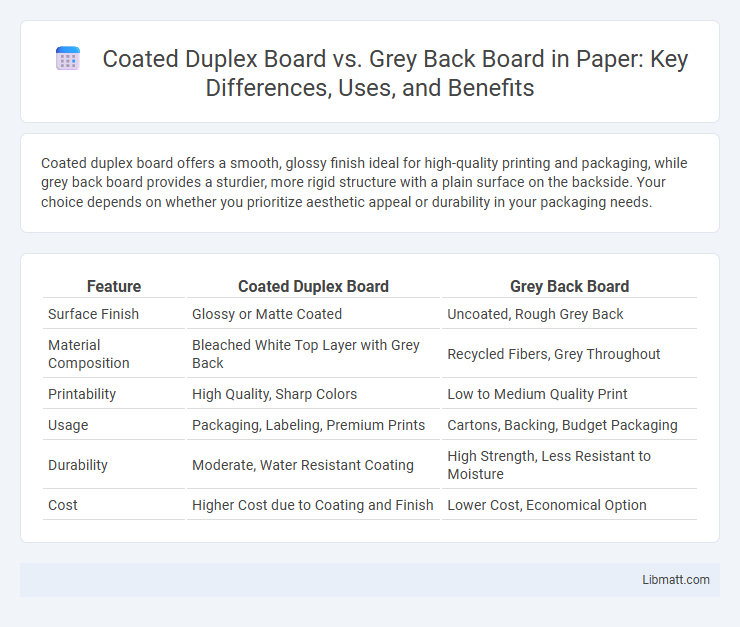

Coated duplex board offers a smooth, glossy finish ideal for high-quality printing and packaging, while grey back board provides a sturdier, more rigid structure with a plain surface on the backside. Your choice depends on whether you prioritize aesthetic appeal or durability in your packaging needs.

Table of Comparison

| Feature | Coated Duplex Board | Grey Back Board |

|---|---|---|

| Surface Finish | Glossy or Matte Coated | Uncoated, Rough Grey Back |

| Material Composition | Bleached White Top Layer with Grey Back | Recycled Fibers, Grey Throughout |

| Printability | High Quality, Sharp Colors | Low to Medium Quality Print |

| Usage | Packaging, Labeling, Premium Prints | Cartons, Backing, Budget Packaging |

| Durability | Moderate, Water Resistant Coating | High Strength, Less Resistant to Moisture |

| Cost | Higher Cost due to Coating and Finish | Lower Cost, Economical Option |

Introduction to Coated Duplex Board and Grey Back Board

Coated duplex board features a smooth, coated outer surface with a grey, uncoated backside, providing excellent printability and durability for packaging and printing applications. Grey back board consists of two layers: a coated white top surface for high-quality graphics and a grey recycled fiber back, valued for its rigidity and cost-effective nature. Both boards are widely used in product packaging, retail displays, and printing industries where a balance of appearance and strength is essential.

Material Composition and Structure

Coated duplex board features a white, clay-coated top layer on bleached paperboard, providing a smooth surface ideal for high-quality printing, while the backside remains uncoated and grey. Grey back board, on the other hand, consists of recycled fibers with a grey uncoated surface on both sides, offering a more economical and eco-friendly structure. Your choice depends on whether you require superior printability and appearance or cost-effective and sustainable packaging material.

Manufacturing Process Differences

Coated duplex board involves applying a clay coating to one side of the grey back board, enhancing surface smoothness and print quality, while grey back board is produced using recycled fibers without any surface coating. The manufacturing process of coated duplex board includes an additional coating stage that improves whiteness and brightness, making it ideal for high-quality packaging and graphic applications. Your choice depends on whether you need superior printability or a more cost-effective, eco-friendly material.

Surface Finishing and Printability

Coated duplex board features a smooth, glossy surface achieved through a clay coating, enhancing printability and allowing vibrant, sharp image reproduction ideal for high-quality packaging and promotional materials. Grey back board has a rougher surface and lacks coating on the printable side, resulting in lower print clarity and less color vibrancy, though it remains suitable for applications where cost efficiency and strength are prioritized over visual appeal. Your choice between these boards should consider the desired finish quality and printing precision for your specific project needs.

Strength and Durability Comparison

Coated duplex board offers superior strength and durability due to its dual-layer construction and protective coating, making it resistant to moisture and external damage. Grey back board, typically single-ply and uncoated, exhibits lower durability and is more prone to wear, tear, and water absorption. The robust nature of coated duplex board makes it ideal for packaging requiring enhanced structural integrity and resistance to environmental factors.

Applications in Packaging Industry

Coated duplex board offers a smooth, printable surface ideal for high-quality packaging such as luxury cosmetics and food products, enhancing brand appeal through vibrant graphics. Grey back board, featuring a sturdy and cost-effective construction with a grey reverse side, is commonly used for secondary packaging and cartons focused on durability over aesthetics. Your choice between these boards depends on whether visual presentation or structural strength is the priority in your packaging design.

Environmental Impact and Recyclability

Coated duplex board features a clay-coated top layer on recycled pulp, offering improved print quality while maintaining good recyclability and lower environmental impact due to its recycled content. Grey back board is made from recycled fibers with a grey back layer, often used for durability but sometimes less favored in recycling processes due to the presence of additives or mixed materials. Your choice between these boards affects sustainability, as coated duplex board typically supports more efficient recycling and has a smaller carbon footprint compared to grey back board.

Cost Effectiveness and Market Price

Coated duplex board typically offers higher durability and a premium finish at a slightly elevated market price compared to grey back board, which is more cost-effective for budget-sensitive packaging needs. Grey back board serves as an economical option due to its lower production costs and suitability for short-term or disposable uses. Your choice between these boards should balance quality requirements with cost constraints to maximize value.

Pros and Cons of Coated Duplex Board

Coated duplex board offers superior print quality and a smooth, glossy surface ideal for high-end packaging and branding, enhancing visual appeal and color vibrancy. Its moisture resistance and durability make it suitable for food packaging, but it is generally more expensive and less eco-friendly compared to grey back board. While coated duplex board excels in aesthetics and protection, it may lack the structural strength and recyclability benefits associated with grey back board.

Pros and Cons of Grey Back Board

Grey back board offers excellent rigidity and cost-effectiveness, making it ideal for packaging and printing applications where durability is essential. Its recycled content promotes sustainability, but the rough grey backside can limit aesthetic appeal compared to the smooth, coated duplex board surface. You should consider grey back board if budget-friendly strength is your priority, though it may lack the premium finish required for high-end presentations.

Coated duplex board vs grey back board Infographic

libmatt.com

libmatt.com