Kraft paper, known for its durability and coarse texture, is ideal for packaging and wrapping due to its high tear resistance and natural brown color. Bond paper, characterized by its smooth finish and whiteness, is commonly used for printing documents and stationery, offering excellent ink absorption and professional appearance.

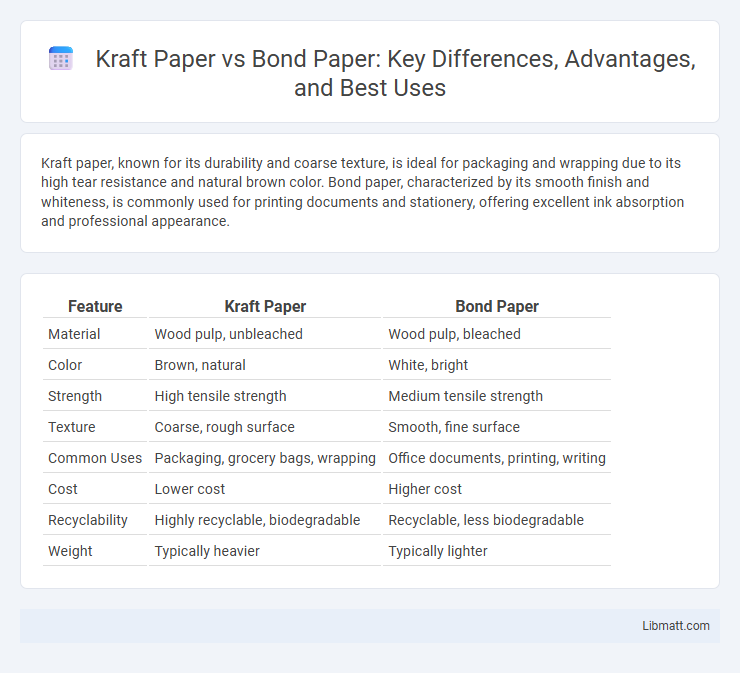

Table of Comparison

| Feature | Kraft Paper | Bond Paper |

|---|---|---|

| Material | Wood pulp, unbleached | Wood pulp, bleached |

| Color | Brown, natural | White, bright |

| Strength | High tensile strength | Medium tensile strength |

| Texture | Coarse, rough surface | Smooth, fine surface |

| Common Uses | Packaging, grocery bags, wrapping | Office documents, printing, writing |

| Cost | Lower cost | Higher cost |

| Recyclability | Highly recyclable, biodegradable | Recyclable, less biodegradable |

| Weight | Typically heavier | Typically lighter |

Introduction to Kraft Paper and Bond Paper

Kraft paper is a durable, coarse paper made from chemical pulp produced through the kraft process, known for its high strength and brown color, commonly used in packaging and industrial applications. Bond paper features a smoother texture, lighter weight, and is primarily made from chemical pulp with cotton or linen fibers, making it ideal for official documents, letterheads, and office printing. Each type serves distinct purposes based on its fiber composition and finish, with Kraft paper emphasizing durability and bond paper prioritizing print quality and appearance.

Composition and Manufacturing Process

Kraft paper is produced from wood pulp through the kraft process, which uses chemical treatment to remove lignin and produces strong, coarse fibers ideal for packaging and industrial use. Bond paper is made from high-quality cotton or wood pulp, refined to create a smooth, durable surface suitable for writing and printing, often through mechanical and chemical pulping methods. The kraft process emphasizes strength and durability, while bond paper manufacturing prioritizes a fine texture and brightness for office and stationery applications.

Physical Properties Comparison

Kraft paper is known for its high tensile strength, durability, and coarse texture, making it ideal for heavy-duty packaging and wrapping. Bond paper features a smoother surface, lower gram weight, and higher brightness, commonly used for printing, writing, and office documents. The physical properties of kraft paper include thicker fibers and the presence of lignin, while bond paper is refined and bleached, resulting in a lighter, more flexible sheet.

Common Uses of Kraft Paper

Kraft paper is commonly used for packaging, wrapping, and industrial applications due to its strength and durability. It is ideal for making paper bags, envelopes, and protective covers in shipping and construction industries. Its natural brown color and tear resistance also make it popular for eco-friendly and recyclable packaging solutions.

Typical Applications of Bond Paper

Bond paper is commonly used for official documents, letterheads, envelopes, and stationery due to its smooth texture and durability. Its high-quality finish makes it ideal for printing resumes, business forms, and invoices requiring a professional appearance. Bond paper is preferred in offices and legal environments for important communications and record-keeping.

Strength and Durability

Kraft paper is renowned for its exceptional strength and durability, making it ideal for packaging heavy or abrasive items, thanks to its long fibers and unbleached nature. Bond paper, while smooth and strong enough for writing or printing, lacks the robust tensile strength of kraft paper and is more prone to tearing under stress. For applications requiring maximum durability and tear resistance, kraft paper provides superior protection for your products.

Environmental Impact and Sustainability

Kraft paper is produced from unbleached wood pulp, making it biodegradable and more eco-friendly due to its minimal chemical processing and higher recyclability compared to bond paper. Bond paper, typically made from bleached wood pulp, often involves more chemical treatments that can pose greater environmental concerns through increased energy consumption and potential pollution. Choosing kraft paper supports sustainability efforts by reducing waste and conserving resources, aligning with environmentally responsible practices.

Print Quality and Compatibility

Kraft paper offers a coarse texture and natural brown tone, which makes print quality less sharp and vibrant compared to bond paper's smooth, white surface designed for crisp, high-resolution printing. Bond paper is highly compatible with various printers, including inkjet and laser, ensuring clear text and images, while kraft paper's rough surface may cause smudging or uneven ink absorption. Your choice depends on whether you prioritize durability and rustic appeal or precise print clarity and compatibility with standard printing equipment.

Cost Differences and Affordability

Kraft paper generally costs less than bond paper due to its simpler manufacturing process and recycled content, making it a more affordable option for packaging and industrial uses. Bond paper, commonly used for printing and office documents, tends to be pricier because of its higher quality, smoother texture, and brightness. Choosing between the two depends on Your specific needs, with kraft paper offering economical durability and bond paper providing a professional finish at a higher price point.

Choosing the Right Paper for Your Needs

Kraft paper offers superior durability and eco-friendliness, making it ideal for packaging, wrapping, and craft projects, while bond paper provides a smooth finish perfect for professional documents and printing. Understanding your project's requirements, such as strength and visual quality, helps determine the best choice between the two. Your selection significantly impacts final presentation and functionality, ensuring optimal results for your needs.

Kraft paper vs bond paper Infographic

libmatt.com

libmatt.com