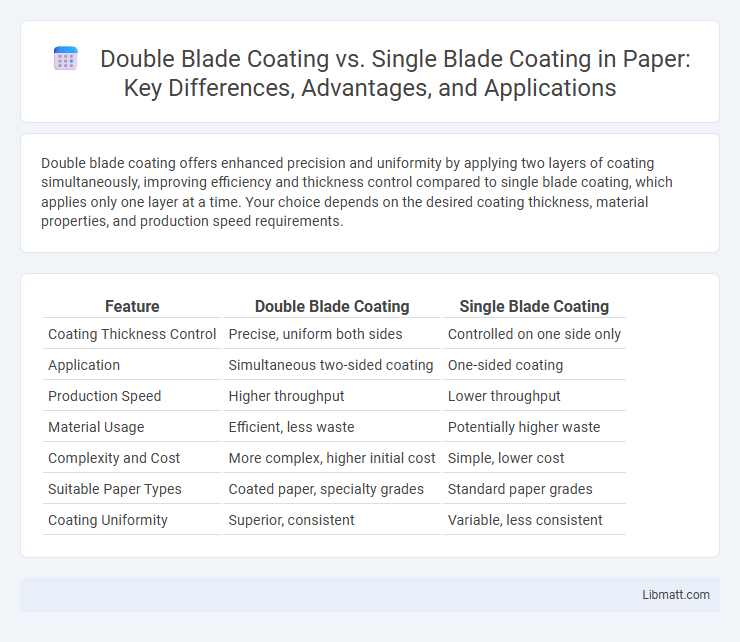

Double blade coating offers enhanced precision and uniformity by applying two layers of coating simultaneously, improving efficiency and thickness control compared to single blade coating, which applies only one layer at a time. Your choice depends on the desired coating thickness, material properties, and production speed requirements.

Table of Comparison

| Feature | Double Blade Coating | Single Blade Coating |

|---|---|---|

| Coating Thickness Control | Precise, uniform both sides | Controlled on one side only |

| Application | Simultaneous two-sided coating | One-sided coating |

| Production Speed | Higher throughput | Lower throughput |

| Material Usage | Efficient, less waste | Potentially higher waste |

| Complexity and Cost | More complex, higher initial cost | Simple, lower cost |

| Suitable Paper Types | Coated paper, specialty grades | Standard paper grades |

| Coating Uniformity | Superior, consistent | Variable, less consistent |

Introduction to Blade Coating Techniques

Double blade coating utilizes two blades to deposit simultaneous layers, increasing coating uniformity and thickness control, unlike single blade coating which applies one layer at a time. Single blade coating is simpler and more cost-effective for thin, uniform films, but often struggles with achieving consistent multi-layer structures. Double blade coating enhances material efficiency and is favored in advanced applications requiring precise layer stacking and improved surface quality.

Overview of Single Blade Coating

Single blade coating utilizes a single applicator blade to control the thickness and uniformity of liquid or slurry applied to a substrate. This method offers precise control over coating weight, making it ideal for applications requiring consistent film thickness such as adhesives, paints, and inks. Compared to double blade coating, single blade coating generally allows simpler equipment design and easier maintenance while maintaining high accuracy in coating layer thickness.

Fundamentals of Double Blade Coating

Double blade coating uses two parallel blades to apply a controlled thin film of liquid coating, enhancing uniformity and precision compared to single blade coating. This method enables better thickness control and increased coating speed, making it ideal for high-volume industrial applications requiring consistent film quality. Your production process benefits from reduced material waste and improved surface smoothness with the fundamentals of double blade coating.

Key Differences: Double vs Single Blade Coating

Double blade coating uses two blades to apply a more uniform and precise film thickness compared to single blade coating, which relies on one blade and may result in less consistent layers. Double blade systems offer better control over coating weight and smoother surfaces, making them ideal for high-quality applications requiring uniformity. Your production efficiency and product quality can significantly improve with double blade coating due to reduced material waste and enhanced precision.

Coating Uniformity and Thickness Control

Double blade coating provides superior coating uniformity and thickness control compared to single blade coating by allowing precise adjustment of the gap between blades, ensuring a consistent wet film thickness across the substrate. The dual-blade system minimizes edge bead formation and reduces thickness variations caused by blade deflection or substrate irregularities, resulting in enhanced film quality. Your process benefits from improved repeatability and reduced material waste due to the enhanced precision in controlling coating thickness.

Material Compatibility Comparison

Double blade coating offers superior material compatibility by enabling precise control over wet film thickness, making it ideal for a wide range of substrates such as flexible films, foils, and paper. Single blade coating is generally suited for simpler applications with uniform surfaces but can struggle with viscosity variations in complex materials. Your choice depends on the specific material properties and coating requirements for achieving optimal adhesion and uniformity.

Productivity and Processing Speed

Double blade coating significantly enhances productivity by applying two layers simultaneously, effectively doubling the coating speed compared to single blade systems. This technique reduces processing time, enabling faster production cycles while maintaining uniform film thickness and high-quality surface finishes. Your manufacturing process benefits from increased throughput and improved operational efficiency with double blade coating technology.

Cost Efficiency and Resource Utilization

Double blade coating enhances cost efficiency by enabling simultaneous application of coatings on both sides of a substrate, reducing processing time and energy consumption compared to single blade coating that applies on only one side. This method optimizes resource utilization by minimizing material waste and improving production throughput, leading to lower operational expenses. Consequently, industries adopting double blade coating achieve superior scalability and sustainability in manufacturing processes.

Common Applications in Industry

Double blade coating is commonly used in industries requiring precise control over film thickness and uniformity, such as battery manufacturing, pharmaceuticals, and food packaging. Single blade coating finds application in simpler processes like paper coating, adhesives, and textiles where cost-effectiveness and speed are prioritized. Your choice between these methods depends on the specific requirements for coating quality and production efficiency in your industry.

Choosing the Right Blade Coating Method

Double blade coating provides a uniform film thickness and improved surface finish compared to single blade coating, making it ideal for applications requiring precise control over coating layers. Single blade coating is simpler and more cost-effective, suitable for thicker coatings where minor variations in thickness are acceptable. Your choice depends on the desired coating uniformity, material properties, and production speed, with double blade offering superior precision and single blade catering to ease and cost efficiency.

Double blade coating vs single blade coating Infographic

libmatt.com

libmatt.com