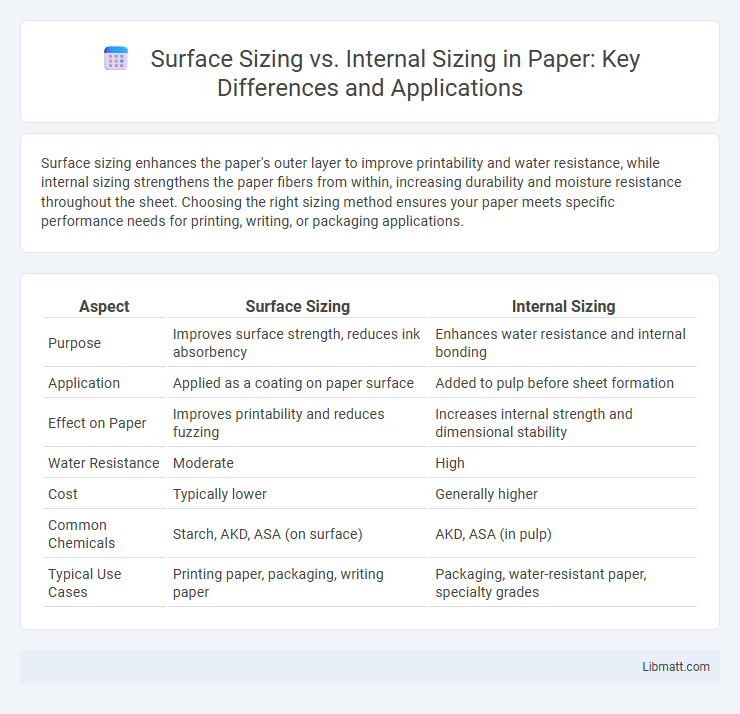

Surface sizing enhances the paper's outer layer to improve printability and water resistance, while internal sizing strengthens the paper fibers from within, increasing durability and moisture resistance throughout the sheet. Choosing the right sizing method ensures your paper meets specific performance needs for printing, writing, or packaging applications.

Table of Comparison

| Aspect | Surface Sizing | Internal Sizing |

|---|---|---|

| Purpose | Improves surface strength, reduces ink absorbency | Enhances water resistance and internal bonding |

| Application | Applied as a coating on paper surface | Added to pulp before sheet formation |

| Effect on Paper | Improves printability and reduces fuzzing | Increases internal strength and dimensional stability |

| Water Resistance | Moderate | High |

| Cost | Typically lower | Generally higher |

| Common Chemicals | Starch, AKD, ASA (on surface) | AKD, ASA (in pulp) |

| Typical Use Cases | Printing paper, packaging, writing paper | Packaging, water-resistant paper, specialty grades |

Introduction to Paper Sizing

Paper sizing enhances durability and print quality by controlling the paper's absorbency through either surface sizing or internal sizing techniques. Surface sizing applies a protective coating to the paper's exterior, improving ink holdout and surface strength, while internal sizing integrates sizing agents into the pulp, ensuring moisture resistance and dimensional stability throughout the sheet. Understanding the differences between these methods helps you choose the right paper type for specific printing and packaging applications.

What is Surface Sizing?

Surface sizing is a paper treatment process that involves applying a thin layer of sizing agents, such as starch or synthetic polymers, to the paper's exterior surface to enhance its strength, smoothness, and printability. This treatment improves the paper's resistance to ink absorption, resulting in sharper images and reduced smudging during printing. Surface sizing is essential for producing high-quality printing papers, packaging materials, and specialty papers where surface properties are critical.

What is Internal Sizing?

Internal sizing is a paper manufacturing process that involves adding sizing agents directly into the pulp to enhance the paper's resistance to water and ink absorption from within. This method improves the paper's overall strength and printability by chemically modifying the fibers before sheet formation. Your choice of internal sizing influences the paper's durability, ink holdout, and suitability for various printing techniques.

Key Differences between Surface and Internal Sizing

Surface sizing primarily enhances the paper's strength, printability, and surface smoothness by applying a sizing agent to the exterior, improving ink holdout and resistance to moisture. Internal sizing modifies the paper fibers during the pulp stage, imparting water repellency and improved bulk and stiffness throughout the sheet. Key differences include application timing--surface sizing occurs after sheet formation while internal sizing is integrated during papermaking--and the type of additives used, with surface sizing involving starch or synthetic polymers and internal sizing typically utilizing rosin or alkyl ketene dimer (AKD).

Advantages of Surface Sizing

Surface sizing improves paper strength and printability by applying a thin layer of sizing agents on the paper's exterior, enhancing ink holdout and reducing feathering. It increases resistance to surface wear and water penetration without significantly affecting paper bulk or stiffness, making it ideal for high-quality printing and writing papers. Your documents benefit from sharper images and smoother finishes, providing superior performance in printing and coating applications.

Advantages of Internal Sizing

Internal sizing enhances paper strength and water resistance by integrating sizing agents directly into the pulp during production, preventing fiber swelling and improving durability. This method ensures uniform sizing throughout the paper, leading to better print quality and increased resistance to ink penetration. You gain improved bulk and stiffness without compromising the paper's surface smoothness, making it ideal for various printing and packaging applications.

Applications of Surface Sizing

Surface sizing enhances paper properties such as smoothness, printability, and strength, making it ideal for high-quality printing, packaging, and writing papers. It involves applying surface chemicals like starch or synthetic polymers to improve ink holdout and reduce dusting, crucial for newspapers, magazines, and coated papers. Your choice of surface sizing directly impacts the paper's performance in digital and offset printing applications, ensuring better image clarity and durability.

Applications of Internal Sizing

Internal sizing is primarily used in papermaking to enhance the paper's resistance to water and ink penetration, improving print quality and durability. Your applications include packaging materials, postcards, and high-quality writing paper where moisture resistance and surface strength are critical. This treatment helps maintain paper integrity in environments exposed to humidity, making it essential for products requiring long-lasting performance.

Impact on Paper Properties

Surface sizing enhances paper strength, smoothness, and printability by creating a protective layer that resists ink penetration and water absorption on the paper's exterior. Internal sizing improves overall paper durability and resistance to liquid penetration by modifying fiber properties throughout the sheet, affecting bulk, stiffness, and folding endurance. Understanding the differences allows you to select the best sizing technique to optimize your paper's performance for specific applications.

Choosing the Right Sizing Method

Choosing the right sizing method depends on the intended paper use; surface sizing enhances printability and reduces ink absorption by applying a thin starch or synthetic layer on paper surfaces, while internal sizing improves paper strength and water resistance by incorporating sizing agents during pulp formation. Surface sizing suits applications requiring smoothness and high-quality printing, whereas internal sizing is ideal for products needing durability and resistance to liquid penetration. Evaluating the balance between print performance and physical properties ensures optimal sizing selection for specific paper manufacturing needs.

Surface sizing vs internal sizing Infographic

libmatt.com

libmatt.com