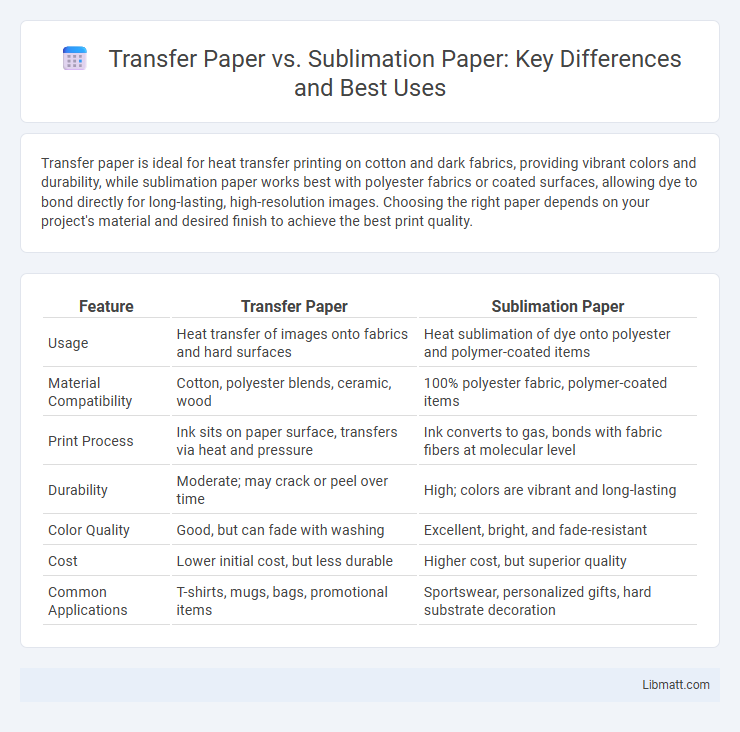

Transfer paper is ideal for heat transfer printing on cotton and dark fabrics, providing vibrant colors and durability, while sublimation paper works best with polyester fabrics or coated surfaces, allowing dye to bond directly for long-lasting, high-resolution images. Choosing the right paper depends on your project's material and desired finish to achieve the best print quality.

Table of Comparison

| Feature | Transfer Paper | Sublimation Paper |

|---|---|---|

| Usage | Heat transfer of images onto fabrics and hard surfaces | Heat sublimation of dye onto polyester and polymer-coated items |

| Material Compatibility | Cotton, polyester blends, ceramic, wood | 100% polyester fabric, polymer-coated items |

| Print Process | Ink sits on paper surface, transfers via heat and pressure | Ink converts to gas, bonds with fabric fibers at molecular level |

| Durability | Moderate; may crack or peel over time | High; colors are vibrant and long-lasting |

| Color Quality | Good, but can fade with washing | Excellent, bright, and fade-resistant |

| Cost | Lower initial cost, but less durable | Higher cost, but superior quality |

| Common Applications | T-shirts, mugs, bags, promotional items | Sportswear, personalized gifts, hard substrate decoration |

Introduction to Transfer Paper and Sublimation Paper

Transfer paper is designed for heat press applications to transfer images onto fabrics or surfaces using inkjet or laser printers, making it ideal for cotton and dark-colored materials. Sublimation paper works exclusively with sublimation inks and polyester fabrics, enabling vibrant, permanent prints by converting solid dye into gas without going through a liquid state. Understanding the differences between transfer paper and sublimation paper ensures you choose the right material to achieve superior print quality and durability for your projects.

How Transfer Paper Works

Transfer paper works by printing a mirrored image onto a special coated sheet, which is then heat-pressed onto fabric or other surfaces. The heat and pressure cause the ink or toner to transfer from the paper to the substrate, creating a vibrant and detailed design. Unlike sublimation paper, transfer paper is suitable for various materials including cotton and polyester blends, offering versatile printing options.

The Science Behind Sublimation Paper

Sublimation paper is engineered with a microporous coating that holds sublimation ink in a dry state, allowing it to release ink consistently when heated during the heat press process. This paper's ability to convert solid dye into gas without passing through a liquid phase enables vibrant, durable color transfer directly into polymer-coated surfaces. In contrast, transfer paper typically relies on a liquid-based ink that sits atop the surface and requires adhesive or heat to bond, resulting in less vivid and less durable prints.

Suitable Fabrics and Surfaces

Transfer paper works best on light-colored cotton, polyester blends, and other natural fibers, making it ideal for everyday garments and fabric surfaces. Sublimation paper requires 100% polyester fabrics or specially coated surfaces like ceramics or metals to ensure vibrant, durable prints with dye penetration. Your choice depends on the fabric composition and the desired application to achieve optimal print quality.

Color Vibrancy and Print Quality Comparison

Sublimation paper delivers superior color vibrancy and print quality compared to transfer paper, as it uses heat to infuse dye directly into the fibers of polyester or polymer-coated substrates, resulting in sharp, vivid images with excellent durability. Transfer paper relies on a surface-level ink transfer method, which can produce less saturated colors and may fade or crack over time, especially on cotton fabrics. For your projects requiring long-lasting, high-definition prints with vibrant colors, sublimation paper is the optimal choice.

Durability and Washability of Results

Sublimation paper produces prints that permanently bond with fabric fibers, ensuring superior durability and washability compared to transfer paper, which relies on a heat-applied adhesive layer that can peel or crack over time. Sublimated designs resist fading, cracking, and washing out even after numerous laundry cycles, making them ideal for long-lasting applications. Choosing sublimation paper enhances your product's lifespan and maintains vibrant colors through repeated washing.

Required Equipment and Setup

Transfer paper requires a standard inkjet or laser printer and a heat press or household iron for transferring the design onto fabric or other surfaces, making it accessible for beginners and small-scale projects. Sublimation paper demands a specialized sublimation printer using sublimation inks and a heat press capable of reaching higher temperatures to facilitate dye gas infusion into polyester-coated substrates. Proper ventilation and temperature control are critical for sublimation to prevent color distortion and achieve vibrant, long-lasting prints.

Cost Efficiency and Accessibility

Transfer paper generally offers greater cost efficiency for small-scale and hobbyist printing due to its lower initial investment and compatibility with standard inkjet printers. Sublimation paper, while typically more expensive and requiring specialized sublimation inks and printers, provides superior print quality and durability ideal for bulk production and commercial use. Accessibility favors transfer paper since it is widely available and easier to use without specialized equipment, whereas sublimation paper demands specific hardware and materials, limiting its accessibility and increasing overall setup costs.

Pros and Cons of Transfer Paper vs Sublimation Paper

Transfer paper offers versatility for printing on various fabrics, including cotton, with straightforward application and lower upfront costs; however, it may produce less vibrant and durable prints compared to sublimation paper. Sublimation paper excels in delivering high-quality, long-lasting, and vivid designs on polyester fabrics but requires specialized printers and limits fabric choice. Your decision depends on the fabric type, budget, and desired print quality for optimal results.

Choosing the Best Paper for Your Project

Choosing the best paper for your project depends on the final material and printing method; transfer paper works best on cotton and dark fabrics, while sublimation paper is ideal for polyester and light-colored surfaces. Transfer paper uses heat to transfer dye-based images, maintaining vibrant colors on natural fibers, whereas sublimation paper sublimates ink into polyester fibers for long-lasting, high-resolution prints. Your project's success hinges on selecting the right paper to ensure durability, color accuracy, and compatibility with the fabric type.

transfer paper vs sublimation paper Infographic

libmatt.com

libmatt.com