Coreboard offers superior strength and durability compared to chipboard, making it ideal for heavy-duty construction and furniture applications. If your project demands enhanced load-bearing capacity and longevity, coreboard is the better choice over chipboard, which is more affordable but less robust.

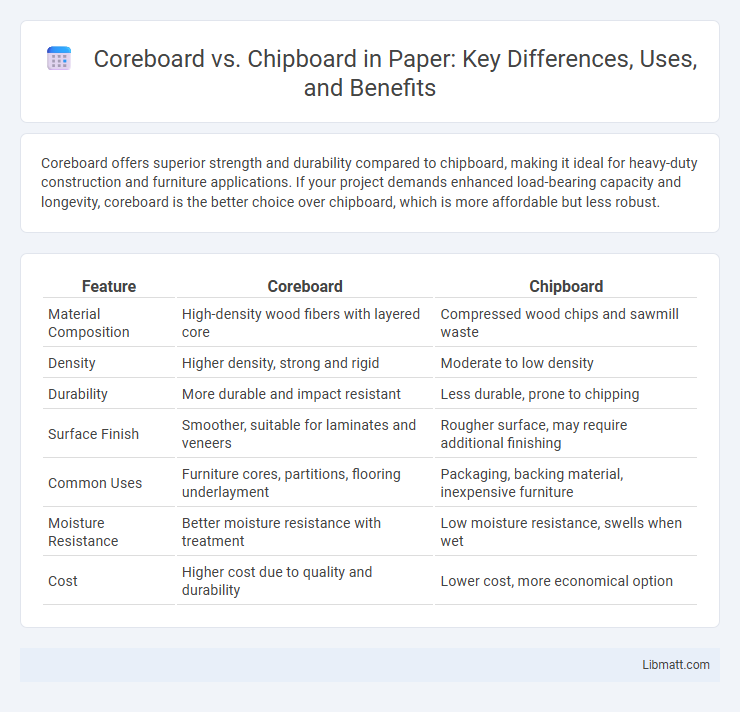

Table of Comparison

| Feature | Coreboard | Chipboard |

|---|---|---|

| Material Composition | High-density wood fibers with layered core | Compressed wood chips and sawmill waste |

| Density | Higher density, strong and rigid | Moderate to low density |

| Durability | More durable and impact resistant | Less durable, prone to chipping |

| Surface Finish | Smoother, suitable for laminates and veneers | Rougher surface, may require additional finishing |

| Common Uses | Furniture cores, partitions, flooring underlayment | Packaging, backing material, inexpensive furniture |

| Moisture Resistance | Better moisture resistance with treatment | Low moisture resistance, swells when wet |

| Cost | Higher cost due to quality and durability | Lower cost, more economical option |

Introduction to Coreboard and Chipboard

Coreboard and chipboard are engineered wood products primarily used in furniture and construction. Coreboard features a solid, dense core made from wood fibers or particles bonded under high pressure, offering strength and stability. Chipboard, also known as particleboard, consists of wood chips and resin compressed into sheets, providing a cost-effective, lightweight alternative with moderate durability.

Composition and Material Differences

Coreboard is typically composed of compressed wood fibers or veneer layers bonded with adhesives, providing a dense, smooth surface ideal for cabinetry and furniture. Chipboard, also known as particleboard, consists of wood chips, sawdust, and resin pressed together, creating a less dense and more porous material often used for inexpensive, lightweight furniture. Your choice between coreboard and chipboard depends on the desired strength, finish quality, and application durability.

Manufacturing Processes

Coreboard manufacturing involves compressing wood fibers or particles with adhesives under heat and pressure to create a dense, smooth surface ideal for cabinetry and furniture. Chipboard, also known as particleboard, is produced by bonding wood chips and resin with a hot press, resulting in a less dense, more economical material often used in furniture and flooring underlayment. Your choice between coreboard and chipboard depends on the desired strength, surface finish, and manufacturing quality needed for your project.

Physical Properties and Strength

Coreboard offers a denser and more uniform structure compared to chipboard, resulting in higher load-bearing capacity and improved resistance to bending. Chipboard, made from compressed wood chips and resin, tends to have lower mechanical strength and is more prone to moisture damage, leading to swelling and weakening over time. Your choice between coreboard and chipboard should consider the specific strength requirements and environmental exposure of your application.

Common Applications and Uses

Coreboard is commonly used in construction for wall partitioning, furniture manufacturing, and insulation due to its sturdy, dense composition offering excellent thermal and acoustic properties. Chipboard finds frequent application in affordable furniture production, flooring underlays, and cabinetry, valued for its cost-effectiveness and ease of machining. Both materials serve distinct functional roles in woodworking and building projects based on durability and budget requirements.

Environmental Impact and Sustainability

Coreboard offers a lower environmental impact compared to chipboard due to its use of sustainable and recycled materials, reducing waste and conserving natural resources. Chipboard often involves adhesives and resins derived from synthetic chemicals, which can contribute to higher emissions and limited recyclability. Sustainable production practices and the ability to recycle or biodegrade coreboard enhance its attractiveness as an eco-friendly alternative in packaging and construction industries.

Cost Comparison

Coreboard typically offers a higher cost compared to chipboard due to its superior density, durability, and smooth finish, making it ideal for high-end furniture and cabinetry. Chipboard is a more budget-friendly option, favored in projects where cost efficiency is crucial and surface quality is less critical. The choice between coreboard and chipboard depends largely on project requirements and financial constraints, with chipboard providing significant savings in large-scale or temporary constructions.

Durability and Longevity

Coreboard offers superior durability and longevity compared to chipboard due to its denser composition and higher-quality materials, making it more resistant to impact and moisture damage. Chipboard, often made from compressed wood particles and adhesives, tends to degrade faster when exposed to humidity and heavy use, resulting in a shorter lifespan. Therefore, coreboard is preferred for applications requiring sustained strength and durability over time.

Market Availability and Sizing Options

Coreboard and chipboard differ significantly in market availability and sizing options, with coreboard typically offered in standardized sheet sizes such as 4x8 feet and thicknesses ranging from 1/4 to 1 inch, catering to applications requiring smooth surfaces and structural integrity. Chipboard, also widely available, comes in a broader range of thicknesses and custom sizes, often favored for packaging and furniture backing due to its cost-effectiveness and versatility. Both materials are accessible through major building supply distributors and specialty retailers, though coreboard's precise manufacturing tolerances make it less customizable compared to the more adaptable chipboard sizing options.

Choosing Between Coreboard and Chipboard

Choosing between coreboard and chipboard depends on the specific application and desired properties such as strength, durability, and finish quality. Coreboard offers higher density and smoother surface, making it ideal for cabinetry, furniture, and projects requiring superior paint finishes. Chipboard, being more economical and made from compressed wood chips, suits budget-friendly applications like shelving and packaging where structural strength is less critical.

Coreboard vs chipboard Infographic

libmatt.com

libmatt.com