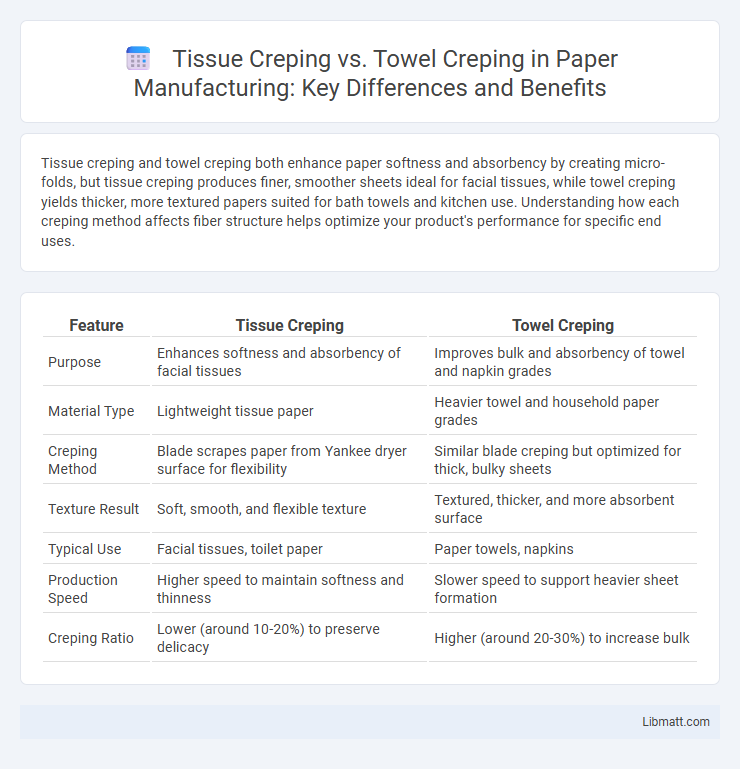

Tissue creping and towel creping both enhance paper softness and absorbency by creating micro-folds, but tissue creping produces finer, smoother sheets ideal for facial tissues, while towel creping yields thicker, more textured papers suited for bath towels and kitchen use. Understanding how each creping method affects fiber structure helps optimize your product's performance for specific end uses.

Table of Comparison

| Feature | Tissue Creping | Towel Creping |

|---|---|---|

| Purpose | Enhances softness and absorbency of facial tissues | Improves bulk and absorbency of towel and napkin grades |

| Material Type | Lightweight tissue paper | Heavier towel and household paper grades |

| Creping Method | Blade scrapes paper from Yankee dryer surface for flexibility | Similar blade creping but optimized for thick, bulky sheets |

| Texture Result | Soft, smooth, and flexible texture | Textured, thicker, and more absorbent surface |

| Typical Use | Facial tissues, toilet paper | Paper towels, napkins |

| Production Speed | Higher speed to maintain softness and thinness | Slower speed to support heavier sheet formation |

| Creping Ratio | Lower (around 10-20%) to preserve delicacy | Higher (around 20-30%) to increase bulk |

Introduction to Tissue Creping and Towel Creping

Tissue creping and towel creping are two essential processes in paper manufacturing that significantly impact the texture and absorbency of the final product. Tissue creping involves a blade scraping the paper off a dryer cylinder to create softness and stretch, which is ideal for facial tissues, while towel creping focuses on enhancing absorbency and strength, which is critical for paper towels. Understanding these differences helps you select the right product based on your specific needs for softness or absorbency.

Definition and Process of Tissue Creping

Tissue creping is a mechanical process in tissue manufacturing where the paper sheet is scraped from a revolving Yankee dryer using a creping blade, creating a soft, stretchable texture essential for products like facial tissues and toilet paper. This process increases bulk, softness, and absorbency by micro-folding the fibers, enhancing the tactile quality without compromising strength. Unlike towel creping, which is designed to improve durability and water absorption for heavier-duty products like paper towels, tissue creping specifically targets lightweight, delicate tissue grades for a gentle finish.

Definition and Process of Towel Creping

Towel creping is a drying process used in tissue production where the paper web is dried on a heated, rotating cylinder called a Yankee dryer and then scraped off with a creping blade. This process imparts softness, bulk, and stretch to the tissue by breaking the fibers and creating microfolds, distinguishing it from tissue creping, which may involve different creping methods or fabrics. Your tissue products benefit from enhanced absorbency and improved tactile properties due to the unique mechanical action of towel creping.

Key Differences Between Tissue and Towel Creping

Tissue creping involves creating a softer, more flexible paper by lightly scraping the dried paper web off the dryer cylinder, enhancing softness and absorbency for facial tissues and toilet paper. Towel creping applies a more aggressive creping process to produce bulkier, stronger, and more absorbent paper towels designed for heavy-duty drying and scrubbing tasks. Your choice between tissue and towel creping should consider the desired texture, strength, and absorbency properties tailored to specific applications.

Equipment Used in Tissue vs. Towel Creping

Tissue creping primarily utilizes Yankee dryers and doctor blades designed for soft, lightweight paper, ensuring smooth and flexible tissue production with precise blade angle and pressure adjustments. In towel creping, equipment includes enhanced Yankee dryers paired with robust creping blades optimized for thicker, more absorbent paper grades, facilitating higher bulk and strength. Both processes rely on customized creping parameters and specialized machinery to achieve distinct creping textures suitable for tissue and towel products.

Impact on Product Texture and Softness

Tissue creping produces a finer, more uniform texture that enhances softness, making it ideal for delicate facial tissues and toilet paper. Towel creping creates a thicker, more pronounced texture with increased bulk and absorbency, which improves the softness and durability of paper towels. Your choice between tissue and towel creping directly affects the balance between softness and strength in the final product.

Strength and Durability: A Comparative Analysis

Tissue creping enhances softness and flexibility but may reduce strength and durability compared to towel creping, which imparts higher tensile strength and improved abrasion resistance due to its stiffer crepe structure. Towel creping's robust fiber bonding makes it ideal for heavy-duty applications requiring longevity and resilience, while tissue creping suits delicate uses prioritizing gentleness over durability. Understanding these differences helps you select the appropriate creping method to balance softness with material strength in your product design.

Applications in Paper Manufacturing

Tissue creping is primarily used in the production of facial tissues, toilet papers, and napkins, enhancing softness, absorbency, and flexibility by creating micro-folds in the paper structure. Towel creping targets paper towels and industrial wipes, increasing bulk, strength, and water absorption capacity through more pronounced crepe patterns. Both techniques optimize paper performance tailored to specific end-use applications in hygiene and cleaning products.

Sustainability and Environmental Considerations

Tissue creping uses lower energy and water consumption processes compared to towel creping, reducing the overall environmental footprint in paper production. Towel creping typically involves higher mechanical action and chemical use, leading to increased resource consumption and potential emissions. Sustainable practices in tissue creping promote recycling and biodegradable product development, aligning with eco-friendly manufacturing standards.

Future Trends in Creping Techniques

Future trends in creping techniques emphasize advanced control over tissue creping and towel creping processes to enhance quality and efficiency. Innovations in creping blades, automation, and real-time monitoring are expected to optimize creping angles and adhesive properties, resulting in improved softness, bulk, and strength for both tissue and towel products. You can anticipate more sustainable, energy-efficient operations driven by these technological advancements, meeting growing consumer demand for premium paper goods.

Tissue creping vs towel creping Infographic

libmatt.com

libmatt.com