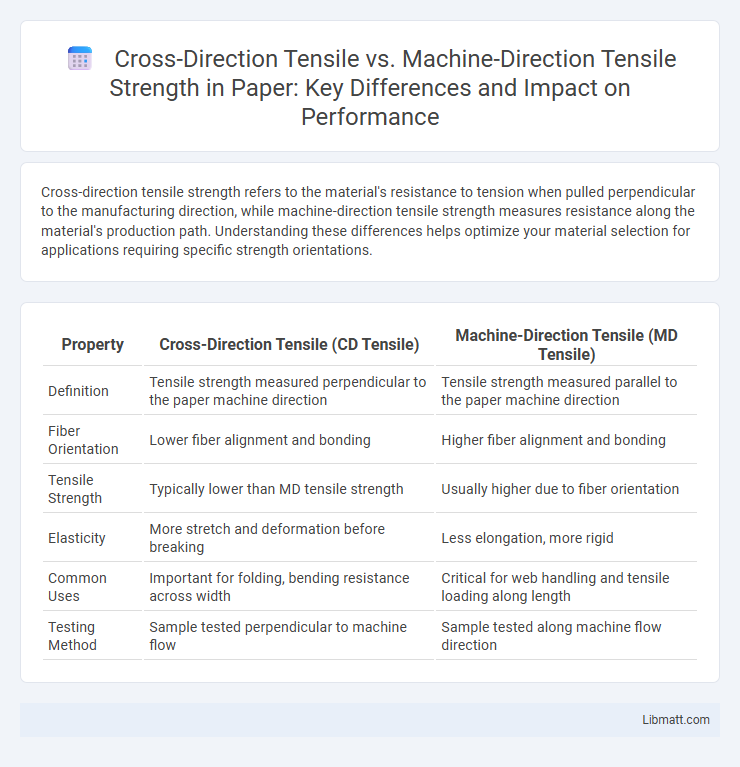

Cross-direction tensile strength refers to the material's resistance to tension when pulled perpendicular to the manufacturing direction, while machine-direction tensile strength measures resistance along the material's production path. Understanding these differences helps optimize your material selection for applications requiring specific strength orientations.

Table of Comparison

| Property | Cross-Direction Tensile (CD Tensile) | Machine-Direction Tensile (MD Tensile) |

|---|---|---|

| Definition | Tensile strength measured perpendicular to the paper machine direction | Tensile strength measured parallel to the paper machine direction |

| Fiber Orientation | Lower fiber alignment and bonding | Higher fiber alignment and bonding |

| Tensile Strength | Typically lower than MD tensile strength | Usually higher due to fiber orientation |

| Elasticity | More stretch and deformation before breaking | Less elongation, more rigid |

| Common Uses | Important for folding, bending resistance across width | Critical for web handling and tensile loading along length |

| Testing Method | Sample tested perpendicular to machine flow | Sample tested along machine flow direction |

Introduction to Tensile Properties in Materials

Tensile properties in materials describe their ability to withstand forces that attempt to stretch or pull them apart. Cross-direction tensile strength measures resistance perpendicular to the material's production direction, while machine-direction tensile strength gauges resistance along the production path. Understanding these differences helps you assess material performance and durability in various applications.

Defining Cross-Direction and Machine-Direction

Cross-direction tensile strength refers to the resistance of a material to tension applied perpendicular to the direction of production, often across the width of a web or sheet. Machine-direction tensile strength measures the material's ability to withstand tension along the direction in which it was manufactured, typically aligned with the flow of the production process. These distinct orientations impact the mechanical properties and performance of materials such as paper, film, and textiles, influencing durability and flexibility.

Importance of Tensile Strength in Industry

Tensile strength in both cross-direction (CD) and machine-direction (MD) is crucial for industries such as paper manufacturing, textiles, and packaging, where material durability and performance under stress determine product quality. CD tensile strength measures resistance to forces perpendicular to the production flow, affecting tear resistance and flexibility, while MD tensile strength evaluates strength along the production line, influencing elongation and tensile load capacity. Optimizing both tensile directions ensures reliable material behavior during processing, handling, and end-use, directly impacting efficiency and safety in industrial applications.

Measuring Cross-Direction Tensile Strength

Measuring cross-direction tensile strength involves applying force perpendicular to the machine direction of a material, such as paper or film, to evaluate its resistance to breaking under tension. Specialized tensile testing machines equipped with clamps hold samples and gradually increase the load until failure, providing accurate values for cross-direction tensile strength. This measurement is critical for assessing material durability and performance in applications where stress is applied across the width rather than along the production flow.

Measuring Machine-Direction Tensile Strength

Measuring machine-direction tensile strength involves assessing the resistance of a material, such as film or paper, to forces applied parallel to the manufacturing process. This test provides critical data on your material's elongation, yield strength, and ultimate tensile strength, essential for quality control and performance prediction in production. Accurate machine-direction tensile strength measurements ensure reliability and consistency in applications where directional durability is crucial.

Key Differences: Cross-Direction vs Machine-Direction Tensile

Cross-direction tensile strength measures the resistance of a material to force applied perpendicular to the manufacturing direction, while machine-direction tensile strength evaluates resistance parallel to the production line. The key difference lies in the anisotropic behavior of materials like paper or films, where machine-direction tensile typically exhibits higher strength due to fiber alignment during processing. Understanding these differences is crucial for applications requiring specific mechanical performance and durability.

Factors Affecting Directional Tensile Strength

Directional tensile strength in materials like paper or films varies significantly due to fiber orientation, processing methods, and environmental conditions. Machine-direction tensile strength is often higher because fibers align with the production flow, enhancing load resistance, while cross-direction strength depends on fiber bonding and cross-linking. Understanding these factors helps you optimize material performance by tailoring manufacturing parameters to balance strength in both directions.

Applications and Implications in Manufacturing

Cross-direction tensile strength influences the durability of materials used in flexible packaging and textiles, where lateral stress resistance is critical for product performance. Machine-direction tensile strength affects the efficiency and quality of processes such as paper production and film extrusion, where materials are subjected to tension along the production line. Understanding the balance between these tensile properties guides manufacturers in optimizing material selection and process parameters to enhance final product reliability and reduce waste.

Common Challenges and Solutions

Cross-direction tensile strength often exhibits greater variability than machine-direction tensile strength due to fiber orientation inconsistencies. Common challenges include uneven stress distribution and anisotropy, which can compromise material performance during processing and end-use. Optimizing fiber alignment and employing advanced testing methods help ensure your product meets industry-standard tensile strength requirements in both directions.

Future Trends in Tensile Testing and Material Design

Future trends in tensile testing emphasize advancements in cross-direction (CD) and machine-direction (MD) tensile analysis to enhance material performance prediction. Emerging techniques integrate real-time data from CD and MD tensile tests with machine learning algorithms, enabling precise material design tailored to specific applications. By leveraging these innovations, your material development can achieve optimized strength and flexibility, meeting evolving industry standards.

Cross-direction tensile vs machine-direction tensile Infographic

libmatt.com

libmatt.com