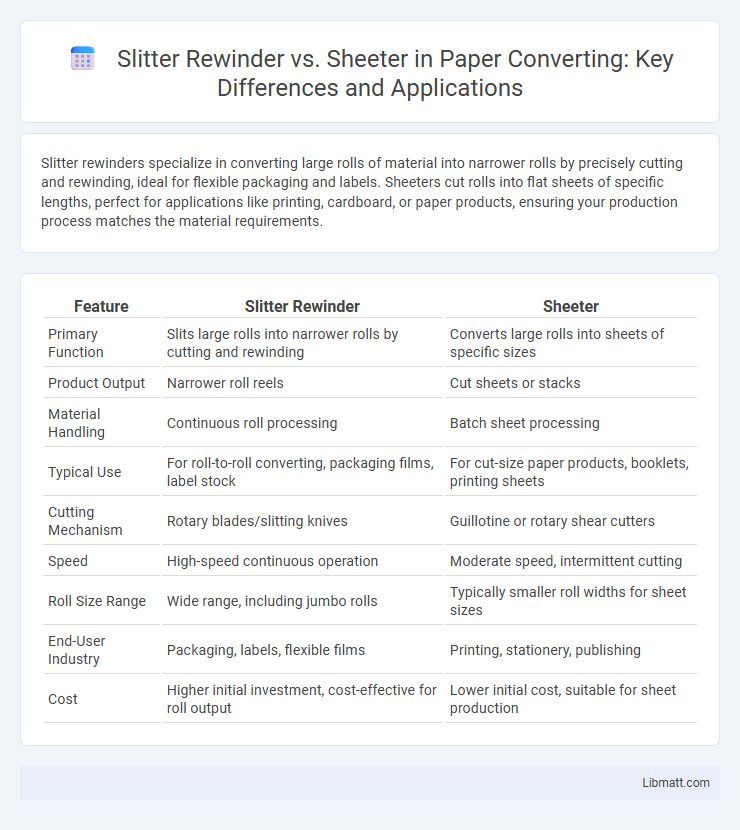

Slitter rewinders specialize in converting large rolls of material into narrower rolls by precisely cutting and rewinding, ideal for flexible packaging and labels. Sheeters cut rolls into flat sheets of specific lengths, perfect for applications like printing, cardboard, or paper products, ensuring your production process matches the material requirements.

Table of Comparison

| Feature | Slitter Rewinder | Sheeter |

|---|---|---|

| Primary Function | Slits large rolls into narrower rolls by cutting and rewinding | Converts large rolls into sheets of specific sizes |

| Product Output | Narrower roll reels | Cut sheets or stacks |

| Material Handling | Continuous roll processing | Batch sheet processing |

| Typical Use | For roll-to-roll converting, packaging films, label stock | For cut-size paper products, booklets, printing sheets |

| Cutting Mechanism | Rotary blades/slitting knives | Guillotine or rotary shear cutters |

| Speed | High-speed continuous operation | Moderate speed, intermittent cutting |

| Roll Size Range | Wide range, including jumbo rolls | Typically smaller roll widths for sheet sizes |

| End-User Industry | Packaging, labels, flexible films | Printing, stationery, publishing |

| Cost | Higher initial investment, cost-effective for roll output | Lower initial cost, suitable for sheet production |

Introduction to Slitter Rewinder and Sheeter Machines

Slitter rewinders and sheeter machines serve distinct functions in converting large rolls of material into smaller, usable formats. Slitter rewinders precisely cut wide rolls into narrower strips and rewind them onto cores, ideal for films, foils, and paper products. Sheeter machines, on the other hand, slice continuous rolls into flat sheets, commonly used in packaging, printing, and industrial applications requiring uniform sheet sizes.

How Slitter Rewinders Work

Slitter rewinders operate by unwinding large rolls of material and precisely cutting them into narrower widths using rotary blades before rewinding them into smaller rolls. The tension control system maintains consistent material tension throughout the process to ensure clean, accurate cuts and smooth edges. These machines excel in converting plastic films, paper, and foil into customized roll sizes for various industrial applications.

How Sheeters Operate

Sheeters operate by feeding large rolls of material into a cutting system that slices the material into sheets of precise length and width, using rotary or guillotine knives for high-speed accuracy. The sheeted output is then stacked or delivered for further processing, ensuring consistent dimensions tailored to specific applications. This process contrasts with slitter rewinders, which primarily cut rolls into narrower rolls rather than individual sheets.

Key Differences Between Slitter Rewinders and Sheeters

Slitter rewinders are designed to convert large rolls of material into narrower rolls by precisely cutting and rewinding the web, ideal for films, foils, and paper. Sheeters, conversely, transform continuous rolls into flat sheets of specific lengths, commonly used in paper, cardboard, and plastic sheet production. Your choice depends on whether you need rolled or sheeted output, with slitter rewinders focusing on roll-to-roll processing and sheeters emphasizing cut-to-sheet functionality.

Material Compatibility: Slitter Rewinder vs Sheeter

Slitter rewinders excel in processing flexible materials such as plastic films, foils, and laminates, offering precise width slitting and rewinding without compromising material integrity. Sheeters are primarily designed for rigid or semi-rigid materials like paperboard, cardboard, and thicker paper grades, converting large rolls into flat sheets with clean, accurate cuts. Material compatibility dictates the choice between these machines, with slitter rewinders ideal for thin, flexible substrates and sheeters best suited for thicker, sheet-based products.

Productivity and Efficiency Comparison

Slitter rewinders excel in productivity by efficiently converting large rolls of material into narrower rolls with minimal waste, making them ideal for high-volume production. Sheeters enhance efficiency through precise cutting of materials into sheets, optimizing workflow for applications requiring uniform sheet sizes. The choice between the two depends on whether the priority is continuous roll processing or batch sheet cutting, affecting overall operational productivity.

Cost Analysis: Slitter Rewinder vs Sheeter

Slitter rewinders typically involve higher initial investment costs compared to sheeters due to their complex components and advanced automation. Operating expenses for slitter rewinders can be more cost-efficient when processing long rolls, as they minimize material waste and increase production speed. Your choice between the two should consider total cost of ownership, including maintenance, labor, and energy consumption specific to your production volume and application needs.

Quality Control Capabilities

Slitter rewinders offer precise control over web tension and cutting accuracy, ensuring high-quality rolls with minimal defects, which is crucial for applications demanding consistent dimensions and smooth edges. Sheeters excel in producing uniform sheets with clean, straight cuts, leveraging advanced sensors and adjustable knives to maintain tight tolerances and reduce material waste. Both machines integrate real-time inspection systems and automated adjustments to enhance quality control, but slitter rewinders provide superior capabilities for continuous roll quality monitoring.

Application Industries for Each Machine

Slitter rewinders are widely used in packaging, printing, and converting industries where precise cutting of large rolls into narrow widths is essential for materials like films, foils, and paper. Sheeters find their primary application in paper manufacturing, printing, and corrugated board production, efficiently transforming large rolls into sheets of specific lengths for further processing or printing. Your choice between the two machines depends on whether your industry requires continuous roll handling or discrete sheet production for its operations.

Choosing the Right Solution for Your Production Needs

Slitter rewinders excel in converting large rolls into narrower rolls, providing precise slitting and rewinding for various materials like films, foils, and paper, making them ideal for flexible packaging and label production. Sheeters are designed to convert rolls into flat sheets of specific lengths, perfect for applications requiring uniform sheet sizes such as paper printing, cardboard, and plastic sheet industries. Assessing factors such as material type, end-use requirements, speed, and production volume is crucial for selecting the right equipment that maximizes efficiency and meets specific manufacturing goals.

Slitter rewinder vs sheeter Infographic

libmatt.com

libmatt.com