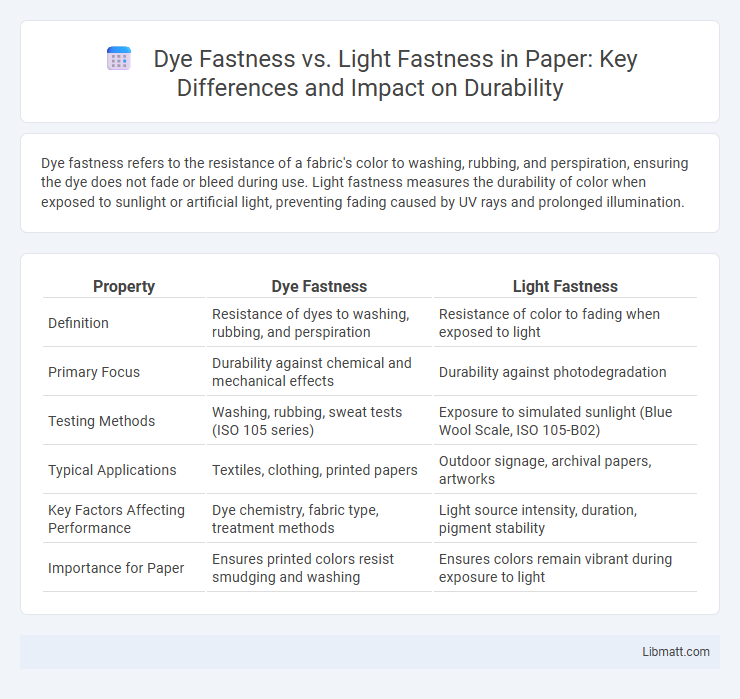

Dye fastness refers to the resistance of a fabric's color to washing, rubbing, and perspiration, ensuring the dye does not fade or bleed during use. Light fastness measures the durability of color when exposed to sunlight or artificial light, preventing fading caused by UV rays and prolonged illumination.

Table of Comparison

| Property | Dye Fastness | Light Fastness |

|---|---|---|

| Definition | Resistance of dyes to washing, rubbing, and perspiration | Resistance of color to fading when exposed to light |

| Primary Focus | Durability against chemical and mechanical effects | Durability against photodegradation |

| Testing Methods | Washing, rubbing, sweat tests (ISO 105 series) | Exposure to simulated sunlight (Blue Wool Scale, ISO 105-B02) |

| Typical Applications | Textiles, clothing, printed papers | Outdoor signage, archival papers, artworks |

| Key Factors Affecting Performance | Dye chemistry, fabric type, treatment methods | Light source intensity, duration, pigment stability |

| Importance for Paper | Ensures printed colors resist smudging and washing | Ensures colors remain vibrant during exposure to light |

Introduction to Dye Fastness and Light Fastness

Dye fastness measures a fabric's resistance to fading or running during washing, rubbing, or exposure to chemicals, ensuring the color remains vibrant over time. Light fastness evaluates the durability of a dye when exposed to sunlight or artificial light, preventing color degradation caused by UV rays. Both properties are critical for maintaining textile quality and longevity in various applications, from fashion to upholstery.

Defining Dye Fastness

Dye fastness refers to the resistance of a fabric's color to fading or running when exposed to various conditions such as washing, rubbing, or perspiration. Unlike light fastness, which specifically measures color retention when exposed to light, dye fastness encompasses a broader range of durability factors affecting your textiles. Understanding dye fastness helps you select materials that maintain their appearance and longevity through everyday use and care.

What is Light Fastness?

Light fastness measures a material's resistance to fading or color change when exposed to light, particularly ultraviolet (UV) rays. It is crucial for textiles, paintings, and printed materials to maintain their original appearance over time. You should consider light fastness ratings to ensure durability and longevity of colors under various lighting conditions.

Key Differences Between Dye Fastness and Light Fastness

Dye fastness measures the resistance of a fabric's color to washing, rubbing, and perspiration, while light fastness assesses how well the color withstands exposure to light, especially sunlight. Materials with high dye fastness maintain vibrant colors through cleaning and wear, whereas strong light fastness prevents fading or discoloration caused by UV rays. Understanding these key differences helps you select textiles that retain color quality under specific environmental conditions.

Factors Affecting Dye Fastness

Factors affecting dye fastness include fiber type, dye class, and fixation method, which determine how well the dye bonds to the fabric. Environmental conditions such as exposure to washing, perspiration, and abrasion also impact dye durability. Your choice of dye and fabric treatment directly influences the longevity and resistance of the color against fading.

Factors Influencing Light Fastness

Light fastness is primarily influenced by the chemical composition of dyes and their ability to resist photodegradation when exposed to ultraviolet (UV) radiation. Fabric type, including fiber absorbency and weave density, affects light fastness by impacting how dyes bond and shield against UV rays. Environmental conditions such as exposure duration, sunlight intensity, and atmospheric pollutants further modify the degree of light fastness in dyed textiles.

Testing Methods for Dye and Light Fastness

Testing methods for dye fastness include abrasion, washing, and perspiration tests to evaluate color durability under mechanical and chemical stress. Light fastness is primarily assessed through exposure to controlled artificial light sources, such as Xenon arc or UV lamps, to measure color fading over time. International standards like ISO 105-B02 for light fastness and ISO 105-C06 for washing fastness provide precise protocols ensuring consistent and reliable results.

Importance in Textile and Fashion Industries

Dye fastness and light fastness are critical factors in the textile and fashion industries, directly impacting the durability and aesthetic quality of fabrics. High dye fastness ensures that colors remain vibrant without bleeding or fading during washing, while strong light fastness prevents discoloration and degradation when exposed to sunlight. These properties are essential for maintaining product longevity, consumer satisfaction, and brand reputation in competitive markets.

Improving Fastness: Techniques and Innovations

Improving dye fastness and light fastness involves advanced techniques such as the use of UV absorbers, anti-fading agents, and nano-coatings that protect textiles from degradation caused by sunlight and washing. Innovations in textile chemistry include the development of reactive dyes with stronger molecular bonds and protective polymer layers that enhance resistance to fading. Your fabrics can achieve longer-lasting color vibrancy by selecting treatments tailored to specific material types and exposure conditions.

Conclusion: Choosing the Right Fastness for Your Needs

Dye fastness determines how well a color resists fading during washing, rubbing, or exposure to chemicals, while light fastness measures resistance to fading under prolonged exposure to sunlight or artificial light. Selecting the right fastness depends on the fabric's intended use, with higher dye fastness preferred for garments subjected to frequent cleaning and higher light fastness essential for outdoor textiles or display materials exposed to natural light. Understanding the specific fastness requirements ensures durability and color retention tailored to the product's functional environment.

dye fastness vs light fastness Infographic

libmatt.com

libmatt.com