Material Composition | Needle-punched synthetic fibers with a densified structure | Woven synthetic yarns, typically polyester or polyamide |

| Water Removal | Facilitates high pressure water extraction | Enables initial drainage by water flow |

| Sheet Support | Provides strong sheet support during pressing | Supports fiber mat during formation and initial draining |

| Durability | High wear resistance due to pressing forces | Moderate wear resistance, designed for continuous operation |

| Typical Life Span | Several weeks to months depending on conditions | Several months under optimal operation |

| Impact on Paper Quality | Improves surface smoothness and sheet dryness | Influences fiber distribution and formation uniformity |

Introduction to Press Felt and Forming Fabric

Press felt and forming fabric are essential components in the papermaking process, each serving a distinct function in the paper machine. Forming fabric acts as a conveyor belt that supports the wet fiber web during initial dewatering and formation, ensuring even fiber distribution and sheet formation. Press felt, on the other hand, is used in the pressing section to absorb water squeezed from the paper web, improving sheet dryness and surface quality before drying.

Key Functions in the Papermaking Process

Press felt and forming fabric serve distinct yet crucial roles in the papermaking process, optimizing water removal and sheet formation. The forming fabric supports the paper web during initial water drainage, ensuring fiber alignment for sheet strength and uniformity. Press felt enhances water extraction through mechanical pressing, improving sheet dryness and surface quality, directly impacting your paper production efficiency.

Composition and Material Differences

Press felt is typically made from densely woven synthetic fibers like polyester or nylon combined with natural fibers, designed to withstand high pressure and moisture removal in paper machines. Forming fabric primarily consists of a three-layer synthetic material structure, usually polyester or polypropylene, engineered for excellent water drainage and sheet formation. Your choice depends on the papermaking stage, where press felts focus on water extraction and forming fabrics emphasize fiber support and drainage.

Structural Design & Weaving Techniques

Press felt features a multi-layered structure with varied fiber compositions that enhance water absorption and durability, woven using complex patterns like cross-laid or engineered weaves to optimize moisture transfer and dewatering efficiency. Forming fabric typically employs a seamless circular weaving technique with uniform yarns designed for open mesh structure, promoting excellent drainage and sheet formation. The structural design of press felt prioritizes mechanical strength and rewet resistance, while forming fabric emphasizes fiber uniformity and minimal voids to ensure consistent paper formation and quality.

Performance in Water Removal

Press felt excels in water removal during the pressing stage of papermaking by efficiently absorbing and transporting water away from the sheet, contributing to higher dryness and improved sheet structure. Forming fabric primarily supports initial water drainage from the paper pulp in the forming section, using its permeability and mesh design to enhance drainage without compressing the fibers. Optimal water removal performance depends on selecting press felts with high absorbency and durability alongside forming fabrics designed for rapid, uniform dewatering in the wire section.

Impact on Paper Quality

Press felt plays a critical role in maintaining paper moisture levels and uniformity during the pressing stage, directly influencing paper smoothness and density. Forming fabric primarily affects fiber orientation and sheet formation uniformity, which determines structural strength and surface texture. The combined optimization of press felt and forming fabric enhances overall paper quality by balancing moisture removal with fiber arrangement.

Durability and Lifespan Comparison

Press felt typically demonstrates higher durability due to its dense fiber construction and resistance to high-pressure environments, contributing to an extended lifespan in paper machine pressing sections. Forming fabric, while engineered for optimum sheet formation and drainage, generally experiences faster wear and shorter operational life because of constant exposure to water, paper fibers, and mechanical stresses. Choosing press felt over forming fabric can result in reduced replacement frequency and lower maintenance costs in heavy-duty paper production processes.

Maintenance and Operational Considerations

Press felt requires regular cleaning and conditioning to maintain its moisture absorption and durability, which directly influences sheet quality and production efficiency. Forming fabric demands careful monitoring to prevent fiber wear and ensure consistent water drainage, crucial for forming uniform paper sheets. Optimizing maintenance schedules for both components enhances your operational uptime and product quality in the papermaking process.

Cost Implications and Economic Factors

Press felt typically incurs higher costs than forming fabric due to its durability, specialized materials, and frequent replacement requirements in high-pressure sections of paper machines. Forming fabric offers cost efficiency by reducing sheet defects and improving machine runnability, directly impacting your operational expenses. Evaluating the lifecycle costs, including maintenance, longevity, and efficiency gains, helps optimize your investment between press felts and forming fabrics.

Selecting the Right Fabric for Optimal Results

Selecting the right fabric is crucial for achieving optimal results in paper production, with press felt and forming fabric serving distinct roles. Press felt efficiently absorbs water and provides support during the pressing stage, while forming fabric ensures uniform fiber distribution and sheet formation in the initial phase. Understanding your machine's requirements and the specific properties of each fabric will enhance sheet quality, improve machine speed, and reduce operational costs.

Press felt vs forming fabric Infographic

libmatt.com

libmatt.com