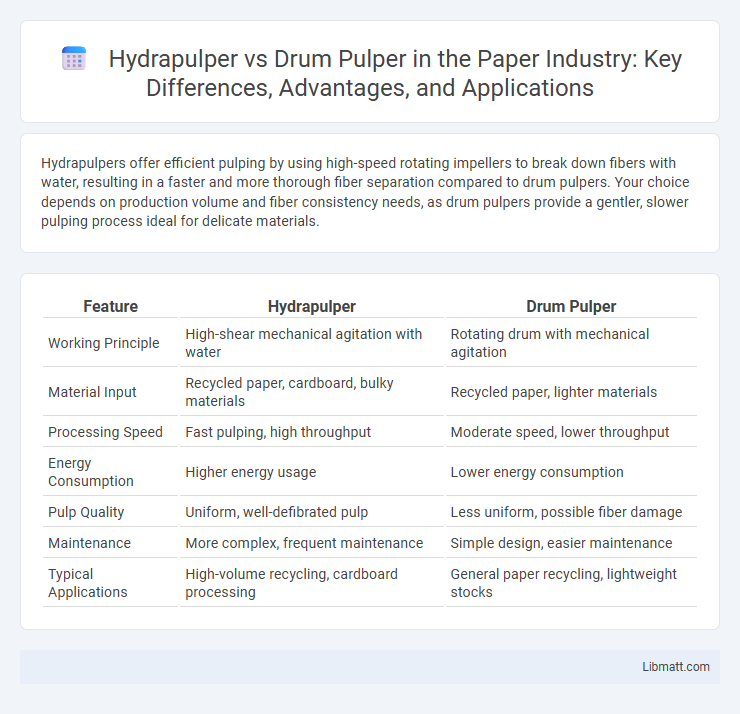

Hydrapulpers offer efficient pulping by using high-speed rotating impellers to break down fibers with water, resulting in a faster and more thorough fiber separation compared to drum pulpers. Your choice depends on production volume and fiber consistency needs, as drum pulpers provide a gentler, slower pulping process ideal for delicate materials.

Table of Comparison

| Feature | Hydrapulper | Drum Pulper |

|---|---|---|

| Working Principle | High-shear mechanical agitation with water | Rotating drum with mechanical agitation |

| Material Input | Recycled paper, cardboard, bulky materials | Recycled paper, lighter materials |

| Processing Speed | Fast pulping, high throughput | Moderate speed, lower throughput |

| Energy Consumption | Higher energy usage | Lower energy consumption |

| Pulp Quality | Uniform, well-defibrated pulp | Less uniform, possible fiber damage |

| Maintenance | More complex, frequent maintenance | Simple design, easier maintenance |

| Typical Applications | High-volume recycling, cardboard processing | General paper recycling, lightweight stocks |

Introduction to Pulping Technologies

Hydrapulpers and drum pulpers are essential pulp processing technologies widely used in the paper industry to separate fibers from raw materials. Hydrapulpers employ high-speed rotors to create a strong hydraulic action that efficiently breaks down recycled paper into pulp, while drum pulpers use rotating drums with perforated screens to disintegrate and classify fibers gently. Your choice between hydrapulper and drum pulper depends on factors like fiber quality, input material type, and overall production requirements.

What is a Hydrapulper?

A Hydrapulper is a high-efficiency machine used in the pulp and paper industry to break down recycled paper into a fibrous slurry, facilitating fiber separation for recycling. Unlike a drum pulper, it uses a rotor-driven mixing tank to quickly disintegrate fibers while minimizing damage, leading to improved pulp quality and higher yield. Your production process benefits from the Hydrapulper's ability to handle various waste paper grades with consistent energy consumption and ease of operation.

What is a Drum Pulper?

A drum pulper is a mechanical device used in the paper recycling industry to separate fibers from waste paper by immersing and agitating the material in water within a rotating drum. Unlike a hydrapulper, which uses high-pressure jets for fiber separation, the drum pulper relies on the drum's motion to break down and defiberize the pulp. Understanding the differences helps you choose the right equipment based on your production requirements and fiber recovery efficiency.

Key Differences Between Hydrapulper and Drum Pulper

Hydrapulpers use high-speed rotor blades to break down pulp fibers with water, providing efficient fiber separation and reducing contaminants, while drum pulpers rely on a rotating drum and stationary knife to mechanically disintegrate materials. The hydrapulper offers higher processing speeds and better fiber quality due to its intensified mixing action, whereas drum pulpers are simpler, more robust, and suitable for heavier, bulkier waste. Understanding these key differences helps you select the right pulping technology based on production volume and material characteristics.

Working Principles of Hydrapulper

Hydrapulpers operate by using high-speed rotating impellers to generate strong hydraulics and mechanical forces that break down raw materials into pulp. The mechanism relies on water currents and shear forces to disintegrate fibers efficiently within a large tank. This process enhances fiber separation, reduces contamination, and improves overall pulp quality compared to traditional drum pulpers.

Working Principles of Drum Pulper

Drum pulpers operate by rotating a large cylindrical drum containing water and raw material, using friction and mechanical agitation to separate fibers from contaminants. The rotating action breaks down materials efficiently, making it ideal for processing recycled paper and cardboard. Your choice between hydrapulper and drum pulper depends on the specific fiber separation needs and the type of raw material handled.

Efficiency and Energy Consumption

Hydrapulpers offer higher efficiency by rapidly breaking down fiber with minimal mechanical force, resulting in lower energy consumption per ton of processed material compared to drum pulpers. Drum pulpers require more energy due to prolonged mechanical agitation and slower fiber separation rates. The optimized energy use in hydrapulpers makes them preferable for large-scale pulp production aiming to reduce operational costs and environmental impact.

Applications and Material Compatibility

Hydrapulpers are ideal for processing waste materials like cardboard, mixed paper, and plastic films due to their high-intensity agitation that breaks down fibers efficiently, making them suitable for recycling and pulp production in large-scale applications. Drum pulpers, on the other hand, are better suited for handling lighter, less contaminated materials such as newspapers or office paper, providing gentle fiber separation with less mechanical wear. Your choice between hydrapulper and drum pulper should consider the type of feedstock and desired processing intensity to ensure optimal material compatibility and operational efficiency.

Maintenance and Operational Costs

Hydrapulpers typically have higher initial maintenance costs due to complex hydraulic systems but benefit from lower operational costs through efficient fiber dispersion and reduced downtime. Drum pulpers require simpler maintenance routines with fewer specialized parts, resulting in lower upfront expenses, yet they may incur higher operational costs because of greater energy consumption and less effective fiber separation. Your choice between these pulpers will significantly impact ongoing maintenance budgets and energy efficiency in pulp processing operations.

Choosing the Right Pulper for Your Needs

Selecting the right pulper depends on your material type and production scale, with hydrapulpers excelling in processing mixed office waste and deinking applications due to their efficient fiber recovery and lower energy consumption. Drum pulpers are more suitable for handling high-volume, less contaminated materials like corrugated containers, offering robust performance and durability under continuous operation. Evaluating factors such as feedstock consistency, desired pulp quality, and maintenance requirements ensures optimal choice between hydrapulper and drum pulper for tailored paper recycling processes.

Hydrapulper vs drum pulper Infographic

libmatt.com

libmatt.com