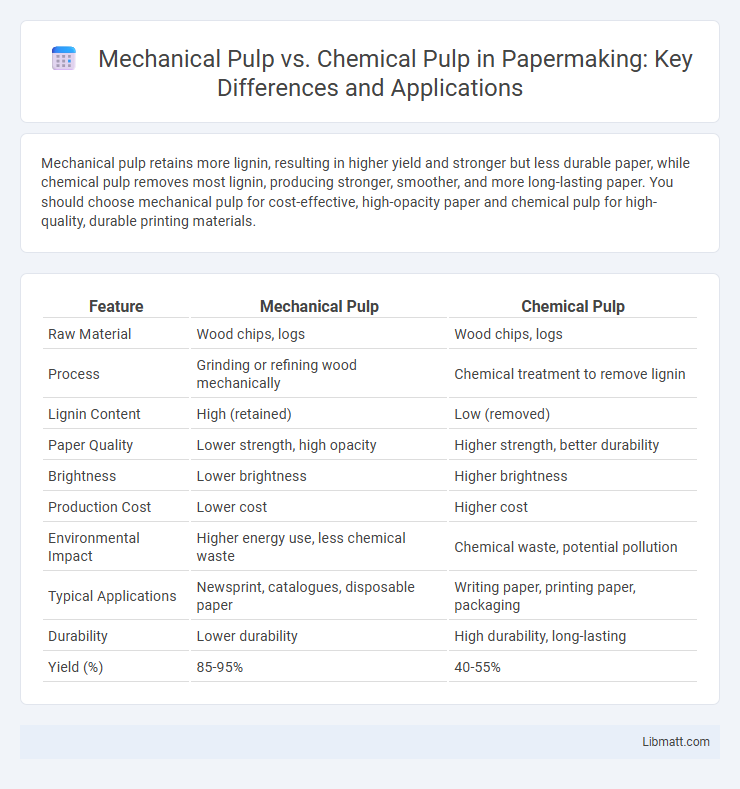

Mechanical pulp retains more lignin, resulting in higher yield and stronger but less durable paper, while chemical pulp removes most lignin, producing stronger, smoother, and more long-lasting paper. You should choose mechanical pulp for cost-effective, high-opacity paper and chemical pulp for high-quality, durable printing materials.

Table of Comparison

| Feature | Mechanical Pulp | Chemical Pulp |

|---|---|---|

| Raw Material | Wood chips, logs | Wood chips, logs |

| Process | Grinding or refining wood mechanically | Chemical treatment to remove lignin |

| Lignin Content | High (retained) | Low (removed) |

| Paper Quality | Lower strength, high opacity | Higher strength, better durability |

| Brightness | Lower brightness | Higher brightness |

| Production Cost | Lower cost | Higher cost |

| Environmental Impact | Higher energy use, less chemical waste | Chemical waste, potential pollution |

| Typical Applications | Newsprint, catalogues, disposable paper | Writing paper, printing paper, packaging |

| Durability | Lower durability | High durability, long-lasting |

| Yield (%) | 85-95% | 40-55% |

Introduction to Mechanical and Chemical Pulp

Mechanical pulp is produced by physically grinding wood logs or chips to separate fibers, resulting in higher yield and retained lignin, which affects paper brightness and durability. Chemical pulp uses chemical agents like sodium hydroxide and sodium sulfide in processes such as kraft or sulfite pulping to dissolve lignin, producing stronger and more durable fibers with higher brightness but lower yield. The choice between mechanical and chemical pulp depends on desired paper properties, production costs, and environmental considerations.

Overview of the Pulping Process

Mechanical pulp is produced by physically grinding wood logs or chips, retaining most of the lignin and resulting in higher yield but lower paper strength and brightness. Chemical pulp involves cooking wood chips with chemicals like sodium hydroxide and sodium sulfide to remove lignin, producing stronger, brighter paper but with lower yield. Understanding these differences helps you choose the right pulping process based on desired paper quality and production efficiency.

Raw Materials for Pulp Production

Mechanical pulp is primarily produced from softwood logs using high-pressure grinding, retaining most of the lignin and resulting in higher yields but lower brightness. Chemical pulp requires wood chips from both hardwood and softwood, where chemicals like sodium hydroxide and sodium sulfide break down lignin, producing stronger, brighter fibers with lower yield. Your choice between mechanical and chemical pulp depends on the desired paper quality and raw material availability.

Mechanical Pulping: Methods and Characteristics

Mechanical pulping involves refining wood chips into pulp using grinding or refining techniques, such as stone groundwood (SGW), refiner mechanical pulp (RMP), and thermomechanical pulp (TMP). This method preserves most of the lignin and hemicellulose, resulting in higher yield but weaker paper strength and lower brightness compared to chemical pulping. Mechanical pulps are mainly used for newsprint and low-cost paper products due to their higher opacity and bulk.

Chemical Pulping: Methods and Characteristics

Chemical pulping involves processes such as the Kraft and sulfite methods, where wood chips are cooked with chemicals like sodium hydroxide and sodium sulfide to break down lignin and separate fibers. This method produces stronger, higher-quality pulp with longer fibers suitable for printing and writing papers, due to reduced fiber damage and lower lignin content. Chemical pulps typically exhibit higher brightness, better opacity, and improved durability compared to mechanical pulps, which contain more lignin and shorter fibers.

Fiber Quality: Mechanical vs Chemical Pulp

Mechanical pulp retains most of the wood's original components, resulting in shorter, less flexible fibers that yield higher opacity but lower strength. Chemical pulp undergoes processing that removes lignin and impurities, producing longer, stronger fibers ideal for durable paper products. Understanding these differences helps you select the appropriate pulp type for your desired paper strength and quality.

Energy Consumption and Efficiency

Mechanical pulp production consumes significantly more energy, often up to 10 times higher than chemical pulping processes, due to intensive grinding and refining operations. Chemical pulp processes, such as kraft or sulfite, are more energy-efficient as they rely on chemical reactions to break down lignin, reducing the need for mechanical force. This energy efficiency makes chemical pulping preferable for large-scale, sustainable paper manufacturing despite its longer processing time.

Environmental Impact Comparison

Mechanical pulp production consumes less energy but results in higher water pollution due to the release of organic matter. Chemical pulp processes use more energy and chemicals but produce cleaner wastewater with lower biological oxygen demand (BOD). Your choice between mechanical and chemical pulp affects overall environmental footprint, balancing energy use against water quality impact.

Applications and End-Use Products

Mechanical pulp is commonly used in the production of newsprint, catalogs, and paperboard due to its high yield and good bulk, making it ideal for short-life printing materials. Chemical pulp, with its superior strength and brightness, is preferred for high-quality printing papers, packaging, and tissue products where durability and appearance are critical. Your choice between mechanical and chemical pulp affects the durability, appearance, and recyclability of the final paper product, tailoring it to specific industrial applications.

Future Trends in Pulping Technologies

Emerging future trends in pulping technologies emphasize sustainability and efficiency, with mechanical pulp advancing through energy-saving refinements and chemical pulp evolving via eco-friendly, enzyme-assisted processes. Innovations such as biopulping and integrated biorefinery approaches aim to reduce environmental impact while maintaining fiber quality and yield. You can expect ongoing research to enhance chemical recovery methods and develop hybrid pulping systems that combine mechanical and chemical advantages for improved resource utilization.

Mechanical pulp vs chemical pulp Infographic

libmatt.com

libmatt.com