Bulk and density are key paper properties where bulk refers to the thickness of a sheet relative to its basis weight, indicating the paper's volume per unit weight, while density measures the mass per unit volume of the paper. Understanding these properties helps you select the right paper for printing or packaging, balancing rigidity and weight for optimal performance.

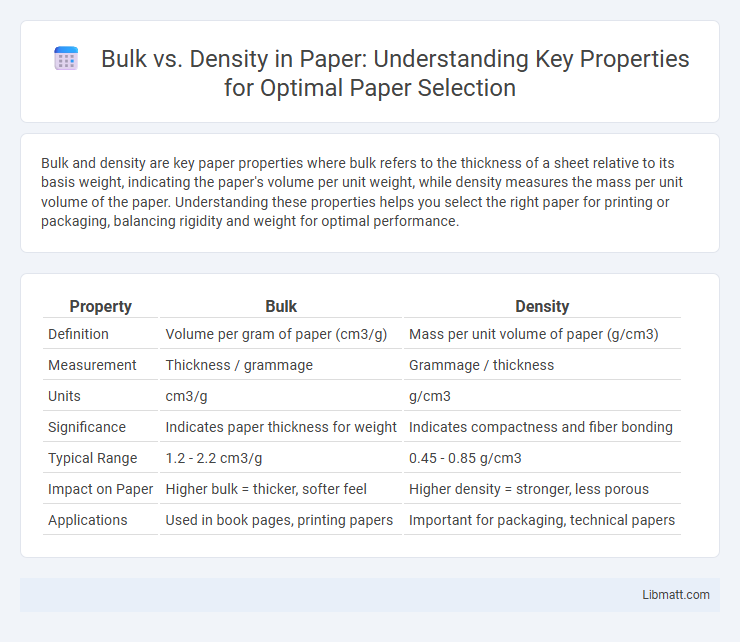

Table of Comparison

| Property | Bulk | Density |

|---|---|---|

| Definition | Volume per gram of paper (cm3/g) | Mass per unit volume of paper (g/cm3) |

| Measurement | Thickness / grammage | Grammage / thickness |

| Units | cm3/g | g/cm3 |

| Significance | Indicates paper thickness for weight | Indicates compactness and fiber bonding |

| Typical Range | 1.2 - 2.2 cm3/g | 0.45 - 0.85 g/cm3 |

| Impact on Paper | Higher bulk = thicker, softer feel | Higher density = stronger, less porous |

| Applications | Used in book pages, printing papers | Important for packaging, technical papers |

Understanding Bulk and Density in Paper

Bulk and density are critical paper properties that impact its thickness and weight, influencing print quality and handling. Bulk refers to the paper's thickness relative to its basis weight, indicating how voluminous the sheet feels, while density measures the paper's mass per unit volume, affecting rigidity and opacity. Understanding these properties helps you select the right paper for specific applications, ensuring optimal performance and appearance in printing and packaging.

Defining Bulk: What Does It Mean for Paper?

Bulk in paper refers to the thickness of a sheet relative to its weight, indicating how much space the paper occupies without necessarily increasing its density. It measures the volume per unit weight, affecting the paper's stiffness, opacity, and printability, which are critical for your specific printing or packaging needs. Understanding bulk helps in selecting paper that balances durability with lightweight characteristics to optimize performance and cost-efficiency.

The Science Behind Paper Density

Paper density, measured in grams per cubic centimeter (g/cm3), represents the mass of paper per unit volume and directly influences its stiffness and durability. Bulk refers to the thickness of paper per unit weight, reflecting the volume occupied by fibers and the air within the sheet. Understanding the relationship between bulk and density is essential for optimizing paper quality, balancing weight, thickness, and performance in printing and packaging applications.

Bulk vs. Density: Key Differences

Bulk and density are related but distinct paper properties; bulk measures the thickness of paper relative to its basis weight, while density quantifies the compactness of fibers within the paper. Higher bulk indicates a thicker, less dense sheet that can provide a softer feel and improved opacity, whereas higher density results in a thinner, more rigid sheet with greater strength. Understanding these key differences helps you select the right paper for printing, packaging, or other specific applications requiring particular stiffness and weight characteristics.

Measuring Bulk and Density in Laboratory Settings

Measuring bulk and density in laboratory settings involves calculating the volume and mass relationship of paper samples to assess thickness and compactness accurately. Bulk is determined by dividing the caliper (thickness) of the paper by its grammage (basis weight), while density is calculated by dividing the grammage by the bulk. Your precise measurement of these properties is essential for quality control, influencing paper performance in printing and packaging applications.

The Impact of Bulk and Density on Print Quality

Bulk and density significantly influence print quality by affecting paper thickness and stiffness, which determine how well ink adheres and dries. Higher bulk typically means a thicker paper with more air space, enhancing opacity and reducing show-through, while higher density indicates tightly packed fibers that improve surface smoothness and sharpness of printed images. Your choice between bulk and density balances durability with print clarity, ensuring optimal results for specific printing applications.

Bulk and Density in Packaging Applications

Bulk and density critically affect the performance and cost-efficiency of packaging materials by determining the paper's thickness and weight per unit volume. Higher bulk paper offers better cushioning and rigidity without significantly increasing weight, making it ideal for protective packaging. Conversely, density influences the compactness and durability of the material, impacting stacking strength and overall package integrity.

How Bulk and Density Affect Paper Strength

Bulk and density are critical factors influencing paper strength, where higher density typically indicates more fiber bonding, enhancing tensile and bursting strength. Papers with greater bulk tend to have thicker caliper and improved cushioning but may exhibit lower strength due to less fiber compaction. Optimizing the balance between bulk and density ensures paper maintains sufficient durability while meeting specific performance requirements in packaging and printing applications.

Choosing the Right Balance for Specific Uses

Selecting the optimal balance between bulk and density in paper hinges on the intended application, as higher bulk paper offers better cushioning and opacity, ideal for packaging and printing. Conversely, denser paper improves stiffness and durability, making it suitable for books and premium stationery. Understanding the trade-offs between bulk's volume and density's mass per unit volume ensures functionality tailored to specific industry requirements.

Innovations in Paper Manufacturing: Optimizing Bulk and Density

Innovations in paper manufacturing focus on optimizing bulk and density to enhance product performance and sustainability. Advanced fiber treatments and refined calendering techniques enable manufacturers to produce paper with higher bulk without compromising strength, improving printability and tactile quality. You benefit from these innovations through more durable, lightweight paper products that reduce material use and shipping costs.

Bulk vs density (paper properties) Infographic

libmatt.com

libmatt.com