Tearing resistance measures a material's ability to resist the propagation of a cut or tear, while tensile resistance evaluates its capacity to withstand a pulling force without breaking. Understanding the difference between these properties is crucial for selecting materials that ensure Your product durability under varying stress conditions.

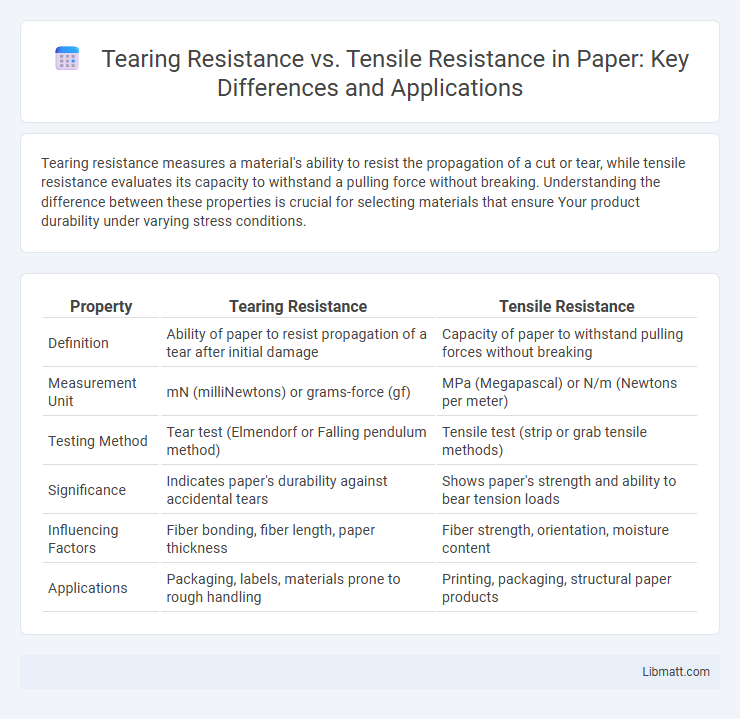

Table of Comparison

| Property | Tearing Resistance | Tensile Resistance |

|---|---|---|

| Definition | Ability of paper to resist propagation of a tear after initial damage | Capacity of paper to withstand pulling forces without breaking |

| Measurement Unit | mN (milliNewtons) or grams-force (gf) | MPa (Megapascal) or N/m (Newtons per meter) |

| Testing Method | Tear test (Elmendorf or Falling pendulum method) | Tensile test (strip or grab tensile methods) |

| Significance | Indicates paper's durability against accidental tears | Shows paper's strength and ability to bear tension loads |

| Influencing Factors | Fiber bonding, fiber length, paper thickness | Fiber strength, orientation, moisture content |

| Applications | Packaging, labels, materials prone to rough handling | Printing, packaging, structural paper products |

Understanding Tearing Resistance

Tearing resistance measures a material's ability to withstand the propagation of cuts or notches under stress, which is critical for applications subject to sudden impacts or sharp objects. Unlike tensile resistance, which evaluates a material's capacity to endure stretching forces before breaking, tearing resistance focuses on preventing the growth of existing flaws. High tearing resistance ensures durability and reliability in fabrics, rubber, and plastics used in protective gear and industrial components.

Defining Tensile Resistance

Tensile resistance refers to a material's ability to withstand forces that attempt to pull it apart or stretch it. This property measures the maximum stress a material can endure while being stretched before it breaks, making it essential for applications requiring durability under tension. Understanding tensile resistance helps you select materials that maintain integrity under load, ensuring performance and safety in structural and industrial uses.

Key Differences Between Tearing and Tensile Resistance

Tearing resistance measures a material's ability to withstand the propagation of a cut or tear, while tensile resistance reflects the maximum stress a material can endure when stretched before breaking. Tearing resistance is critical in applications where materials face sudden impacts or punctures, whereas tensile resistance is vital for load-bearing and structural integrity under continuous pulling forces. Your choice depends on whether durability against cuts or strength under tension is more relevant to your specific application.

Material Structures Affecting Resistance Properties

Material structures such as fiber orientation, molecular bonding, and crystallinity significantly influence tearing resistance and tensile resistance. High fiber alignment and strong intermolecular forces enhance tensile strength by resisting elongation, while toughness and energy absorption in the matrix contribute more to tearing resistance by preventing crack propagation. Variations in microstructure, such as the presence of voids or defects, can drastically reduce both resistances by facilitating stress concentration and crack initiation.

Measurement Methods: Tearing vs. Tensile Tests

Tearing resistance is commonly measured using the Elmendorf tear test, which evaluates the force required to propagate a tear in a material, providing insights into durability under sudden stress. Tensile resistance is determined through tensile tests, where a specimen is stretched until failure to assess its maximum load-bearing capacity and elongation properties. Both methods employ standardized testing protocols like ASTM D1922 for tearing and ASTM D638 for tensile testing to ensure consistent and comparable results across materials.

Common Applications Requiring High Tearing Resistance

Materials with high tearing resistance are essential in applications like outdoor gear, automotive upholstery, and industrial fabrics, where durability against sudden, forceful rips is crucial. These materials maintain integrity under sharp stress, making them ideal for protective clothing, tarps, and heavy-duty tents. Your choice of fabric or material must prioritize tearing resistance to ensure longevity and safety in demanding environments.

Industries Favoring High Tensile Resistance

Industries such as aerospace, automotive, and construction prioritize materials with high tensile resistance to ensure structural integrity under significant stress and load-bearing conditions. High tensile resistance is critical for components subjected to stretching, pulling, or tension forces, providing durability and safety in applications like vehicle frames, aircraft fuselages, and building reinforcements. Materials engineered for high tensile resistance contribute to longer service life and reduced risk of failure in demanding industrial environments.

Factors Influencing Tearing and Tensile Performance

Tearing resistance and tensile resistance are influenced by material composition, fiber orientation, and thickness, which affect durability and strength under different stress conditions. Environmental factors such as temperature, humidity, and exposure to chemicals also play a crucial role in altering the mechanical performance of materials. Understanding these factors helps you select the best material for applications requiring optimal tear and tensile resistance.

Enhancing Both Resistances in Materials Design

Enhancing tearing resistance and tensile resistance in materials design requires optimizing microstructural features such as fiber orientation, matrix toughness, and interfacial bonding strength. Incorporating high-performance reinforcements like carbon or aramid fibers improves load distribution and crack propagation resistance, directly boosting both tear and tensile strengths. Advanced composite formulations employing nanoscale fillers or hybrid matrix systems further synergize these properties for superior durability and mechanical performance.

Choosing the Right Material: Tearing Resistance vs. Tensile Resistance

Choosing the right material requires understanding the distinction between tearing resistance and tensile resistance, as both properties influence durability under different stresses. Tearing resistance measures a material's ability to withstand propagation of cuts or punctures, essential for applications subjected to sharp forces or impact. Tensile resistance, on the other hand, indicates the maximum stress a material can endure when stretched before breaking, critical for load-bearing and structural components.

Tearing resistance vs tensile resistance Infographic

libmatt.com

libmatt.com